Polyacrylic acid spinning sizing agent

A technology of textile pulp and polyacrylate emulsion, applied in the direction of wear-resistant fibers, etc., can solve the problems of hygroscopicity, high re-viscosity, poor fluidity, inconvenient use, etc., and achieve good extensibility, good fluidity, and low viscosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A kind of textile slurry, described textile slurry is prepared by following raw material by weight:

[0044]

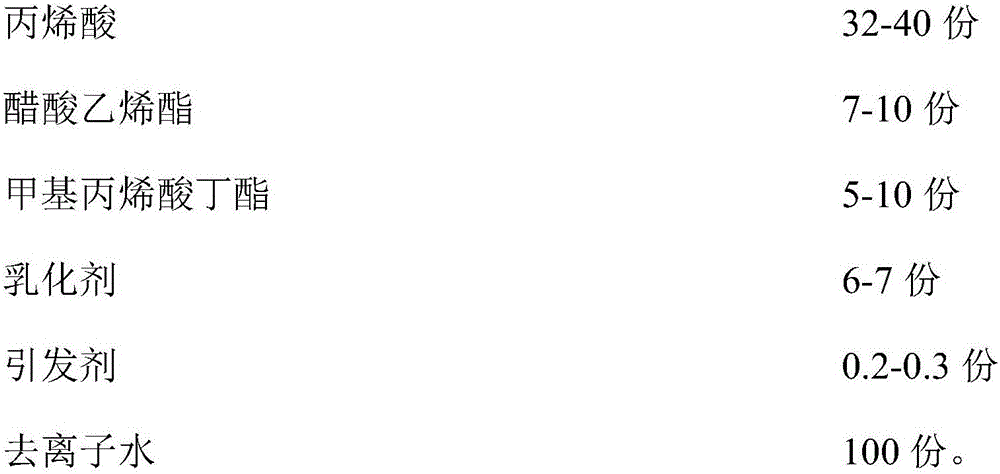

[0045] Wherein, the polyacrylate emulsion is prepared from the following raw materials in parts by weight:

[0046]

[0047] Described emulsifier is sodium lauryl sulfate.

[0048] The initiator is ammonium persulfate.

[0049] The defoamer is simethicone.

[0050] The preparation method of described polyacrylic acid textile size comprises the steps:

[0051] (1) Mix the polyacrylic acid, vinyl acetate, butyl methacrylate, emulsifier, initiator and deionized water in the formula, and react at 50°C to obtain a polyacrylate emulsion;

[0052] (2) Mix the starch, hydroxyethyl cellulose and deionized water in the formula amount uniformly at 30°C to obtain the first solution;

[0053] (3) Mix the polyacrylate emulsion, the first solution, and the defoamer, heat it to 45° C., and keep it warm for 10 minutes to obtain the polypropionic acid textile slurry. ...

Embodiment 2

[0055] A kind of textile slurry, described textile slurry is prepared by following raw material by weight:

[0056]

[0057] Wherein, the polyacrylate emulsion is prepared from the following raw materials in parts by weight:

[0058]

[0059] The emulsifier is OP-10.

[0060] The initiator is ammonium persulfate.

[0061] The defoamer is simethicone.

[0062] The preparation method of described polyacrylic acid textile size comprises the steps:

[0063] (1) Mix polyacrylic acid, vinyl acetate, butyl methacrylate, emulsifier, initiator and deionized water in the formula, and react at 60°C to obtain a polyacrylate emulsion;

[0064] (2) Mix the starch, hydroxyethyl cellulose and deionized water in the formula amount uniformly at 35°C to obtain the first solution;

[0065] (3) Mix the polyacrylate emulsion, the first solution, and the defoamer, heat to 45° C., and keep it warm for 20 minutes to obtain the polypropionic acid textile slurry.

Embodiment 3

[0067] A kind of textile slurry, described textile slurry is prepared by following raw material by weight:

[0068]

[0069] Wherein, the polyacrylate emulsion is prepared from the following raw materials in parts by weight:

[0070]

[0071]

[0072] The emulsifier is sodium lauryl sulfate and OP-10 with a volume ratio of 1:1.

[0073] The initiator is ammonium persulfate.

[0074] The defoamer is simethicone.

[0075] The preparation method of described polyacrylic acid textile size comprises the steps:

[0076] (1) Mix polyacrylic acid, vinyl acetate, butyl methacrylate, emulsifier, initiator and deionized water in the formula amount, and react at 55°C to obtain a polyacrylate emulsion;

[0077] (2) Mix the starch, hydroxyethyl cellulose and deionized water in the formula amount uniformly at 30°C to obtain the first solution;

[0078] (3) Mix the polyacrylate emulsion, the first solution, and the defoamer, heat to 35° C., and keep it warm for 10 minutes to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com