Hierarchically pored SAPO-11 molecular sieve and solid-phase synthesis method

A SAPO-11, solid-phase synthesis technology, applied in the field of material chemistry, can solve the problems of waste water and low yield, and achieve the effects of reducing waste water, increasing yield, and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a solid-phase synthesis method of multi-stage pore SAPO-11 molecular sieve. The solid-phase synthesis method includes: mixing and grinding a silicon source, an aluminum source, a mesoporous template, a microporous template, and a phosphorus source. The crystallization reaction is carried out at 140-220°C, and the product is centrifuged and dried, and then roasted to remove the template agent to obtain a hierarchical pore SAPO-11 molecular sieve.

[0033] As an example, the reaction time of the crystallization reaction is 12-72h. Preferably, the crystallization time of the crystallization reaction is 16-48h.

[0034] As an example, the reaction temperature range of the crystallization reaction is 160-200°C.

[0035] As an example, the silicon source is one or a mixture of white carbon black and sodium silicate. The aluminum source is one or a mixture of two or more of pseudo-boehmite, aluminum sulfate, and aluminum isopropoxide. The microporous templ...

Embodiment 2

[0041] This embodiment provides a solid-phase synthesis method of multi-porous SAPO-11 molecular sieve, which specifically includes: weighing 0.14 g white carbon black, 1.46 g pseudo-boehmite, 3.60 g di-n-propylamine phosphate, and 0.36 g sixteen Alkyl trimethyl ammonium bromide (CTAB), after mixing, grind for 10 minutes, put the obtained powder into a reactor, crystallize at 200 ℃ for 24 h, centrifuge the obtained product, and wash it at 80 ℃ Dry and roast at 600℃ for 6h to obtain the final product.

Embodiment 3

[0043] This embodiment provides a solid-phase synthesis method of multi-porous SAPO-11 molecular sieve, which specifically includes: weighing 0.14 g white carbon black, 1.46 g pseudo-boehmite, 3.14 g di-n-propylamine phosphate, and 0.36 g sixteen Alkyl trimethyl ammonium bromide (CTAB), mix and grind for 10 minutes, put the obtained powder into the reaction kettle, crystallize at 200℃ for 24h, centrifuge and wash the obtained product, dry it at 80℃ The final product was calcined at 600°C for 6 hours.

