Method for preparing ethyl nervonate by using acer-trunctum-bung oil as raw material

A technology of ethyl nervate and Yuanbaofeng, which is applied in fatty acid esterification, carboxylate preparation, chemical instruments and methods, etc., can solve the problem of many six-stage molecular distillation stages, unsuitable for technological production and low separation efficiency. and other problems, to achieve the effect of good separation effect, favorable for industrial production and small product denaturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) 1000g Ingot Maple Oil and 400ml of absolute ethanol and 40ml of sodium ethylate (20% sodium ethylate in ethanol) were subjected to a transesterification reaction at 75°C for 2 hours. After the reaction, unreacted ethanol was reclaimed. Stand still to remove glycerin, alkali and a small amount of ethanol, then wash with water until neutral, dry and dehydrate in vacuum to obtain Ingot Maple Oil Ethyl Ester;

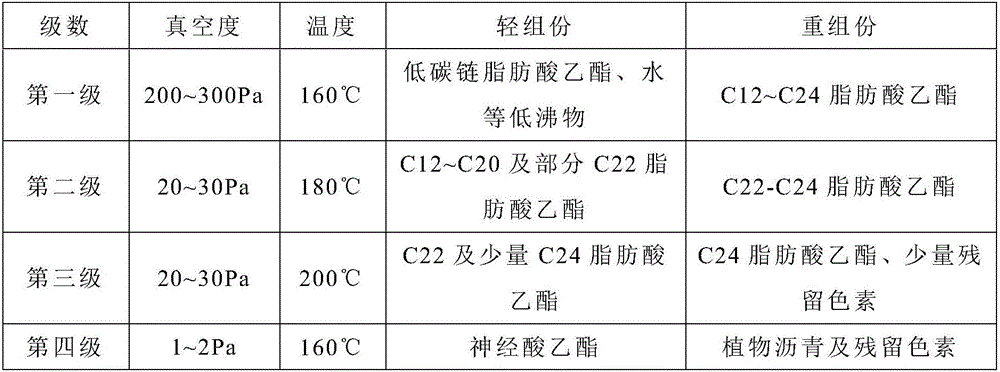

[0034] 2) the ingot maple oil ethyl ester in the step 1) is removed through the first-stage rectification to remove the first-stage light component, and obtain the first-stage heavy component;

[0035] 3) removing the second-stage light components from the first-stage heavy components in step 2) through second-stage rectification to obtain the second-stage heavy components;

[0036] 4) removing the third-level light component through the third-level rectification of the second-level heavy component in step 3), to obtain the third-level heavy component;

[0037] 5) ...

Embodiment 2

[0043] 1) Put 1000g of maple ingot oil, 600ml of absolute ethanol and 10g of sodium hydroxide at 80°C for 1 hour for transesterification. After the reaction, recover the unreacted ethanol and let it stand to remove glycerin, alkali and A small amount of ethanol, then washed with water until neutral, vacuum dried and dehydrated to obtain Ingot Maple Oil Ethyl Ester;

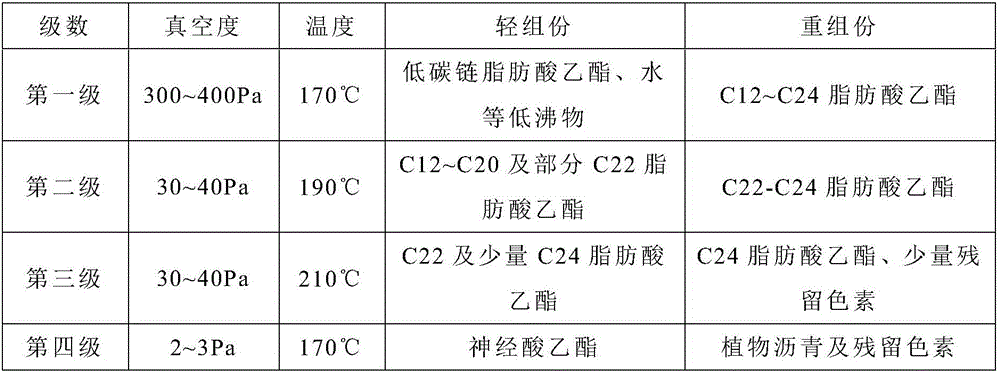

[0044] 2) the ingot maple oil ethyl ester in the step 1) is removed through the first-stage rectification to remove the first-stage light component, and obtain the first-stage heavy component;

[0045] 3) removing the second-stage light components from the first-stage heavy components in step 2) through second-stage rectification to obtain the second-stage heavy components;

[0046] 4) removing the third-level light component through the third-level rectification of the second-level heavy component in step 3), to obtain the third-level heavy component;

[0047] 5) The third stage heavy component in step 4) is sep...

Embodiment 3

[0053] 1) Put 1000g of maple ingot oil, 500ml of absolute ethanol and 8g of potassium hydroxide at 70°C for 1.5 hours for transesterification. After the reaction, recover the unreacted ethanol and let it stand to remove glycerin, alkali and A small amount of ethanol, then washed with water until neutral, vacuum dried and dehydrated to obtain Ingot Maple Oil Ethyl Ester;

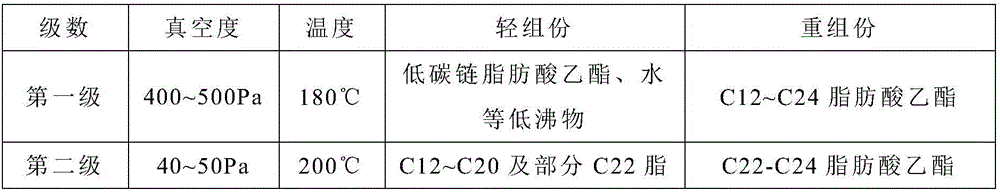

[0054] 2) the ingot maple oil ethyl ester in the step 1) is removed through the first-stage rectification to remove the first-stage light component, and obtain the first-stage heavy component;

[0055] 3) removing the second-stage light components from the first-stage heavy components in step 2) through second-stage rectification to obtain the second-stage heavy components;

[0056] 4) removing the third-level light component through the third-level rectification of the second-level heavy component in step 3), to obtain the third-level heavy component;

[0057] 5) The third stage heavy component in step 4) i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com