A kind of preparation method of spherical cobalt blue material

A blue, spherical technology, applied in chemical instruments and methods, cobalt compounds, inorganic chemistry, etc., can solve the problems of scattering, not easy to deposit, etc., and achieve the effects of reducing wear, facilitating modulation and printing, and low friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

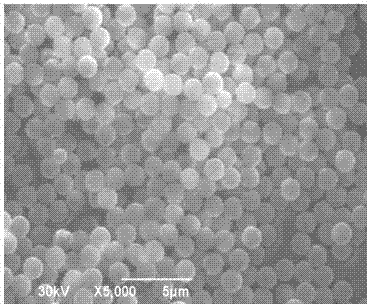

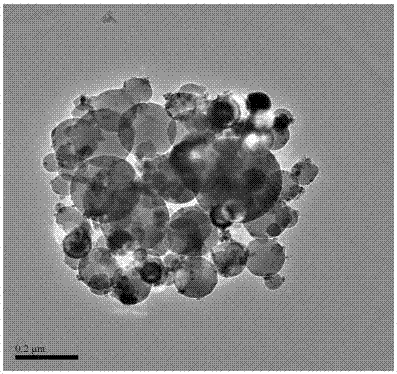

Image

Examples

preparation example Construction

[0029] The invention relates to a preparation method of spherical cobalt blue material, which is to prepare spherical cobalt blue material powder by combining three methods of W / O type microemulsion (or emulsion)-uniform precipitation-co-precipitation; Cobalt chloride hexahydrate, aluminum chloride solution) and precipitant (urea solution) are added to the oil phase liquid to form a W / O type microemulsion (or emulsion), and the water surrounded by the microemulsion (or emulsion) is heated by an oil bath A chemical reaction takes place in the nucleus to produce spherical precipitates. The uniform precipitation method in which urea is used as a precipitant can control the size, agglomeration and particle size distribution of the primary nanoparticles; the co-precipitation method in which cobalt chloride and aluminum chloride are simultaneously precipitated can control the uniformity of the composition and structure of the secondary particles. The precipitate is distilled, dried ...

Embodiment 1

[0036] (1) Dissolve cobalt chloride hexahydrate and aluminum chloride in deionized water, press Co. 2+ The concentration is 0.6mol / L, Al 3+ The concentration is 1.4mol / L to prepare a mixed solution;

[0037] (2) Select urea as the precipitant, dissolve the urea with deionized water, and prepare a solution with a concentration of 10 mol / L;

[0038] (3) Mix 3ml of the mixed solution described in (1) with 3ml of the solution described in (2) to prepare an aqueous mother liquor;

[0039] (4) Dissolve 0.8ml of Triton X-100 and 0.4ml of n-hexanol in 20ml of liquid paraffin and stir for 30min to form a uniform solution;

[0040] (5) adding the aqueous phase mother liquor described in (3) into the solution described in (4), and emulsified at 10000 rpm for 5 minutes after ultrasonic wave for 10 minutes to form a uniform powder-white emulsion;

[0041] (6) The emulsion described in (5) was placed in an oil bath for reaction and kept stirring at a speed of 600 rpm, the reaction temper...

Embodiment 2

[0044] (1) Dissolve cobalt chloride hexahydrate and aluminum chloride in deionized water, press Co. 2+ The concentration is 0.015mol / L, Al 3+ The concentration is 0.03mol / L to prepare a mixed solution;

[0045] (2) Select urea as the precipitant, dissolve the urea with deionized water, and prepare a solution with a concentration of 0.5mol / L;

[0046] (3) Mix 5ml of the mixed solution described in (1) with 5ml of the solution described in (2) to prepare an aqueous mother liquor;

[0047] (4) Dissolve 2ml of Triton X-100 and 1ml of n-hexanol in 20ml of liquid paraffin and stir for 30min to form a uniform solution;

[0048] (5) The aqueous phase mother liquor described in (3) was added to the solution described in (4) at a rate of 0.2 ml / min with a burette, and a magnetic stirrer was used for stirring at a speed of 600 rpm during the dropwise addition; the titration was completed. Then continue stirring at the above speed for 2h to form a powdery white emulsion

[0049] (6) T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com