Pretreatment technology for detecting polybrominated diphenyl ethers residue in vegetables

A polybrominated diphenyl ether and vegetable technology, which is applied in the field of analytical chemistry, can solve the problems of large consumption of organic solvents, complicated purification process and high detection cost, and achieves the effects of less organic solvent consumption, high extraction efficiency and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

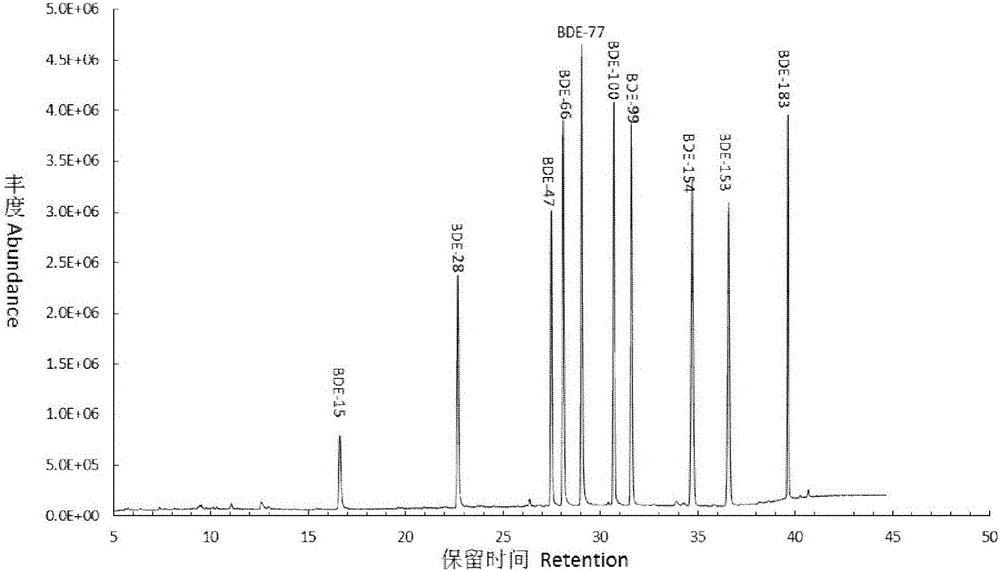

[0038] This embodiment focuses on the GC-ECD analysis of polybrominated diphenyl ethers (PBDEs) in the standard solution to ensure the qualitative and quantitative accuracy of PBDEs.

[0039] Step 1: Take 500 μL of the above 10 kinds of PBDEs mixed standard stock solution in a 2 mL injection bottle, add 500 μL of n-hexane to dilute to 500 μg L -1 , and then serially diluted to 250 μg L in new vials -1 , 100μg L -1 , 50μgL -1 , 25 μg L -1 , 10 μg L -1 , 5 μg L -1 , detected using GC-ECD.

[0040] Step 2: Set the chromatographic condition parameters: the chromatographic column is a DB-5 column (30m×0.32mm×0.25μm), the temperature of the injection port is 265°C, the carrier gas is nitrogen, the flow rate is 2mL / min, and the detector temperature is 298 ℃, the injection volume was 1 μL, splitless injection.

[0041] Step 3: Set the heating program: the initial temperature is 140°C, keep for 2min, rise to 180°C at 5°C / min, keep for 5 minutes; rise to 265°C at 5°C / min, keep fo...

Embodiment 2

[0048] This example focuses on the accelerated solvent extraction (ASE) of 10 kinds of PBDEs in vegetables, and optimizes the extraction conditions of ASE.

[0049] Step 1. Wash the surface of the vegetable sample with deionized water, dry the surface moisture under natural conditions, cut into pieces of about 0.5cm with scissors, accurately weigh the sample in a mortar, add 50μL 100μg L -1 The mixed standard solution of 10 kinds of PBDEs was added with 1g of quartz sand and 2g of diatomaceous earth, fully ground and transferred to the ASE stainless steel extraction pool, and extracted by ASE 200 accelerated solvent extraction (DIONEX, USA). Using n-hexane: acetone (4:1, v / v) for extraction, the furnace temperature of the extraction pool is 100°C, and the pressure is 1500Psi. Extraction process: heating for 5 minutes, static extraction for 5 minutes to flush 60% of the volume, nitrogen purging for 60 seconds, and cycle 2 times.

[0050] Step 2. Use n-hexane: dichloromethane ...

