High-tenacity and low-temperature-resistance resin matrix and preparation method thereof

A technology of resin matrix and low temperature resistance. It is applied in the field of carbon fiber resin matrix composite materials. It can solve the problems of insufficient low temperature resistance and unsuitable process characteristics, and achieve the effects of improved low temperature resistance, long service life and improved mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

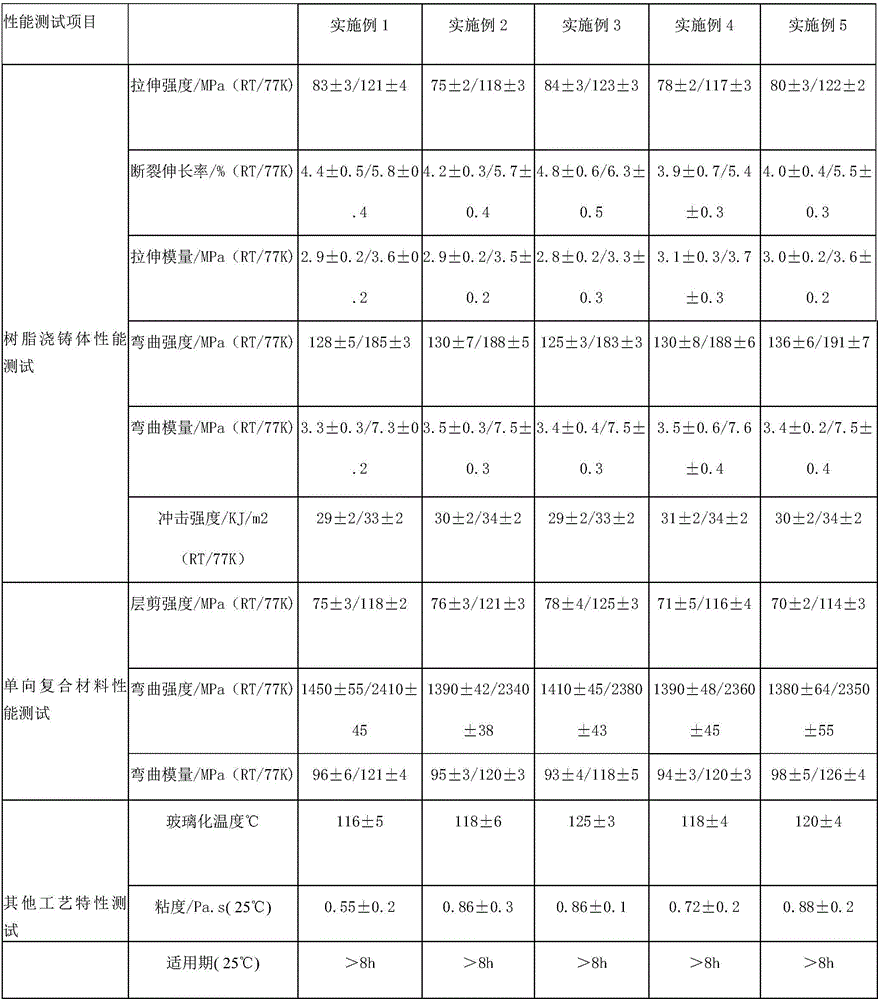

Examples

Embodiment 1

[0026] The main epoxy resin is cycloaliphatic bis(7-oxabicyclo[4.1.0]3-heptylmethyl adipate) (UVR6128), the toughening component is polyurethane-epoxy resin, and the nanoparticles are carboxyl functional 1,6-hexanediol diglycidyl ether X-652 is used as diluent, and alicyclic amine 3,3′-dimethyl 4,4′-diaminodicyclohexyl is used as curing agent Methane (DMDC), the accelerator uses 2-ethyl-4-methylimidazole, and the carbon fiber uses T700 from Toray Corporation of Japan. The mass ratio of the main epoxy resin, the toughening component, the nanoparticles, the diluent, the curing agent and the accelerator is 100:150:0.5:230:110:0.8. The preparation process is as follows: dehydrate and dry the polyol at 120°C for 3 hours, then cool to 50°C and add isocyanate at a rate of 3mL / min. Mix evenly under the condition of 10 minutes, then react in nitrogen atmosphere under the conditions of oil bath temperature 70°C, stirring speed 800 rpm, time 120 minutes, the reaction is terminated when ...

Embodiment 2

[0029] The main epoxy resin is 1,3-diglycidyl-5,5-dimethylhydantoin epoxy resin (DMH-EP), the toughening component is polyurethane-epoxy resin, and the nanoparticles are functionalized with carboxyl groups The multi-walled carbon nanotubes and diluent adopt glycidyl ether type epoxy resin 662, and the curing agent adopts alicyclic amine 3,3'-dimethyl 4,4'-diaminodicyclohexylmethane (DMDC) and polyether The compound of amine D-230, the accelerator uses 2-ethyl-4-methylimidazole, and the carbon fiber uses T700 from Toray Corporation of Japan. The mass ratio of the main epoxy resin, the toughening component, the nanoparticles, the diluent, the curing agent and the accelerator is 100:120:0.5:150:170:1. The preparation process is as follows: dehydrate and dry the polyol at 120°C for 3 hours, then cool to 50°C and add isocyanate at a rate of 3mL / min. Mix evenly under the condition of 10 minutes, then react in nitrogen atmosphere under the conditions of oil bath temperature 70°C, st...

Embodiment 3

[0032] The main epoxy resin is hydantoin-bisphenol A epoxy resin (DMH-BPA-EP), the toughening component is polyurethane-epoxy resin, the nanoparticles are carboxyl-functionalized graphene oxide, and the diluent is glycidyl ether. Type epoxy resin 662, polyetheramine D-230 is used as curing agent, 2,4,6-tris(dimethylaminomethyl)phenol is used as accelerator, and T700 is used as carbon fiber from Japan Toray Company. The mass ratio of the main epoxy resin, the toughening component, the diluent, the curing agent and the accelerator is 100:130:0.5:120:120:4. The preparation process is as follows: dehydrate and dry the polyol at 120°C for 3 hours, then cool to 50°C and add isocyanate at a rate of 3mL / min. Mix evenly under the condition of 10 minutes, then react in nitrogen atmosphere under the conditions of oil bath temperature 70°C, stirring speed 800 rpm, time 120 minutes, the reaction is terminated when the content of isocyanate is controlled at 1%-2%, and the polyurethane prepo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com