Functional chinlon FDY fiber and preparation method of finishing agent

A functional and finishing agent technology, applied in the field of spinning materials, can solve the problems of not being able to meet the various needs of daily wear and single function, and achieve the effects of long-lasting anti-ultraviolet effect, improved comfort and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

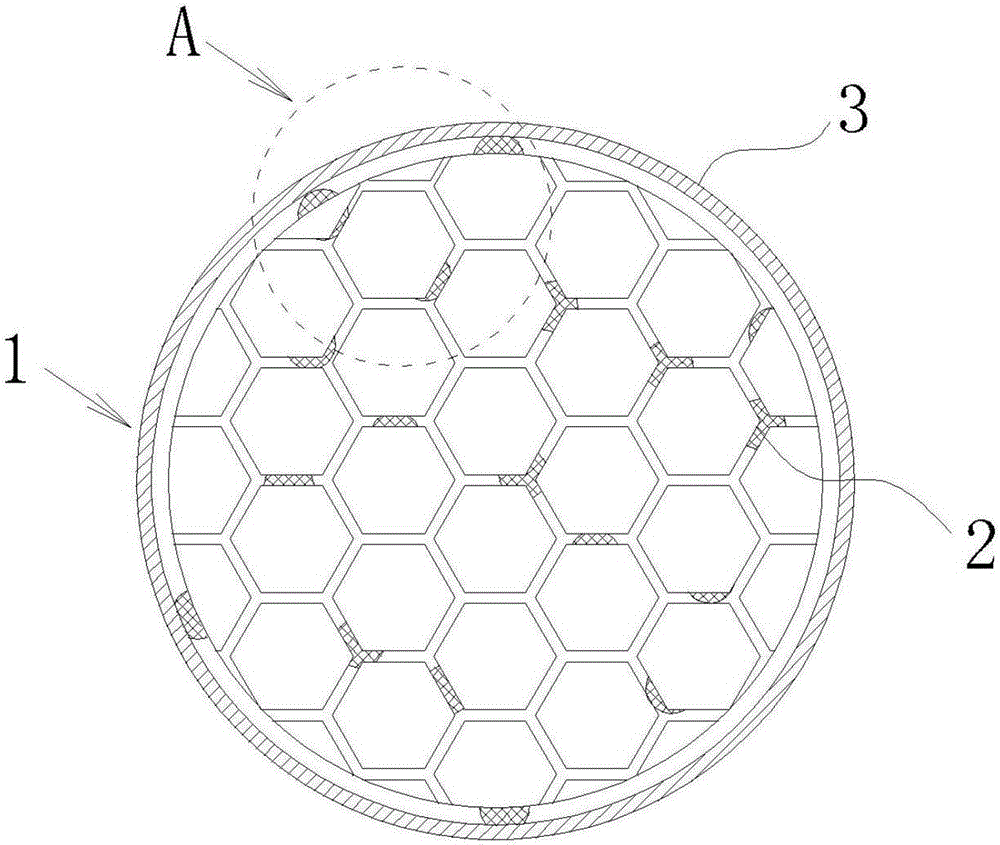

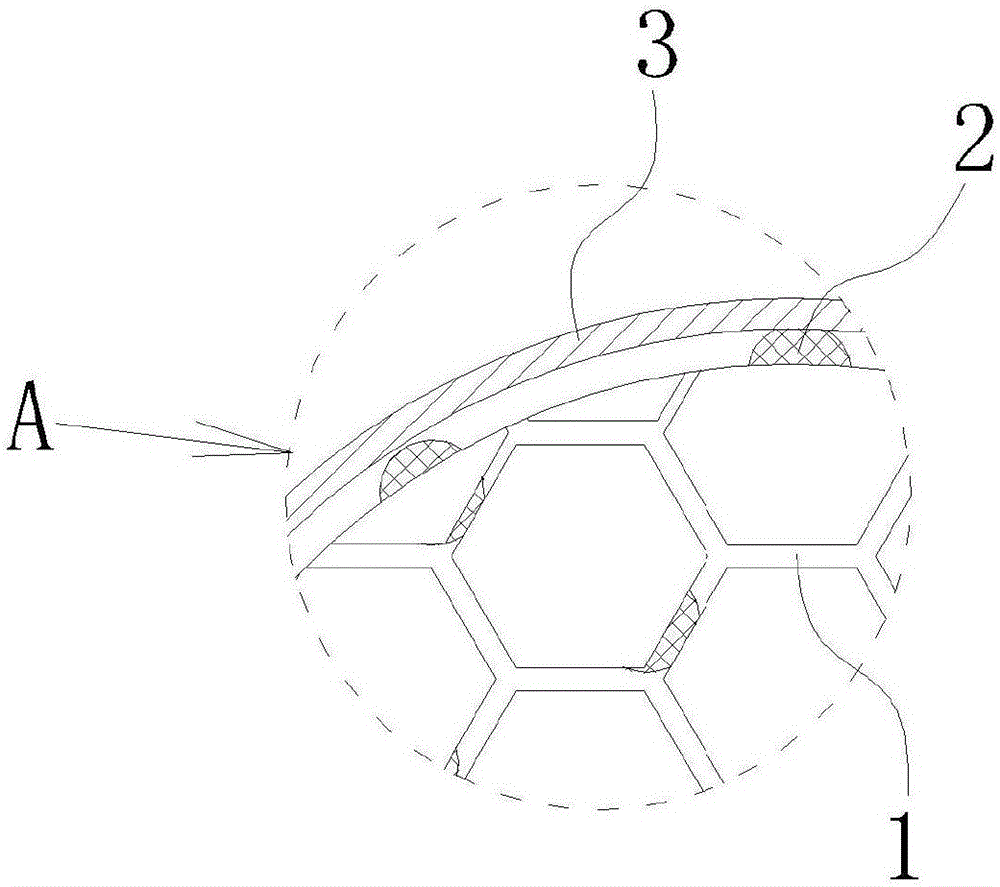

[0039] Such as figure 1 and figure 2 As shown, a functional nylon FDY fiber disclosed in the first embodiment of the present invention includes a fiber body 1 . As an inventive point of the present invention, the fiber body 1 is a hollow fiber, and the cross section of the hollow fiber body 1 is honeycomb-shaped, thereby improving the air permeability of the fiber body 1 and increasing the elasticity. As a preference, the fiber body 1 of a functional nylon FDY fiber disclosed in this embodiment of the present invention is also provided with a heat-retaining fiber 2. As a further preference, in this embodiment of the present invention, the heat-retention fiber 2 is a short filament, Such as figure 1 and figure 2 As shown, the thermal fiber 2 is embedded in the fiber body 1 and integrated with the fiber body 1 . The heat-retaining fiber 2 has many options, such as cotton fiber, or soybean protein fiber, or cotton fiber and soybean protein fiber, and in this embodiment of t...

Embodiment 2

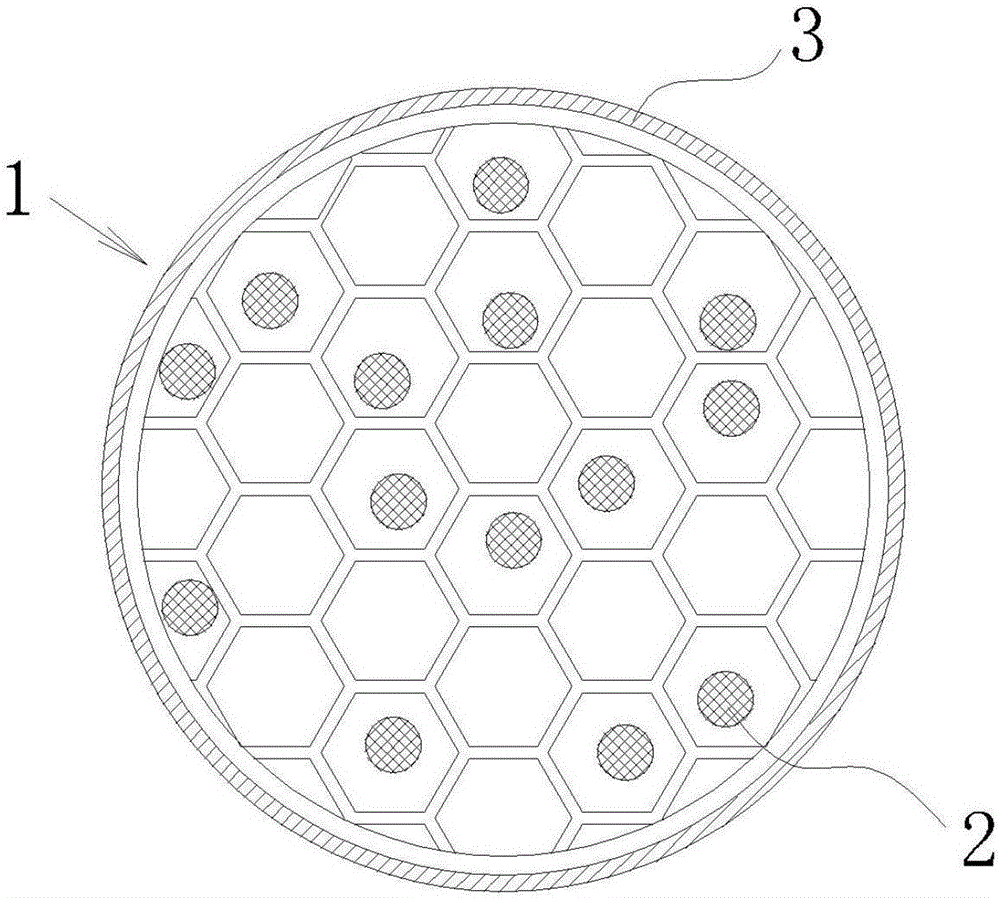

