Preparation method of multilevel porous structure manganous-manganic oxide/carbon nanosheet negative electrode material for lithium-ion battery

A technology of trimanganese tetraoxide and lithium-ion batteries, which is applied in the field of electrochemistry, can solve the problems of reducing the porosity of composite materials, uncontrollable reaction process, poor repeatability, etc., and achieves inhibition of dissolution loss, excellent high-rate discharge performance, and increased conductivity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing a negative electrode material for a lithium-ion battery with a multi-level porous structure manganese tetraoxide / carbon nanosheet, the steps are as follows:

[0029] 6mmol of Mn(CH 3 COO) 2 4H 2 O and 150ml ethylene glycol reagent were put into the reaction kettle, and after vigorous stirring, the Mn(CH 3 COO) 2 4H 2 O is completely dissolved. Then the obtained solution was transferred to a reflux device, refluxed at 170° C. for 2 hours, and naturally cooled to obtain a white manganese-based complex precursor, which was washed, centrifuged, and vacuum-dried. Put the obtained manganese-based complex into a tube furnace with nitrogen or argon, and thermally decompose it at 400-600°C for 0.5-6h, with a heating rate of 2-10°C / min, to obtain nanosheet-shaped porous Mn 3 o 4 / C composite anode material.

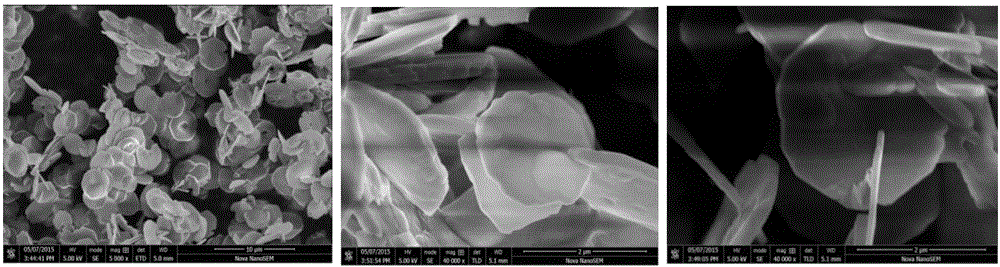

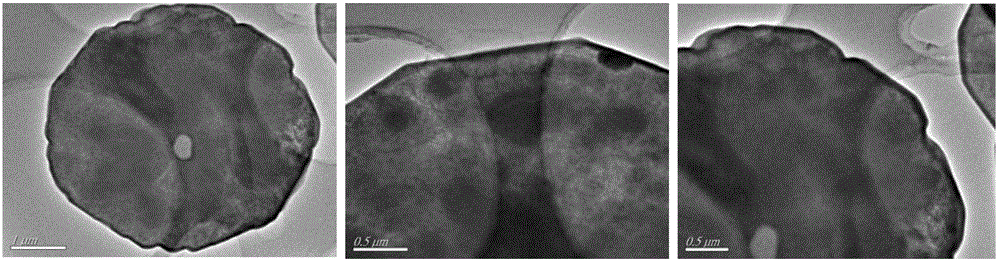

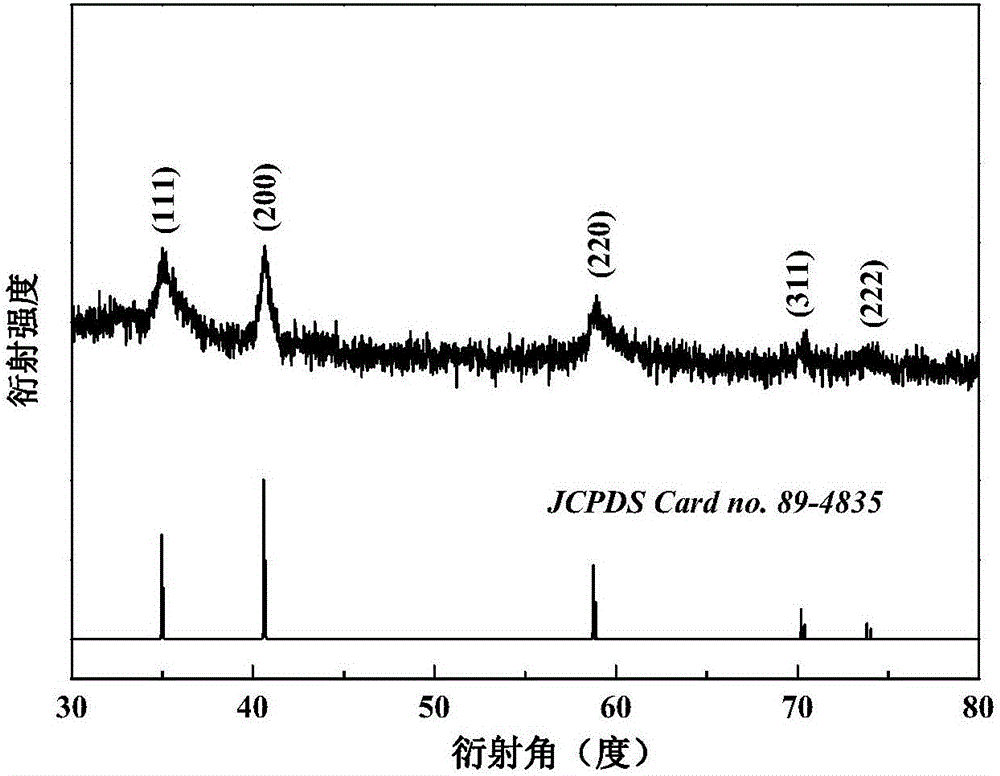

[0030] figure 1 and figure 2 The scanning electron microscope and transmission electron microscope images of the manganese-ethylene glycol ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com