A kind of clay stabilizer for slick water fracturing fluid and preparation method thereof

A clay stabilizer, a technology for hydraulic fracturing, applied in chemical instruments and methods, drilling compositions, organic chemistry, etc., can solve problems such as increasing environmental risks, pollution, etc. Stabilization features outstanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

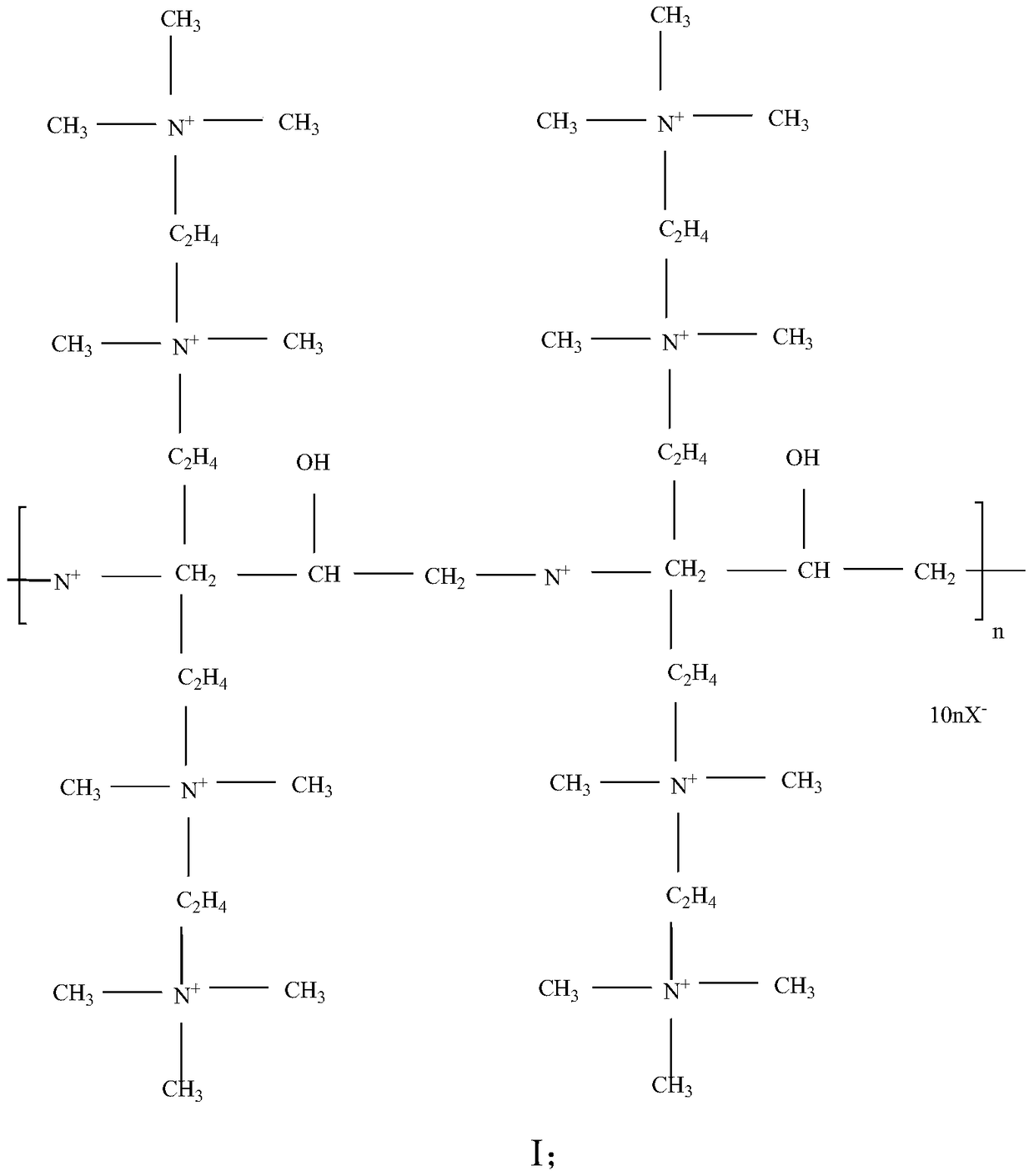

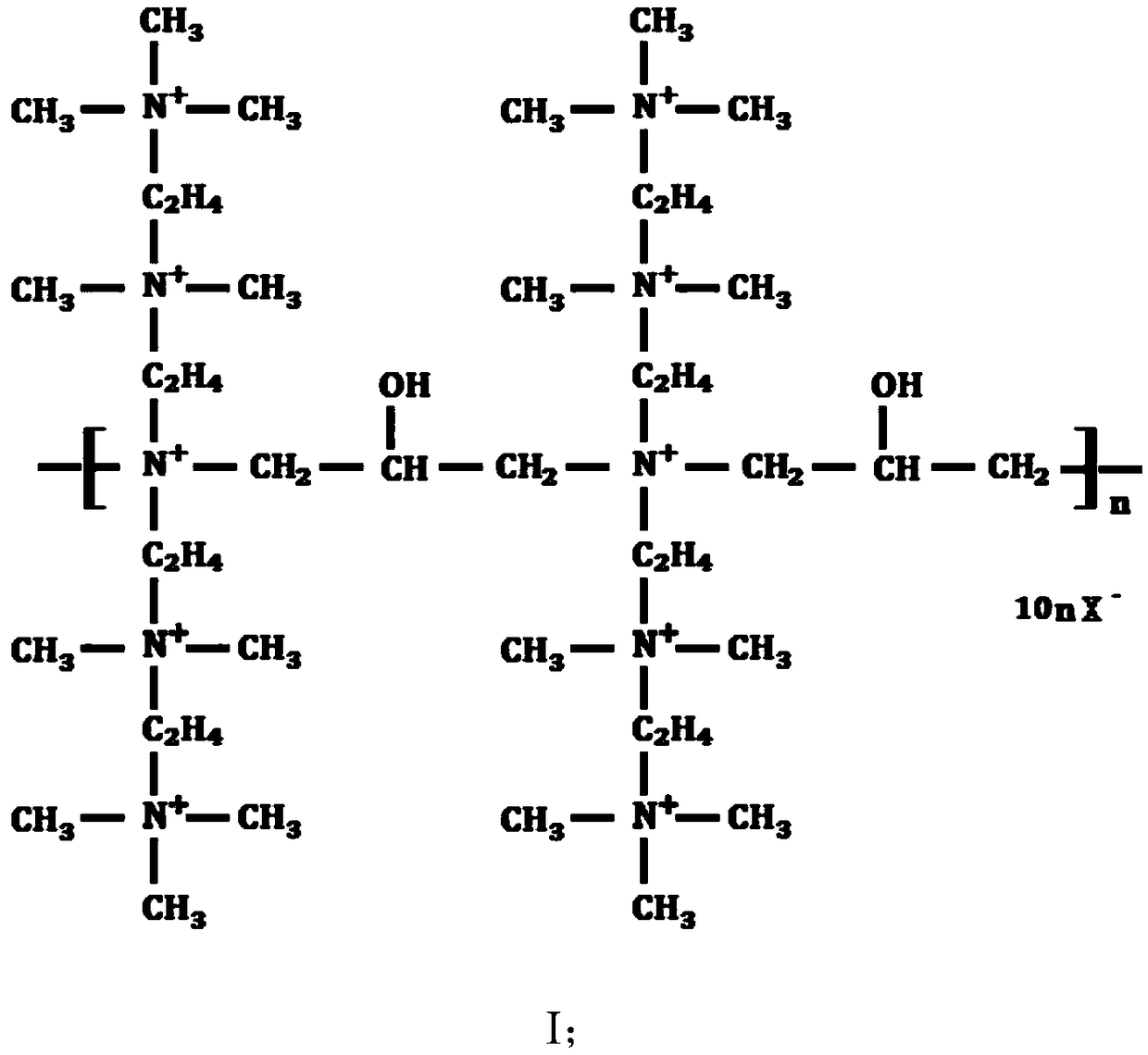

Image

Examples

Embodiment 1

[0024] Add 1,1,7,7-tetramethyldiethylenetriamine, 1-chloro-2,3-propylene oxide and 2-chloroethyltrimethylammonium chloride in a molar ratio of 1:1:2 In the solvent ethanol, the mass ratio of the reactant to the solvent is 1:3 to obtain a mixture; nitrogen is passed into the above mixture to remove the oxygen in the system; then the temperature is raised to 70°C; potassium persulfate / sodium sulfite is added as an initiator to initiate The mass ratio of the consumption of agent and reactant is 0.005:1; Continue to react for 5 hours, add hydroquinone as polymerization inhibitor to terminate reaction, the mass ratio of the addition of polymerization inhibitor and reactant is 0.005:1, obtain clay stabilizer.

Embodiment 2

