Method for preparing ursodesoxycholic acid on basis of chemical oxidation and enzyme catalysis combination technology

A technology of ursodeoxycholic acid and chemical oxidation is applied in the field of preparing ursodeoxycholic acid based on the combined technology of chemical oxidation and enzyme catalysis, and can solve the problems of lack of market competitiveness, high pollution, high energy consumption and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] The method for oxidizing chenodeoxycholic acid to generate intermediate 7-carbonyl-lithocholic acid by chemical oxidation method specifically comprises the following steps:

[0010] (1) Dissolve 6 g of chenodeoxycholic acid in 10 times the volume of acetone aqueous solution. The volume ratio of acetone to water is 2.7:1. After it is completely dissolved, add 4 g of NBS and stir at 30 ° C for 1.5 h. After the reaction is complete, add 40% NaHSO 3 , Diluted with 500ml of water to precipitate the product.

[0011] (2) Filter the reaction solution I, dry the product, and dry it to obtain white and loose 7-carbonyl-lithocholic acid powder I.

Embodiment 2

[0013] Content Analysis of Raw Material CDCA

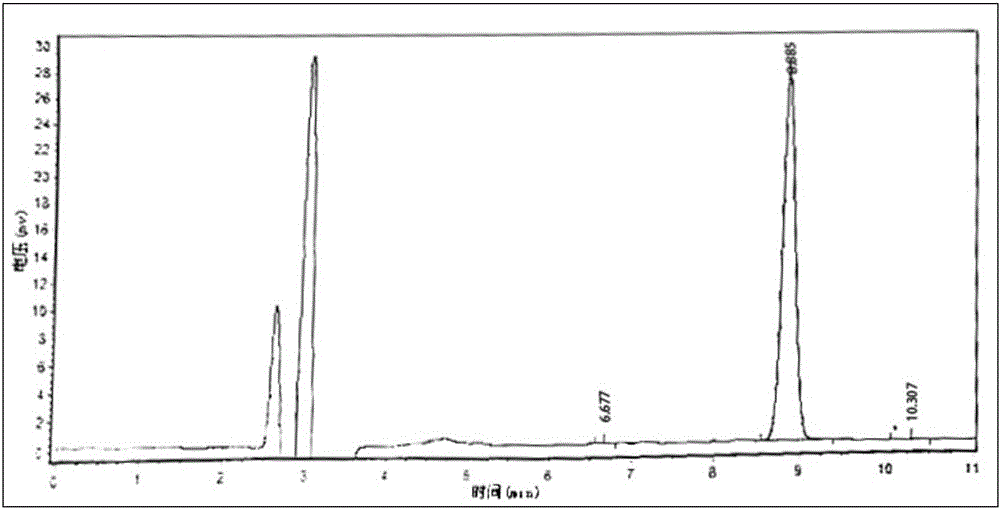

[0014] Take about 0.1g of powder I in a 50ml volumetric flask, add an appropriate amount of methanol, and dissolve it by ultrasonication (power 300W, frequency 25kHz) for 5 minutes, dilute to the mark with methanol, shake well, filter, take the filtrate, 10l, pass through high performance liquid chromatography instrument, using a vapor luminescence scattering detector, to record the chromatogram figure 1 , the chromatogram is analyzed, and the percentage content of CDCA is 98%. The control substance CDCA comes from the China Institute for the Control of Pharmaceutical and Biological Products.

Embodiment 3

[0016] Content Analysis of 7K-LCA in Powder Ⅰ after Reaction Liquid Ⅰ Treatment

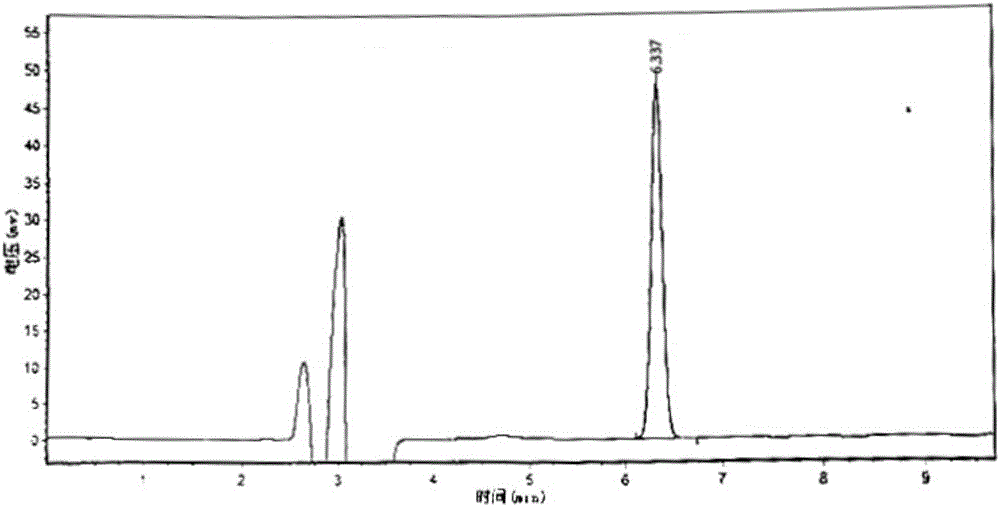

[0017] Take about 0.1g of powder I in a 50ml volumetric flask, add an appropriate amount of methanol, and dissolve it by ultrasonication (power 300W, frequency 25kHz) for 5 minutes, dilute to the mark with methanol, shake well, filter, take the filtrate, 10l, pass through high performance liquid chromatography instrument, using a vapor luminescence scattering detector, to record the chromatogram figure 2 , the chromatogram is analyzed, and the percentage content of 7K-LCA is 99%. The reference substance 7K-LCA was from the China Institute for the Control of Pharmaceutical and Biological Products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com