Composite shape-stabilized phase change material and preparation method thereof

A shape-setting phase-change material and a technology for phase-change materials, which are applied in the field of composite shape-setting phase-change materials and their preparation, can solve problems such as poor thermal stability, and achieve the effects of reduced phase separation, low price, and simple and convenient preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

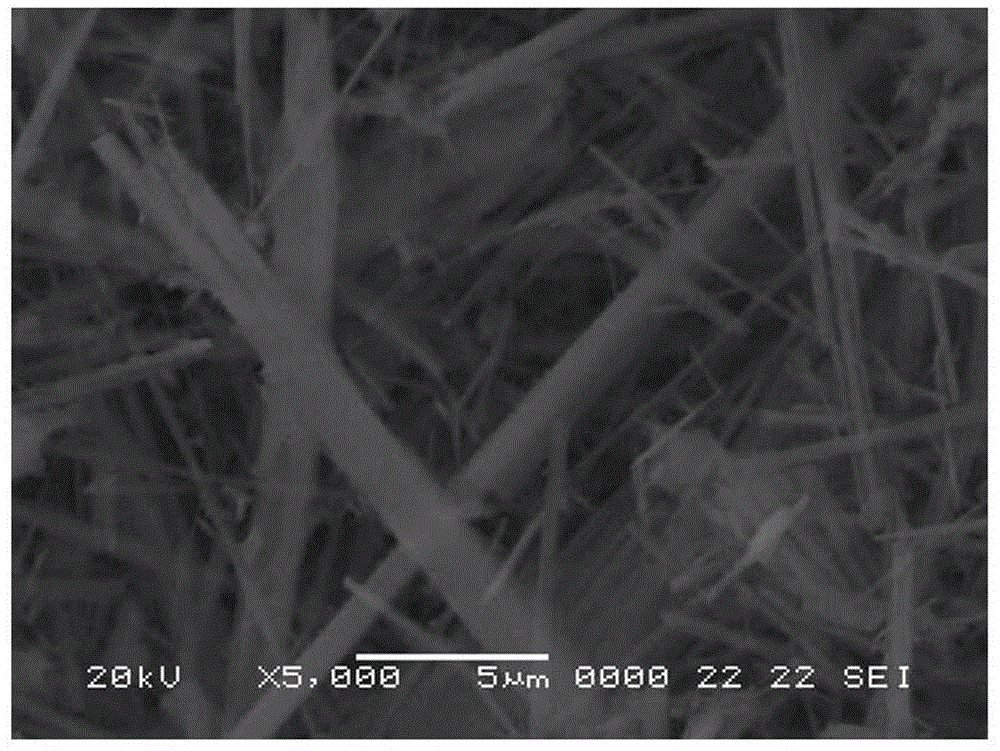

[0032] Step 1: Acid treatment of sepiolite

[0033] Sepiolite and hydrochloric acid (0.1 mol / L) were mixed with a solid-to-liquid ratio of 1:20, ultrasonicated and stirred for 1 hour, then left to stand for 12 hours to remove the quartz impurities at the bottom, washed repeatedly until neutral, suction filtered, dried, grind.

[0034] Step 2: High temperature treatment of sepiolite

[0035] Put the sepiolite obtained in step 1 into the muffle furnace, 420 o C activated for 2 h.

[0036] Step 3: Organic treatment of sepiolite

[0037] The 5g sepiolite that step 2 obtains is configured into the suspension of 20 g / L, pours in the three-necked flask, 50 o C Preheat for 15min. The silane coupling agent hydrolyzate obtained by mixing and shaking 2 ml KH570 (1% mass fraction) and 100 ml ethanol solution (95% mass fraction) for 30 min was added to a three-necked flask, and then sodium hexametaphosphate (mass fraction was 7%) as a dispersant, 95 o C was refluxed and condensed fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com