Method for preparing metal-organic framework UiO-66 series membranes and separating methanol/methyl tert-butyl ether mixture

A metal-organic framework, uio-66 technology, applied in the separation/purification of hydroxyl compounds, semi-permeable membrane separation, ether separation/purification, etc. Improved crystallinity and high permeation flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

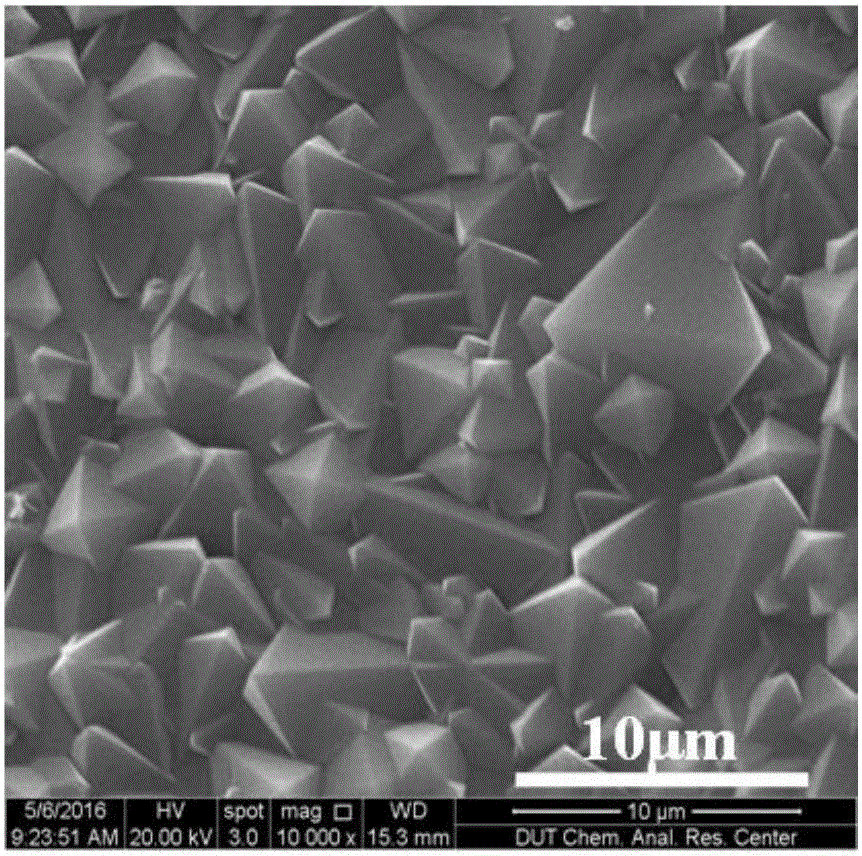

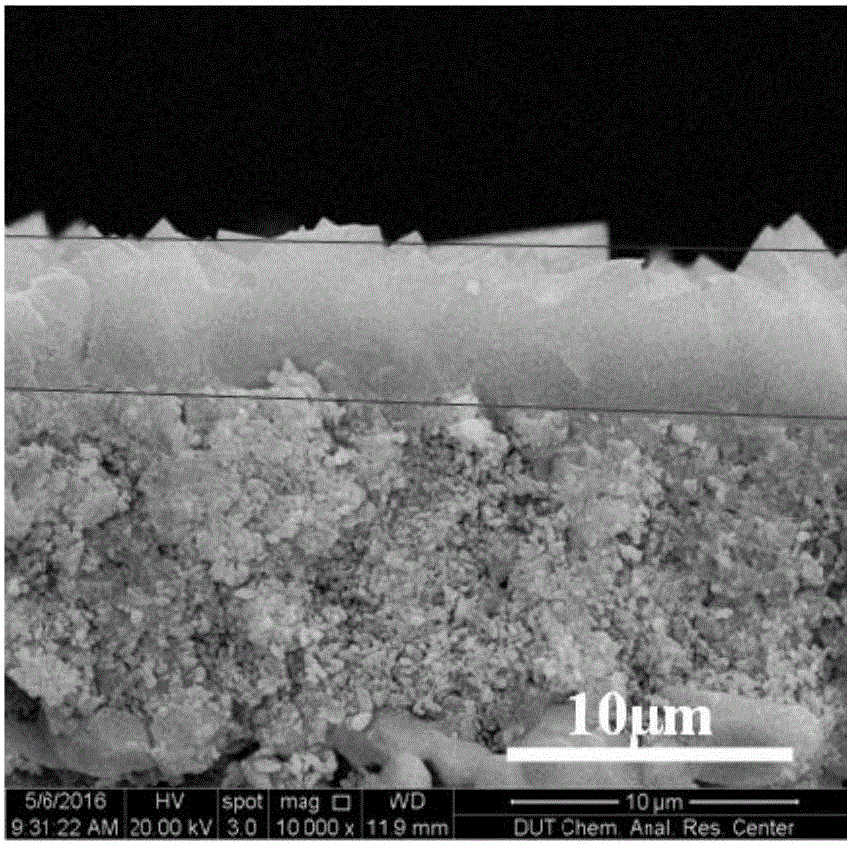

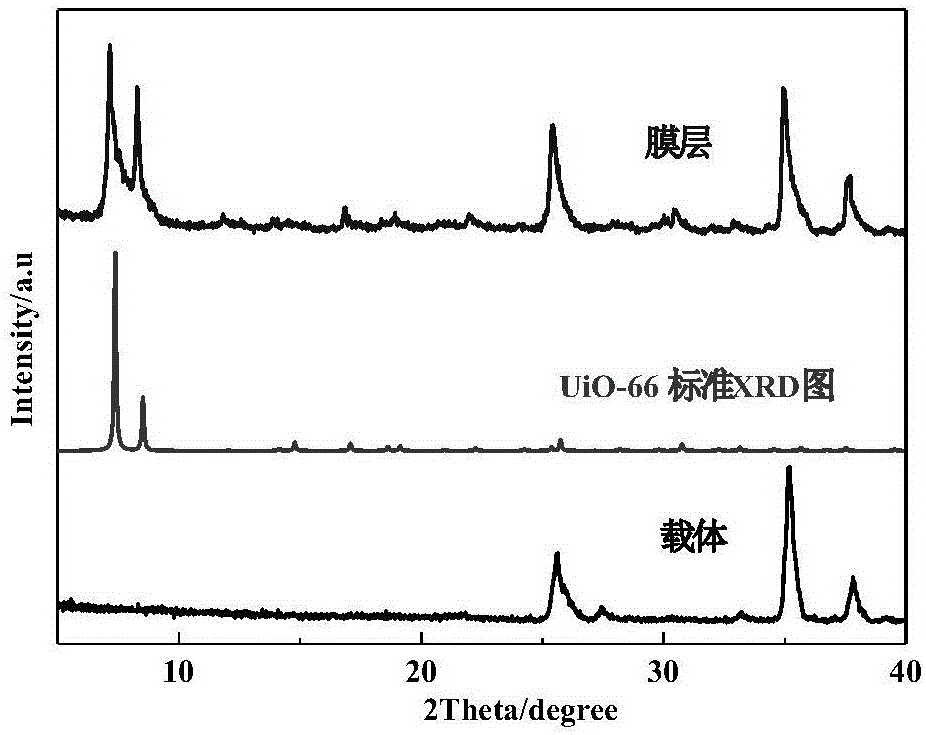

[0021] 1. Preparation of UiO-66 film

[0022] (1) Carrier pretreatment:

[0023] α-Al with a pore size of 0.2 μm 2 o 3 The ceramic tube carrier was vibrated in ultrasonic with acetone and ethanol, then rinsed with deionized water several times, vibrated ultrasonically, and dried at 100°C for later use.

[0024] (2) Preparation and implantation of UiO-66 seed crystals

[0025] Zirconium tetrachloride (ZrCl 4 ), terephthalic acid (H 2 BDC), glacial acetic acid (CH 3 COOH) and N,N-dimethylformamide (DMF) as raw materials, respectively weighed 0.0746g zirconium tetrachloride, 0.0532g terephthalic acid, 80ml N,N-dimethylformamide, 2.25ml glacial acetic acid , mixed and stirred for 30 minutes to prepare the UiO-66 seed crystal precursor solution, and