Compound photocatalytic material and preparation method and application thereof

A technology of composite photocatalysis and carbon materials, applied in the field of photocatalysis materials, can solve problems such as unsuitable for large-scale industrial production, difficult to control material structure, environmental hazards of strong acid and strong alkali, etc., to promote transmission and transfer, low equipment requirements, Artisanal and easy-to-handle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

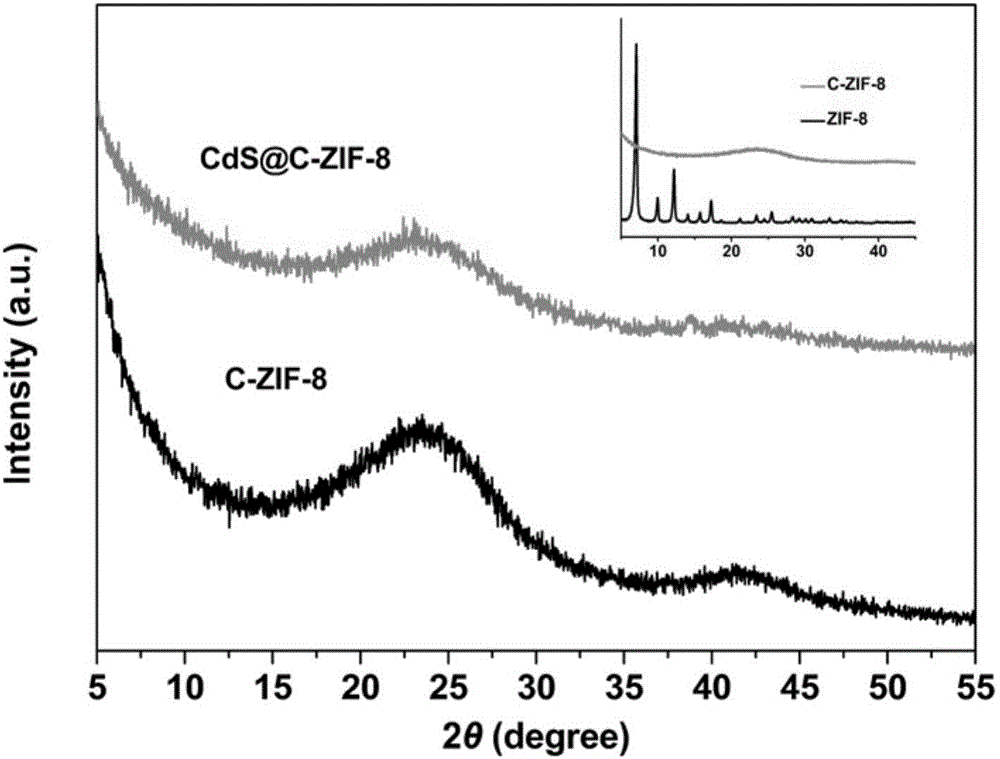

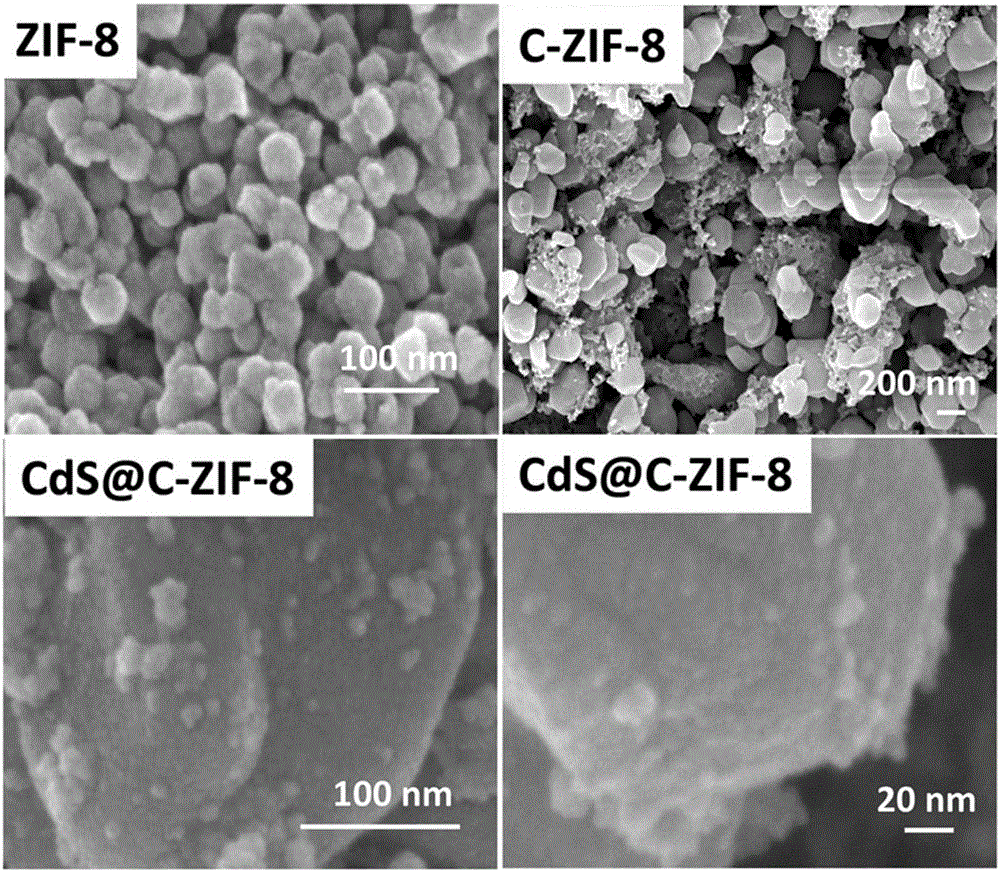

[0031] (1) Weigh 9mmol of zinc nitrate and 70mmol of dimethylimidazole and dissolve in 200mL of methanol solution, stir to form a homogeneous solution, then vigorously stir at room temperature for 1h, and the formed solid is centrifuged and washed with methanol, then dried in vacuum at 50°C One night, ZIF-8 white powder was obtained;

