A kind of preparation method and application of tomato extract for tobacco

A technology of tomatoes and extracts, which is applied in the field of preparation of tobacco spices, to achieve the effects of reducing irritation and residue, enriching smoke fragrance, and improving taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

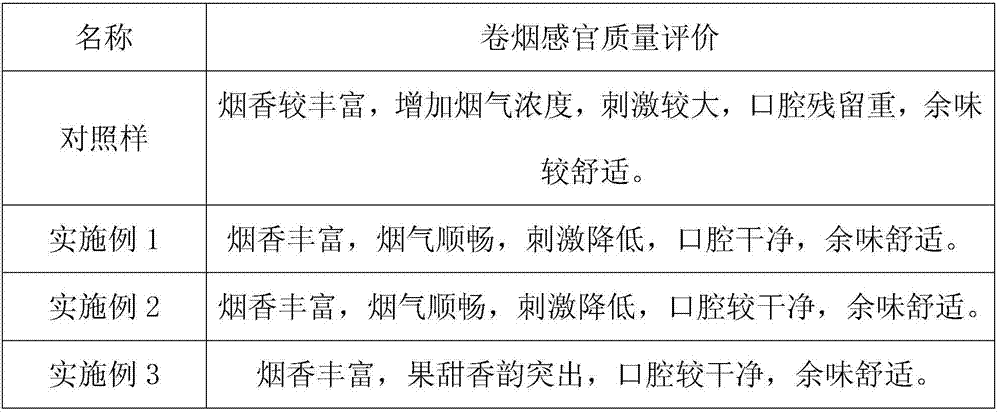

Examples

Embodiment 1

[0019] (1) Tomatoes are preferred, cut into 4mm thick and dry, put in a 150°C oven for 15 minutes, and dry in the air for later use;

[0020] (2) Take dried tomatoes, add 5 times the weight of water, and reflux extraction at 95° C. for 1.5 hours to obtain tomato extract;

[0021] (3) Use pectinase, compound plant hydrolytic cellulase and neutral protease to enzymatically hydrolyze the tomato extract, the compounding ratio is 1:1:0.5, and the dosage is 10g / L. The initial condition is pH 5, and the treatment temperature is 40 ℃, enzymatic hydrolysis time 10min;

[0022] (4) After the enzyme treatment, the enzyme is then inactivated at high temperature, refluxed and extracted again at 100°C for 0.5h, and then statically settled for 2h;

[0023] (5) Collect the extract in step (4), filter it with 0.8 microns, concentrate the extract under reduced pressure, the concentration temperature is 50°C, the concentration pressure is 0.01 to 0.2 atmospheres, and the concentration is concen...

Embodiment 2

[0025] (1) Prefer tomato, cut into 5mm thick and dry, put into 150 ℃ oven for 15min, dry in the air for later use;

[0026] (2) Take dried tomatoes, add 10 times the weight of water, and reflux and extract at 100° C. for 1 hour to obtain a tomato extract;

[0027] (3) Use pectinase, compound plant hydrolytic cellulase and neutral protease to enzymatically hydrolyze the tomato extract, the compounding ratio is 1:1:0.5, and the dosage is 15g / L. The initial condition is pH 6, and the treatment temperature is 35 ℃, treatment time 13min;

[0028] (4) After the enzyme treatment, the enzyme is then inactivated at high temperature, and then reflux extraction at 100°C for 1 hour, and static sedimentation for 2 hours. After collecting the extract and filtering it with 0.8 microns, the extract is concentrated under reduced pressure at a concentration temperature of 60°C. The pressure is 0.01 to 0.2 atmospheres, and concentrated to a relative density of 1.18g / mL to obtain tomato extract....

Embodiment 3

[0030] (1) Prefer tomato, cut into 6mm thick and dry, put into 150 ℃ oven for 15min, dry in the air for later use;

[0031] (2) Take dried tomatoes, add 15 times the weight of water, and reflux extraction at 90° C. for 1.5 hours to obtain tomato extract;

[0032] (3) Use pectinase, compound plant hydrolytic cellulase and neutral protease to enzymatically hydrolyze the tomato extract, the compounding ratio is 1:1:0.5, the dosage is 20g / L, the initial condition is pH 7, and the treatment temperature 40℃, treatment time 15min;

[0033] (4) After enzymatic treatment, high-temperature enzymatic inactivation, reflux extraction at 100°C for 1 hour, sedimentation for 2 hours, collecting the extract and filtering it with 0.8 microns, then concentrating the extract under reduced pressure at a concentration temperature of 50°C and a concentration pressure of 0.01 ~0.2 atmospheric pressure, concentrated to a relative density of 1.23g / mL, to obtain tomato extract.

[0034] The tomato ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com