Embodiment 3

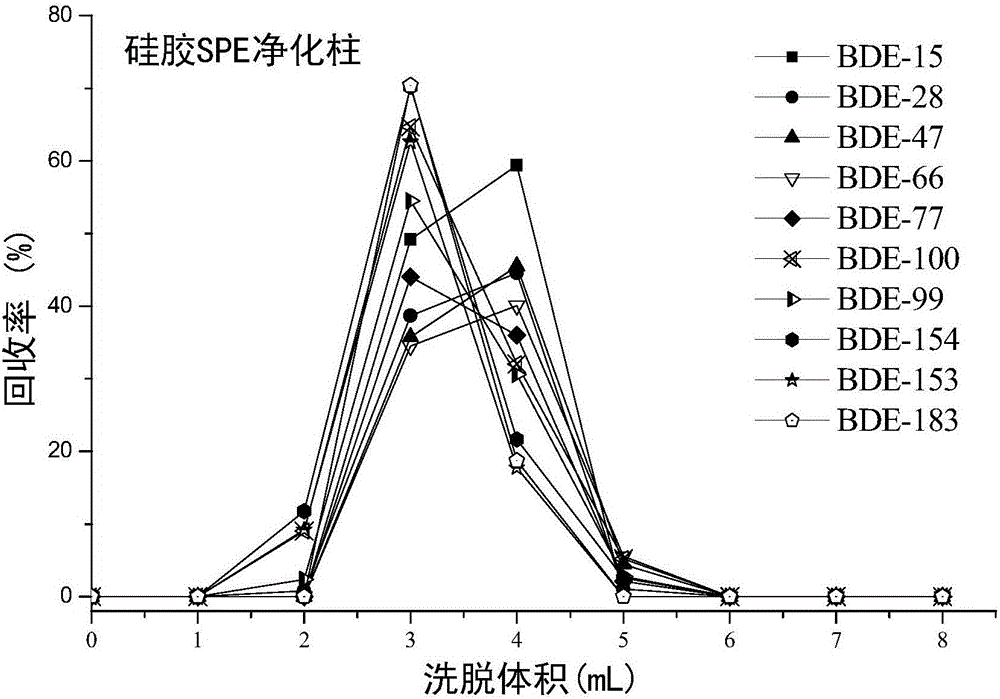

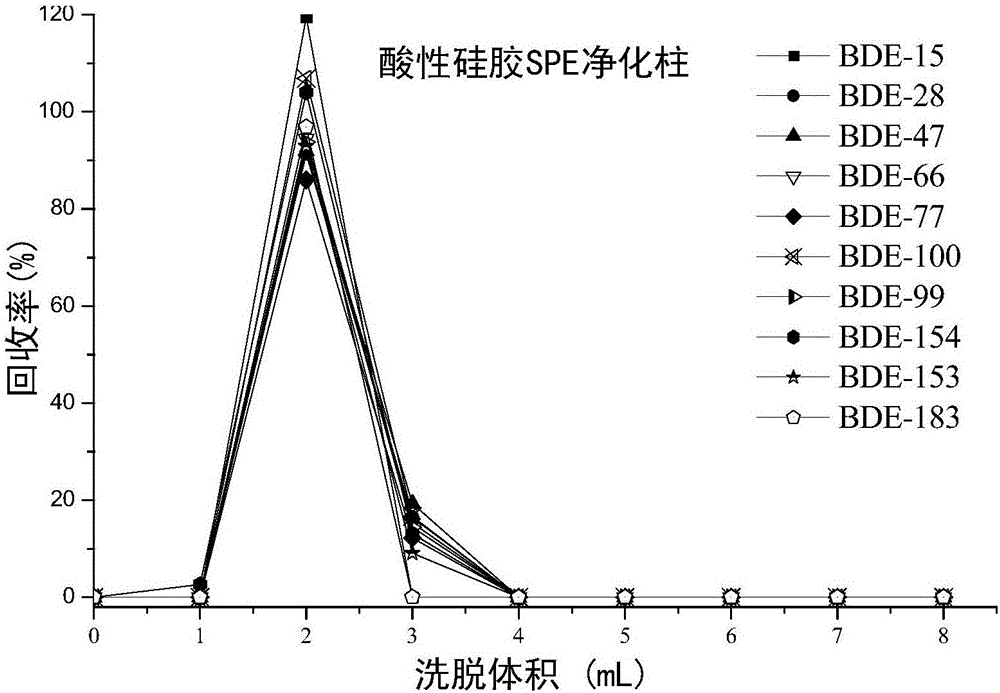

[0059] This example focuses on the preparation process of the self-prepared SPE purification column and its elution behavior of PBDEs.

[0060] Step 1. Select two kinds of fillers commonly used in the laboratory, silica gel and florisil. The treatment steps of the two fillers are as follows: (1) Deactivation: the filler is placed in an evaporating dish, and baked in an oven at 200 ° C for 12 hours , transferred to a desiccator, cooled to room temperature, and set aside; (2) Activation: The filler needs to be activated before use: take an appropriate amount of filler, add 5% (mass ratio) deionized water, mix well, and place on a shaker to vibrate and mix. Mix well until there are no lumps in the filling, and equilibrate overnight. Acidic silica gel was prepared by modification with concentrated sulfuric acid. The specific steps are as follows: Weigh the filler and place it in a flask, add concentrated sulfuric acid drop by drop according to filler: concentrated sulfuric acid 5:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com