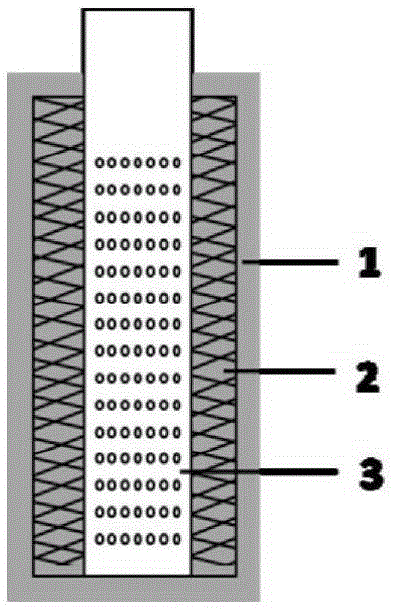

Porous electrode complex for carbon dioxide electrochemical reduction as well as preparation and application thereof

A porous electrode, carbon dioxide technology, applied in the direction of electrode shape/type, electrolysis process, electrolysis components, etc., can solve the problems of reducing the catalytic effect of the catalyst, changing the product distribution, poor stability, etc., to suppress the side reaction of hydrogen evolution and increase the retention. time, the effect of reducing the cost of electrode raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1. Gas diffusion substrate degreasing pretreatment: At room temperature, ultrasonically soak TGP-H-060 carbon paper with a length and width of 4cm and 5cm, a thickness of 0.2mm, and a porosity of 78% in acetone for 20 minutes, and then Wash with absolute ethanol, soak in ultrasonic for 15min, and finally blow dry with Ar gas, in 6M HNO 3 Soak in aqueous solution at 50°C for 3 hours, wash with deionized water, dry with Ar gas, and measure the static water contact angle as 100 degrees;

[0048] 2. Porous metal electrode pretreatment: at room temperature, porous Cu sheets with a length and width of 4 cm and 5 cm, a thickness of 0.1 mm, a purity of 99.5%, an average pore diameter of 0.5 mm, and a porosity of 1% were placed in acetone and 0.5MH 2 SO 4 Ultrasonic soaking in medium for 20 minutes, degreasing and deoxidizing film treatment, then cleaning with absolute ethanol, ultrasonic soaking for 15 minutes, and finally drying with Ar gas;

[0049] 3. Cut two pieces of po...

Embodiment 2

[0055] 1. Gas diffusion substrate degreasing pretreatment: At room temperature, carbon cloth with a length and width of 4cm and 5cm, a thickness of 2.0mm, and a porosity of 80% is ultrasonically soaked in acetone for 30 minutes, and then cleaned with absolute ethanol , Ultrasonic soaking for 15min, and finally drying with Ar gas; in 6M HNO 3 Soak in aqueous solution at 50°C for 1 hour, wash with deionized water, dry with Ar gas, and measure the static water contact angle to be 130 degrees;

[0056] 2. Porous metal electrode pretreatment: at room temperature, porous Ag foil with a length and width of 4 cm and 5 cm, a thickness of 50 μm, a purity of 99.0%, an average pore diameter of 50 μm, and a porosity of 0.5% was prepared in acetone and 0.5MH 2 SO 4 Ultrasonic immersion in medium for 30 minutes, surface degreasing and oxide film removal, then cleaning with absolute ethanol, ultrasonic immersion for 15 minutes, and finally drying with Ar gas;

[0057] 3. Cut two pieces of p...

Embodiment 3

[0063] 1. Gas diffusion substrate degreasing pretreatment: At room temperature, soak a circular carbon felt with a diameter of 2.0 cm, a thickness of 3.0 mm, and a porosity of 95% in acetone for 30 minutes, then clean it with absolute ethanol, and ultrasonically Soak for 15 minutes, and finally dry it with Ar gas, and measure the static water contact angle as 130 degrees;

[0064] 2. Porous metal electrode pretreatment: at room temperature, a circular porous Pd sheet with a diameter of 2.0cm, a thickness of 0.2mm, a purity of 99.5%, an average pore diameter of 1.0mm, and a porosity of 0.1% was ultrasonically soaked in acetone for 30min , carry out surface degreasing treatment, then clean with absolute ethanol, soak in ultrasonic for 15min, and finally blow dry with Ar gas;

[0065] 3. Cut two pieces of polyimide coated with acrylate pressure-sensitive adhesive on one side into a circular frame, the outer diameter of the frame is 3.0cm, and the diameter of the hollow part (refe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com