Ito sputtering target and method for manufacturing same, ito transparent electroconductive film, and method for manufacturing ito transparent electroconductive film

A technology of transparent conductive film and manufacturing method, which is applied in the field of ITO sputtering target, can solve problems such as large grain size, achieve high density, guarantee improvement and reliability, and excellent reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

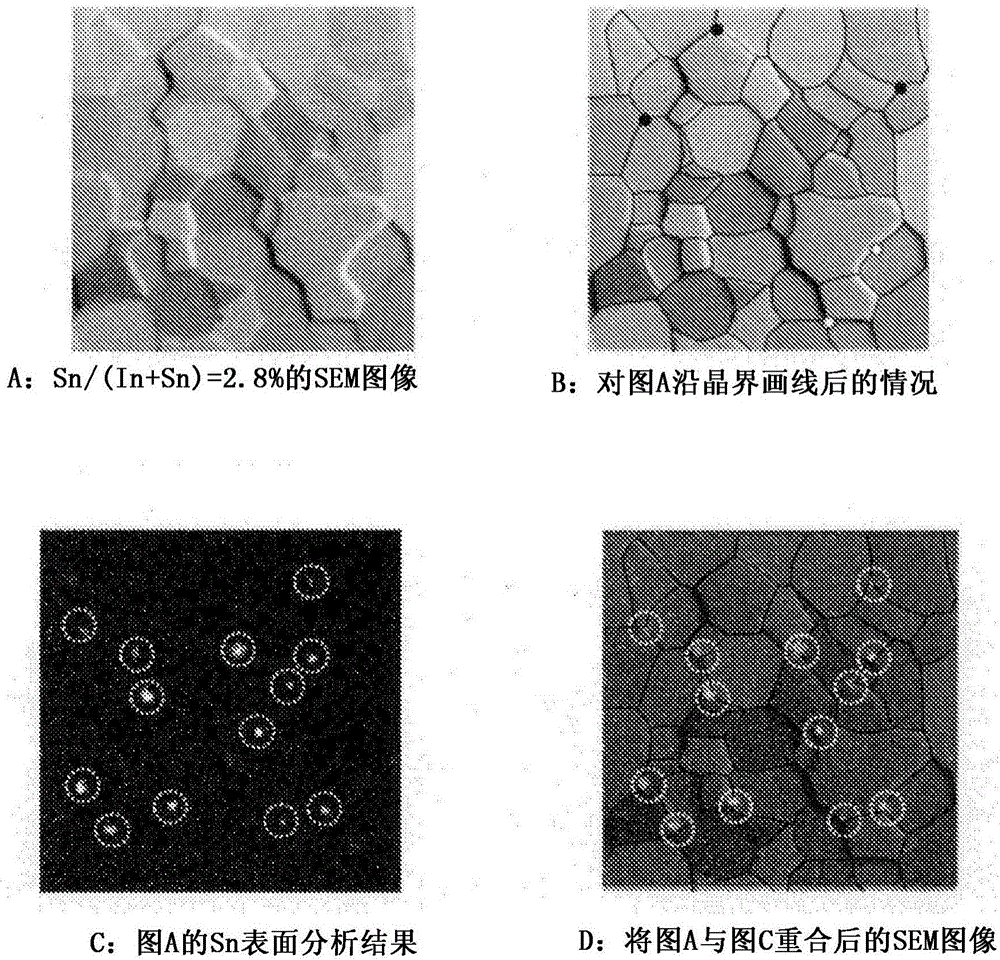

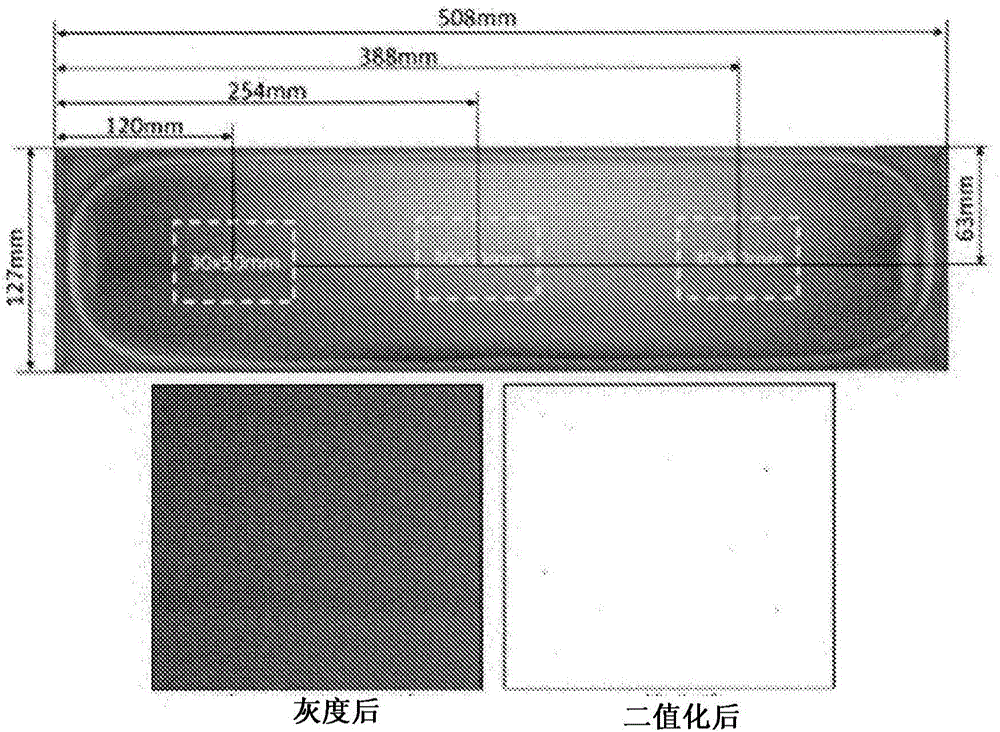

[0113] Use SnO whose ratio is adjusted so that Sn / (In+Sn) is 2.8% in atomic ratio 2 Powder and In 2 o 3 The powder was sintered in an oxygen atmosphere as a sintering raw material. The highest sintering temperature was set to 1450° C., and the holding time at the highest sintering temperature was set to 5 hours. Then, it was held at 1350° C. for 1 hour while cooling down. The sintered body obtained in this way has a sintered body density of 7.070 g / cm 3 , the bending strength is 115MPa, the volume resistivity is 0.110mΩ·cm, the average grain size is 3.43μm, the area ratio of the tin oxide-rich phase is 0.45%, the probability of the existence of the triple point of the tin oxide phase is 98%, and the pore area ratio is 0.08%.

[0114] Using this sintered body to make a target, the DC power density is 2.3W / cm 2 , The gas pressure is 0.6Pa, the sputtering gas is argon (Ar), and the gas flow rate is 300 sccm, and the sputtering is carried out continuously for 35 hours. As a ...

Embodiment 2