[0032] (2) the ZIF-8 powder that step (1) obtains is put into tube furnace, under N 2 In the atmosphere, the temperature was raised to 700 degrees at a rate of 5°C / min, and kept at this temperature for 2 hours, and then cooled down to room temperature naturally, and a mixture of metal / metal oxide and carbonaceous material was obtained;

[0033] (3) Add 30mL of 1mol / L hydrochloric acid solution to the 2.02g mixture obtained in step (2), stir at room temperature for 12h, rinse with water for 3 times, and dry naturally to obtain the C-ZIF-8 carbon material;

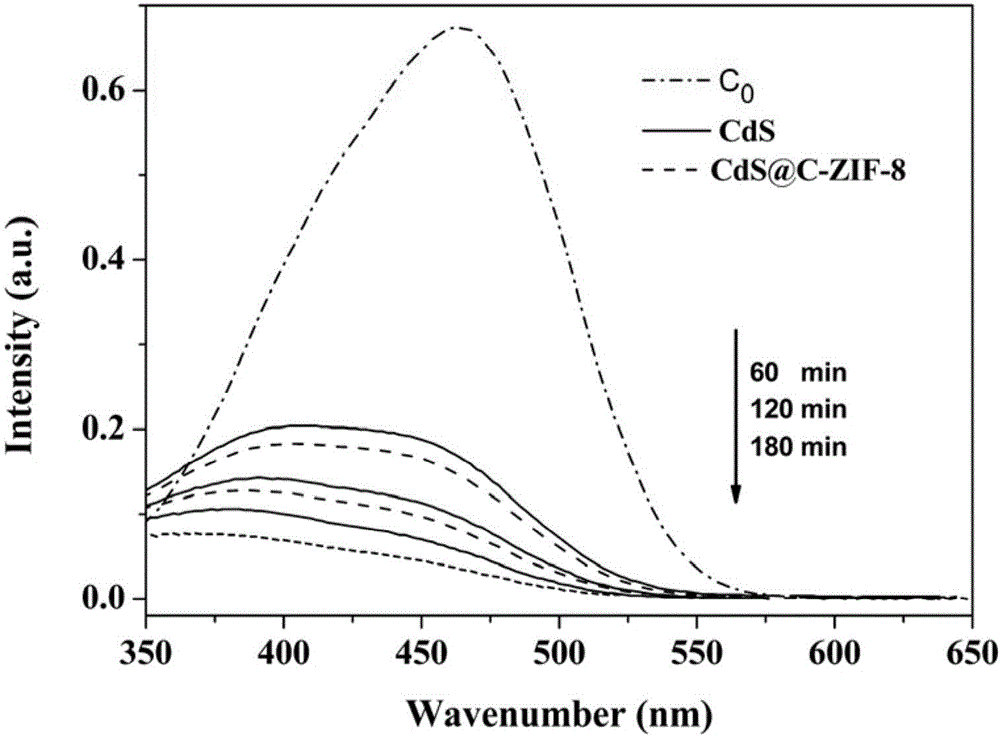

[0034] (4) Ultrasonically disperse 0.15g of the carbon material obtained in step (3) in 1...

Embodiment 2

[0036] (1) Weigh 9mmol of zinc nitrate and 60mmol of dimethylimidazole and dissolve in 200mL of N,N-dimethylformamide solution, stir to form a homogeneous solution, then vigorously stir at room temperature for 12h, and the formed solid is centrifuged and methanol After washing, vacuum-dry at 50°C overnight to obtain ZIF-8 white powder;

[0037] (2) the ZIF-8 powder that step (1) obtains is put into tube furnace, under N 2 In the atmosphere, the temperature was raised to 900 degrees at a rate of 5°C / min, and kept at this temperature for 4h, and then cooled down to room temperature naturally, and a mixture of metal / metal oxide and carbonaceous material was obtained;

[0038] (3) Add 30 mL of 1 mol / L hydrochloric acid solution to the 1.85 g mixture obtained in step (2), stir at room temperature for 24 h, then rinse with water for 3 times, and obtain C-ZIF-8 carbon material after drying;

[0039] (4) Ultrasonically disperse 0.1g of the carbon material obtained in step (3) in 100m...

Embodiment 3

[0041] (1) Weigh 10mmol of zinc nitrate and 80mmol of dimethylimidazole and dissolve them in 200mL of N,N-dimethylformamide solution, stir to form a homogeneous solution, then vigorously stir at room temperature for 24h, the formed solid is centrifuged and methanol After washing, vacuum-dry at 50°C overnight to obtain ZIF-8 white powder;

[0042] (2) the ZIF-8 powder that step (1) obtains is put into tube furnace, under N 2 In the atmosphere, the temperature was raised to 1100 degrees at a rate of 5°C / min, and kept at this temperature for 10h, and then naturally cooled down to room temperature, that is, a mixture of metal / metal oxide and carbonaceous material was obtained;

[0043](3) Add 30 mL of 1 mol / L hydrochloric acid solution to the 2.39 g mixture obtained in step (2), stir at room temperature for 8 hours, then rinse with water for 3 times, and obtain C-ZIF-8 carbon material after drying;

[0044] (4) Ultrasonically disperse 0.2g of the carbon material obtained in step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com