[0026] Add 1,1,7,7-tetramethyldiethylenetriamine, 1-chloro-2,3-propylene oxide and 2-chloroethyltrimethylammonium chloride in a molar ratio of 1:2:1 In the solvent isopropanol, the mass ratio of the reactant to the solvent is 1:3 to obtain a mixture; nitrogen is introduced into the above mixture to remove the oxygen in the system; then the temperature is raised to 70°C; potassium persulfate / sodium sulfite is added as an initiator , the mass ratio of the consumption of initiator and reactant is 0.005:1; Continue to react for 5 hours, add hydroquinone as polymerization inhibitor to terminate reaction, the addition of polymerization inhibitor and the mass ratio of reactant are 0.005:1, Get a clay stabilizer.

Embodiment 3

[0028] Add 1,1,7,7-tetramethyldiethylenetriamine, 1-chloro-2,3-propylene oxide and 2-chloroethyltrimethylammonium chloride at a molar ratio of 1:3:0.5 In the solvent butanol, the mass ratio of the reactant to the solvent is 1:1 to obtain a mixture; nitrogen is passed into the above mixture to remove the oxygen in the system; then the temperature is raised to 90°C; hydrogen peroxide / ascorbic acid is added as an initiator, The mass ratio of the amount of the initiator to the reactant is 0.0010:1; the reaction is continued for 10 hours, and p-tert-butylcatechol is added as a polymerization inhibitor to terminate the reaction, and the mass ratio of the amount of the inhibitor to the reactant is 0.002:1 , to obtain a clay stabilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com