injected into a stainless steel crystallization kettle with a polytetrafluoroethylene lining, sealed and placed in an oven at 120°C for 24 hours before taking it out to obtain a particle size of 100-150nm The pure UiO-66 seed cry...

Embodiment 2

[0031] 1. UiO-66-NH 2 Membrane preparation

[0032] (1) Carrier pretreatment:

[0033] α-Al with a pore size of 0.2 μm 2 o 3 The ceramic tube carrier was vibrated in ultrasonic with acetone and ethanol, then rinsed with deionized water several times, vibrated ultrasonically, and dried at 100°C for later use.

[0034] (2)UiO-66-NH 2 Seed preparation

[0035] Zirconium tetrachloride (ZrCl 4 ), aminoterephthalic acid (H 2 BDC-NH 2 ), glacial acetic acid (CH 3 COOH) and N,N-dimethylformamide (DMF) as raw materials, weigh 0.0746g zirconium tetrachloride, 0.0580g aminoterephthalic acid, 80ml N,N-dimethylformamide, 2.25ml ice Acetic acid, formulated UiO-66-NH 2 Seed precursor. Stir at room temperature for 30 minutes, pour into a stainless steel crystallization kettle lined with polytetrafluoroethylene, seal it and place it in an oven at 120°C, and take it out after 24 hours. Obtain pure UiO-66-NH with a particle size of 100-150nm 2 The seed crystal is prepared into an aq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com