[0042] Such as image 3 As shown, a functional nylon FDY fiber disclosed in the second embodiment of the present invention has basically the same structure as in Example 1, except that the thermal fiber 2 is a filament, such as image 3 As shown, the heat-retaining fiber 2 is threaded in the honeycomb cavity of the fiber body 1, and the heat-retaining fiber 2 can be distributed evenly or regularly, and there is no limitation here.

[0043] A functional nylon FDY fiber disclosed in the above two embodiments improves the thermal performance and air permeability of the fiber, thus improving the wearing comfort.

[0044]The present invention also discloses a production process of a functional nylon FDY fiber provided in the above-mentioned embodiment 1 and embodiment 2, which specifically includes the following steps:

Embodiment 3

[0046] The production process of a kind of functional nylon FDY fiber that above-mentioned embodiment 1 provides specifically comprises the following steps:

[0047] A) preparing materials, storing the raw materials in the silo in advance, preferably, the silo is filled with nitrogen protection gas, and the residence time of the raw materials in the silo is less than 24h;

[0048] B) Melting, introducing raw materials and thermal insulation fibers into a screw extruder with heating function to melt at the same time to obtain a raw material melt, during which the raw materials and thermal insulation fibers are mixed;

[0049] Preferably, the heating temperature of the screw extrusion is between 250°C and 260°C. Specifically, the screw extruder is equipped with six heating zones, the temperature of the first heating zone is 250°C, the temperature of the second heating zone is 254°C, the temperature of the third heating zone is 256°C, and the temperature of the fourth heating zon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com