Slow-release water-retention fertilizer and preparing method thereof

A slow-release and fertilizer technology, applied in the field of slow-release water-retaining fertilizer and its preparation, can solve the problems of high-concentration compound fertilizer nutrient loss, high labor consumption cost, insufficient medium and trace element content, etc., so as to alleviate crop growth obstacles and reduce moisture. Loss, stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1 A slow-release water-retaining fertilizer

[0037] In this embodiment, the slow-release water-retaining fertilizer is prepared from the following weight percentages of raw materials: calcium lignosulfonate 9%, polyacrylamide 3%, potassium humate 5%, molasses powder 15%, heptahydrate Zinc sulfate and borax 5%, thiamine 20%, calcium magnesium phosphate fertilizer 38%, potassium sulfate 5%.

[0038] The preparation method of the aforementioned slow-release water-retaining fertilizer includes the following steps:

[0039] 1). All raw materials are pre-crushed to make the fineness of raw materials above 80 mesh;

[0040] 2) Using double-screw blending equipment, spray an appropriate amount of water mist on the pre-crushed raw materials, mix them evenly for 15 minutes until the moisture content of the raw materials is ≦3-5%, and discharge;

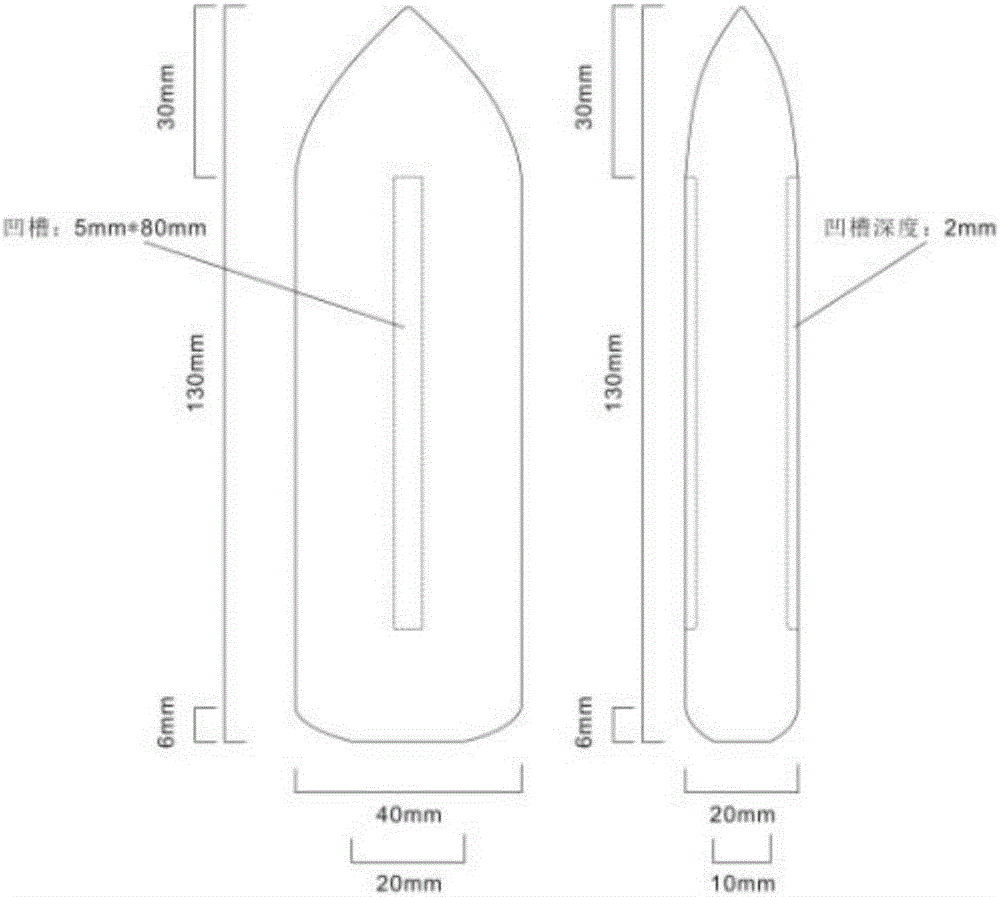

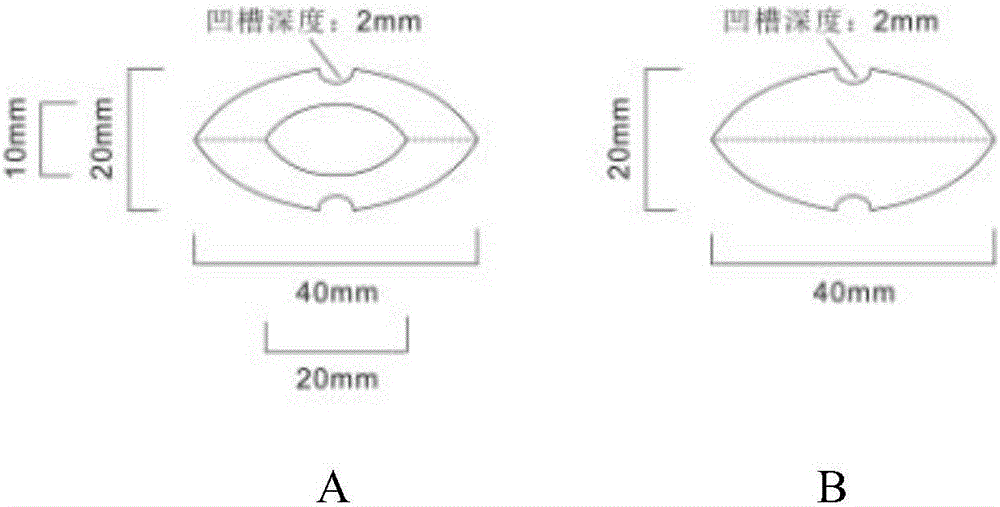

[0041] 3). Use screw conveying equipment to squeeze and convey the material to the forming ball press, use the special roller mold of t...

Embodiment 2

[0076] Example 2 A slow-release water-retaining fertilizer

[0077] In this embodiment, the slow-release water-retaining fertilizer is prepared from the following weight percentages of raw materials: calcium lignosulfonate 10%, polyacrylamide 4%, potassium humate 5%, molasses powder 15%, heptahydrate Zinc sulfate and borax 5%, thiamine 20%, calcium magnesium phosphate fertilizer 35%, potassium sulfate 6%.