[0118] Use SnO whose ratio is adjusted so that Sn / (In+Sn) is 2.8% in atomic ratio 2 Powder and In 2 o 3 The powder was sintered in an oxygen atmosphere as a sintering raw material. The highest sintering temperature was set to 1450° C., and the holding time at the highest sintering temperature was set to 10 hours. Then, it was held at 1330° C. for 1 hour while cooling down. The sintered body obtained in this way has a sintered body density of 7.100 g / cm 3 , the bending strength is 120MPa, the volume resistivity is 0.116mΩ·cm, the average grain size is 3.54μm, the area ratio of the tin oxide-rich phase is 0.39%, the probability of triple point existence of the tin oxide phase is 99%, and the pore area ratio is 0.07%.

[0119] Using this sintered body to make a target, the DC power density is 2.3W / cm 2 , The gas pressure is 0.6Pa, the sputtering gas is argon (Ar), and the gas flow rate is 300sccm, and the sputtering is carried out continuously for 35 hours. As a result, the...

Embodiment 3

[0130] Use SnO whose ratio is adjusted so that Sn / (In+Sn) is 2.8% in atomic ratio 2 Powder and In 2 o 3 The powder was sintered in an oxygen atmosphere as a sintering raw material. The highest sintering temperature was set to 1450° C., and the holding time at the highest sintering temperature was set to 15 hours. Then, it was held at 1370° C. for 1 hour while cooling down. The sintered body obtained in this way has a sintered body density of 7.105 g / cm 3 , the bending strength is 121MPa, the volume resistivity is 0.124mΩ·cm, the average grain size is 3.66μm, the area ratio of the tin oxide-rich phase is 0.35%, the probability of the existence of triple points of the tin oxide phase is 99%, and the pore area ratio is 0.05%.

[0131] Using this sintered body to make a target, the DC power density is 2.3W / cm 2 , The gas pressure is 0.6Pa, the sputtering gas is argon (Ar), and the gas flow rate is 300 sccm, and the sputtering is carried out continuously for 35 hours. As a re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com