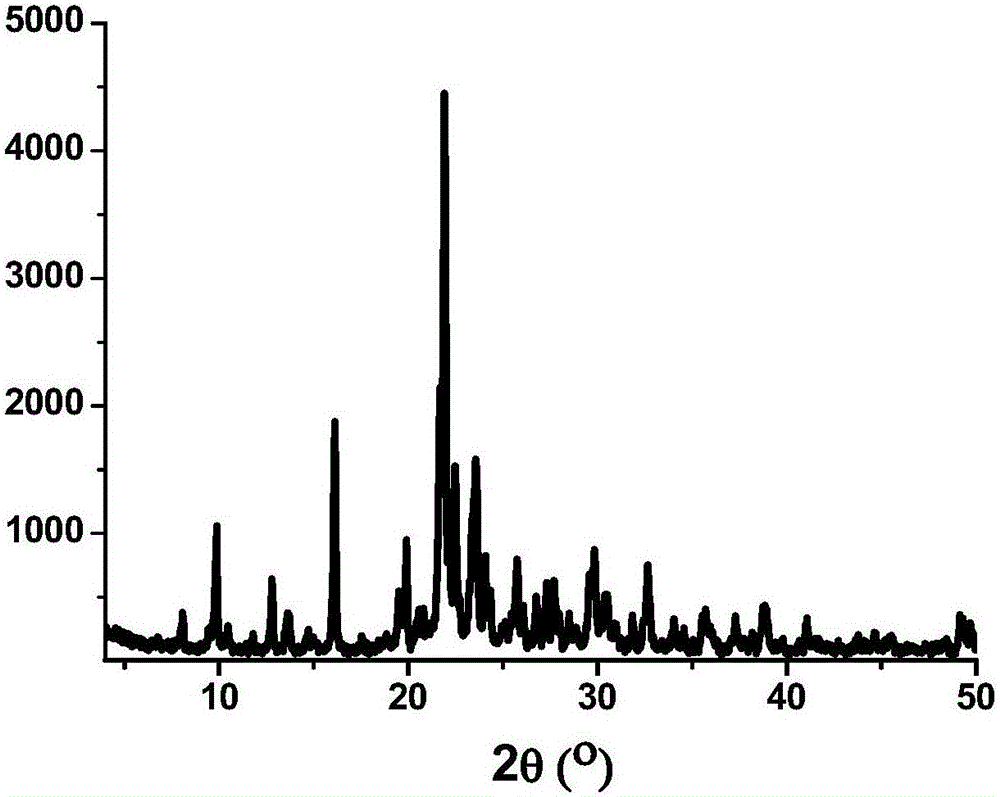

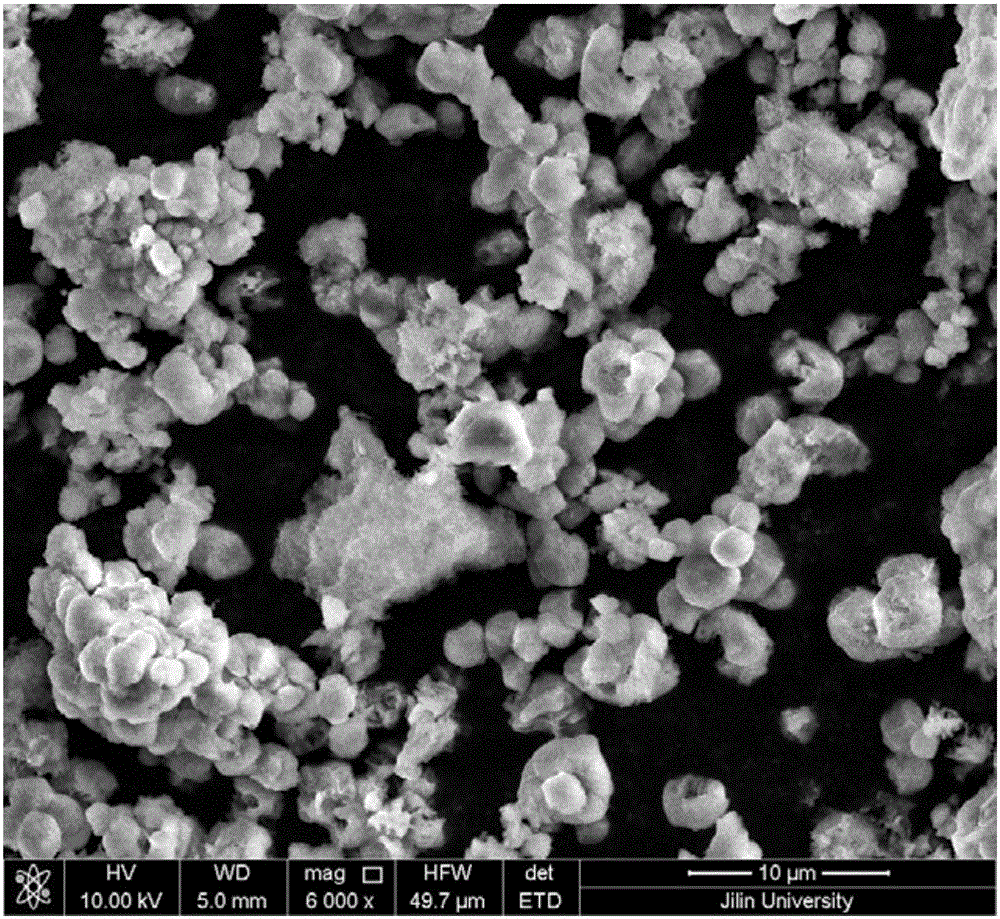

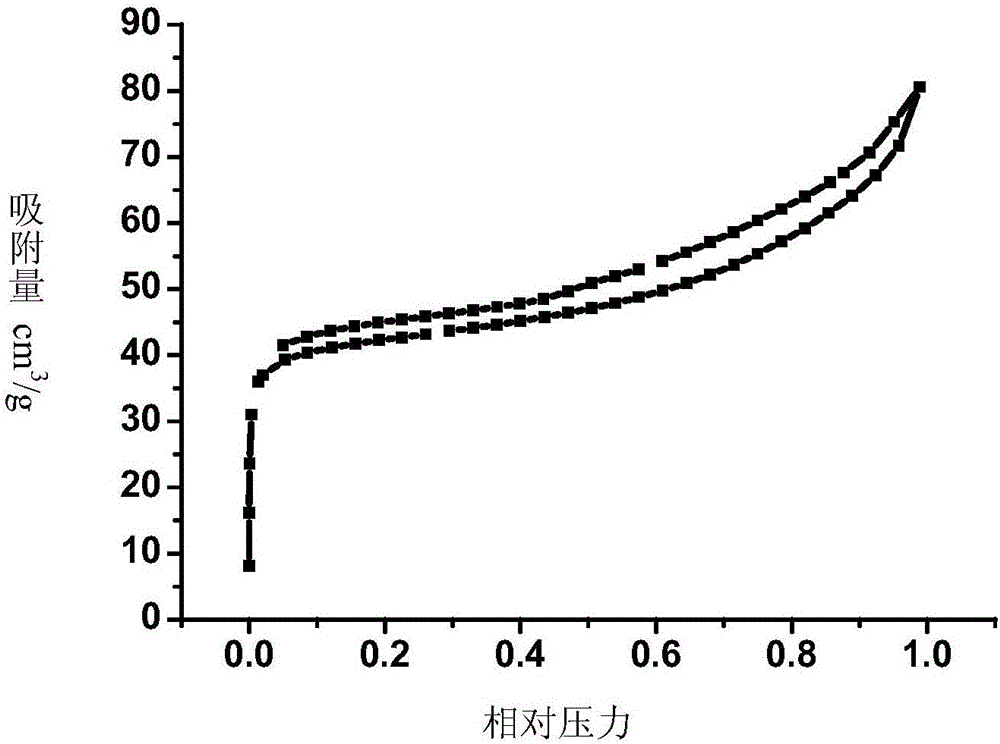

[0044] Figure 4 The XRD characterization results of the hierarchical pore SAPO-11 molecular sieve synthesized in this example are shown, and it can be seen that the product has a typical AEL structure with good crystallinity. Figure 5 It shows the scanning electron micrograph of the multi-porous SAPO-11 molecular sieve synthesized in this embodiment. It can be seen that the product is composed of balls and needle-like substances. Image 6 Shown is the nitrogen adsorption isotherm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com