Refining method of propylene oxide

A technology of propylene oxide and refining method, applied in the direction of organic chemistry, etc., can solve the problem of low yield of propylene oxide, achieve the effect of reducing energy consumption, reducing losses, and simplifying the refining process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

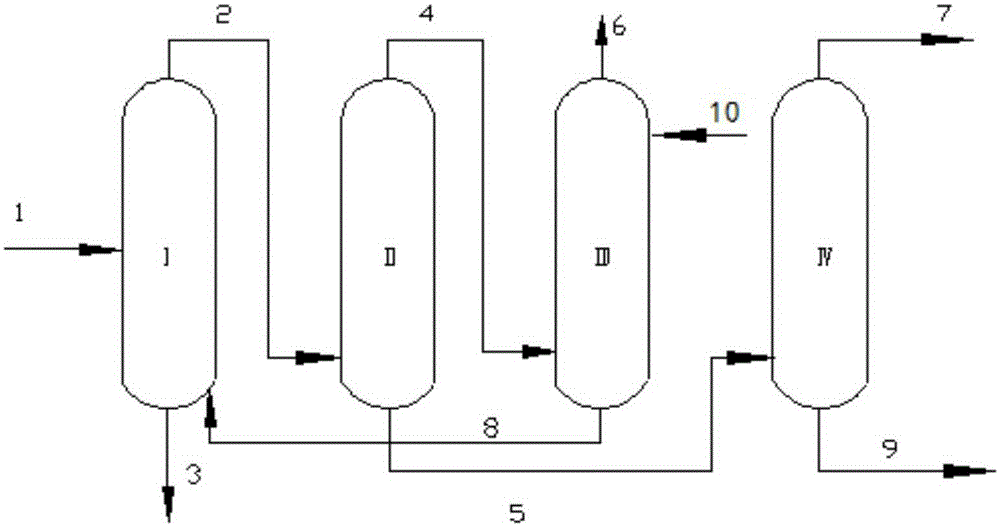

[0032] use figure 1 As shown in the process flow, the reaction product from the propylene oxide reactor enters the propylene separation tower, and the overhead product propylene, propane, propylene oxide, acetone, and aldehydes (containing acetaldehyde and propionaldehyde) are separated, and the bottom material contains ethylbenzene , cumene, α-methylstyrene, acetophenone, α, α-dimethylbenzyl alcohol, phenol and high-boiling point by-products; the top material of the propylene separation tower enters the propylene stripper, and the top of the stripper The gas contains propylene, propane, and a small amount of propylene oxide. This material enters the propylene oxide adsorption tower to contact with the absorbent to remove propylene oxide, and then returns to the reaction system for recycling after being compressed; the bottom material of the stripping tower contains epoxy Propane and acetone, this material enters the propylene oxide refining tower, the tower is filled with ads...

Embodiment 2

[0043] Same as [Example 1], except that the pressure of the propylene separation tower is 0.1 MPa, the number of theoretical plates is 30, the reflux ratio is 0.1, the temperature at the top of the tower is 35° C., and the temperature at the bottom of the tower is 70° C.

[0044] In terms of weight percentage, the top material of the propylene separation tower contains 65% propylene, 3% propane, 30% propylene oxide, 1.5% acetone, and 0.5% aldehydes; the bottom material contains 0.5% ethylbenzene, 35% isopropyl Benzene, 2% α-methylstyrene, 3.5% acetophenone, 55% α,α-dimethylbenzyl alcohol, 3% phenol, 1% high boiling point by-products.

[0045] The pressure of the propylene stripping tower is 0.2MPa, and the temperature of the bottom of the tower is 70°C.

[0046] In terms of weight percentage, the top material of the propylene stripping tower contains 98% propylene, 0.9% propane and 1.1% propylene oxide; the bottom material contains 96% propylene oxide, 2.5% acetone and 1.5% al...

Embodiment 3

[0052] Same as [Example 1], except that the pressure of the propylene separation tower is 0.2 MPa, the number of theoretical plates is 40, the reflux ratio is 0.4, the temperature at the top of the tower is 40° C., and the temperature at the bottom of the tower is 75° C.

[0053] In terms of weight percentage, the top material of the propylene separation tower contains 70% propylene, 0.5% propane, 28% propylene oxide, 1% acetone, and 0.5% aldehydes; the bottom material contains 0.2% ethylbenzene, 30% isopropyl Benzene, 2% α-methylstyrene, 1% acetophenone, 65% α,α-dimethylbenzyl alcohol, 0.8% phenol, 1% high boiling point by-products.

[0054] The pressure of the propylene stripping tower is 0.3MPa, and the temperature of the bottom of the tower is 75°C.

[0055] In terms of weight percentage, the top material of the propylene stripping tower contains 99% propylene, 0.9% propane and 0.1% propylene oxide; the bottom material of the tower contains 97% propylene oxide, 2% acetone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com