A method of self-assembling nanofibers using small molecular weight sodium alginate

A technology of sodium alginate and small molecular weight, applied in the direction of nanotechnology, alginate artificial filament, etc., can solve the problems of high cost of electrospinning equipment, difficult control of process parameters, and complicated preparation process of spinning solution. Achieve the effects of long-term preservation, simple instruments/equipment, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

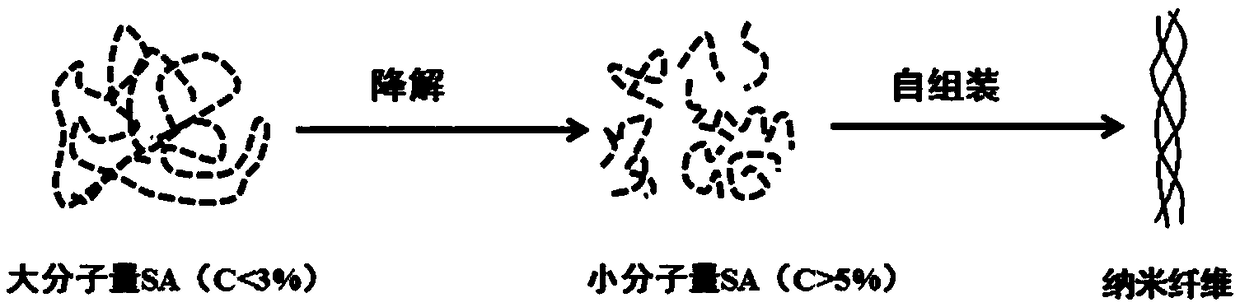

[0044] Preparation methods include as figure 1 Three steps are shown:

[0045] The first step, the preparation of the sodium alginate of small molecular weight:

[0046] Proportionally, high molecular weight sodium alginate (weight average molecular weight is 313kDa) was added into deionized water, swelled and dissolved by stirring to obtain a sodium alginate solution A with a concentration of 1.5% by mass;

[0047] Then, add hydrogen peroxide to obtain a mixed solution, the mass fraction of hydrogen peroxide in the mixed solution is 1.5%;

[0048] Heat the mixed solution to 65°C in a water bath, and stir for 12 hours;

[0049] Then, according to the volume ratio of the mixed solution and absolute ethanol being 1:2, add absolute ethanol to the mixed solution, precipitate and centrifuge to obtain a solid with small molecular weight sodium alginate as the main component;

[0050] The resulting solid was dissolved in deionized water, followed by dialysis and freeze-drying to o...

Embodiment 2

[0056] Preparation methods include as figure 1 Three steps are shown:

[0057] The first step, the preparation of the sodium alginate of small molecular weight:

[0058] In proportion, sodium alginate with a large molecular weight (weight-average molecular weight of 586kDa) was added to deionized water, swelled and dissolved by stirring, to obtain a sodium alginate solution A with a concentration of 1.5% by mass;

[0059] Then, add hydrogen peroxide to obtain a mixed solution, the mass fraction of hydrogen peroxide in the mixed solution is 1.5%;

[0060] Heat the mixed solution to 65°C in a water bath, and stir for 15 hours;

[0061] Then, according to the volume ratio of the mixed solution and absolute ethanol being 1:2, add absolute ethanol to the mixed solution, precipitate and centrifuge to obtain a solid with small molecular weight sodium alginate as the main component;

[0062] The resulting solid was dissolved in deionized water, followed by dialysis and freeze-dryin...

Embodiment 3

[0070] Preparation methods include as figure 1 Three steps are shown:

[0071] The first step, the preparation of the sodium alginate of small molecular weight:

[0072] In proportion, sodium alginate with a large molecular weight (weight-average molecular weight of 425kDa) was added to deionized water, swelled and dissolved by stirring to obtain a sodium alginate solution A with a concentration of 1.5% by mass;

[0073] Then, add hydrogen peroxide to obtain a mixed solution, the mass fraction of hydrogen peroxide in the mixed solution is 1.5%;

[0074] Heat the mixed solution to 65°C in a water bath, and stir for 5 hours;

[0075] Then, according to the volume ratio of the mixed solution and absolute ethanol being 1:2, add absolute ethanol to the mixed solution, precipitate and centrifuge to obtain a solid with small molecular weight sodium alginate as the main component;

[0076] The resulting solid was dissolved in deionized water, followed by dialysis and freeze-drying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com