[0078] The preparation method of the above-mentioned slow-release water-retaining fertilizer is the same as that of Example 1.

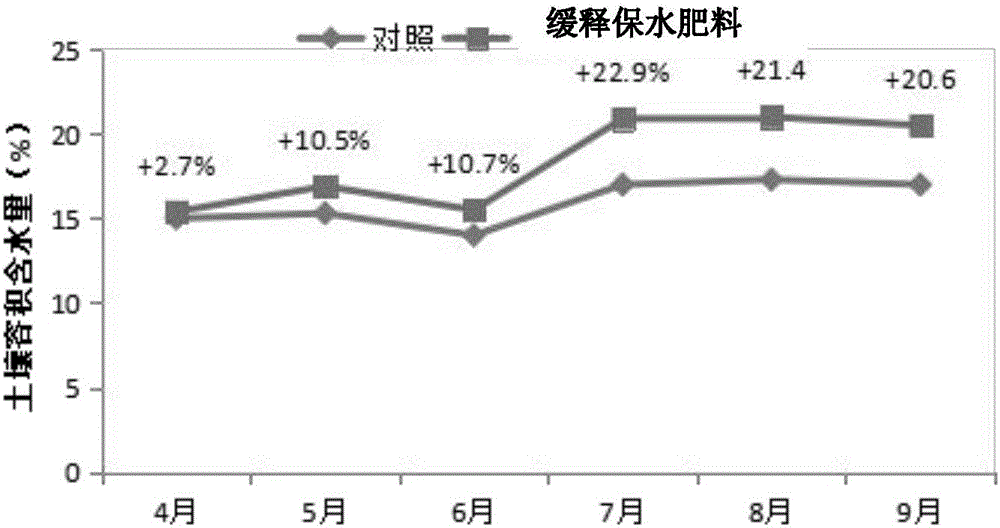

[0079] Test Example 2 Fertilization test of the slow-release water-retaining fertilizer of Example 2 on apples

[0080] 1. Test location and overview

[0081] Before apples sprouted in 2016, a nail fertilizer test was arranged at the Luochuan Apple Production Base in northern Shaanxi. Luochuan is a high-quality apple producing area in my country, with an altitude of 650m-1481m, sufficient sunshine and large temperature difference between day and night. T...

Embodiment 3

[0102] Example 3 A slow-release water-retaining fertilizer

[0103] In this embodiment, the raw materials of the slow-release water-retaining fertilizer are prepared: calcium lignosulfonate 9%, polyacrylamide 3%, potassium humate 5%, molasses powder 15%, zinc sulfate heptahydrate and borax 5%, thiamine 20%, calcium magnesium phosphate fertilizer 38%, potassium sulfate 5%.

[0104] The preparation method of the above-mentioned slow-release water-retaining fertilizer is the same as that of Example 1.

[0105] Test Example 3 Fertilization test of the slow-release water-retaining fertilizer of Example 3 on grapes

[0106] 1. Test material: the slow-release fertilizer of Example 3

[0107] 2. Test site: Hengnan County, Hunan.

[0108] 3. Test crop: grapes. The grape seedlings are planted for 3 years, and the planting density is 350 plants per mu. The planting management of the test site is the same every year, and the crops are growing.

[0109] 4. Test period: May

[0110] 5. Test method

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Altitude | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com