A method for reducing the inhibition effect of by-products in lignocellulose alkaline pretreatment liquid and preparation of cellulosic ethanol based on this method

A technology of lignocellulose and pretreatment liquid, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of increasing process complexity, time-consuming, additional consumption of reagents and energy, and achieve the goal of promoting Industrial application, simple equipment requirements, and the effect of eliminating inhibition effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

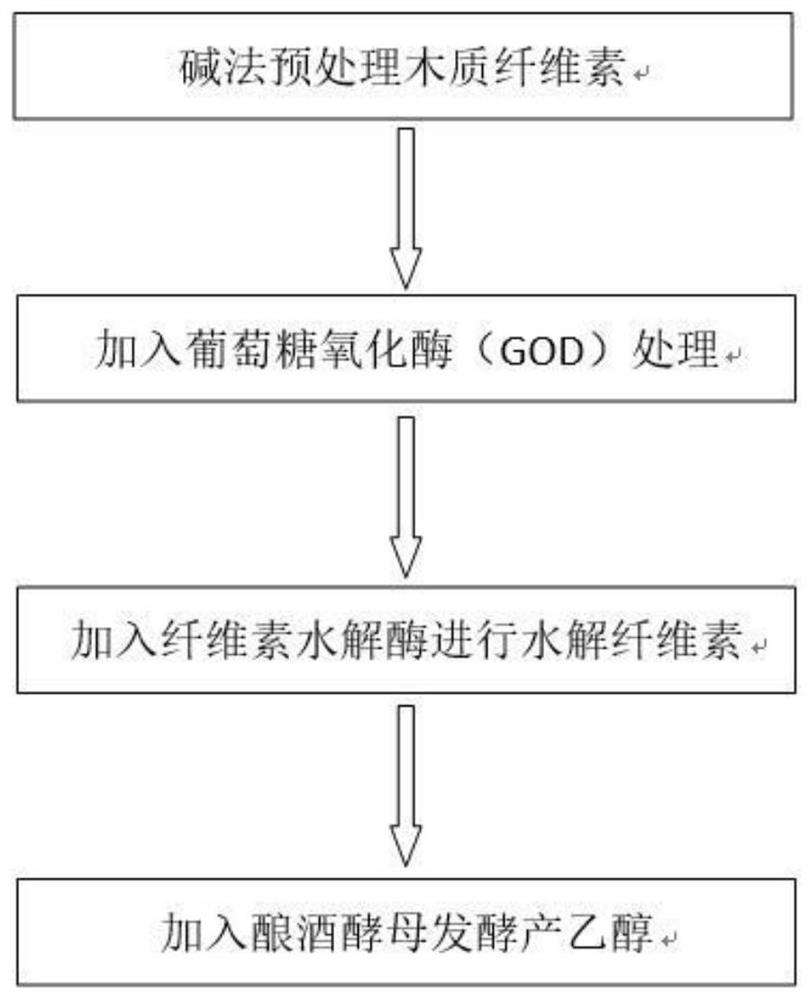

Method used

Image

Examples

Embodiment 1

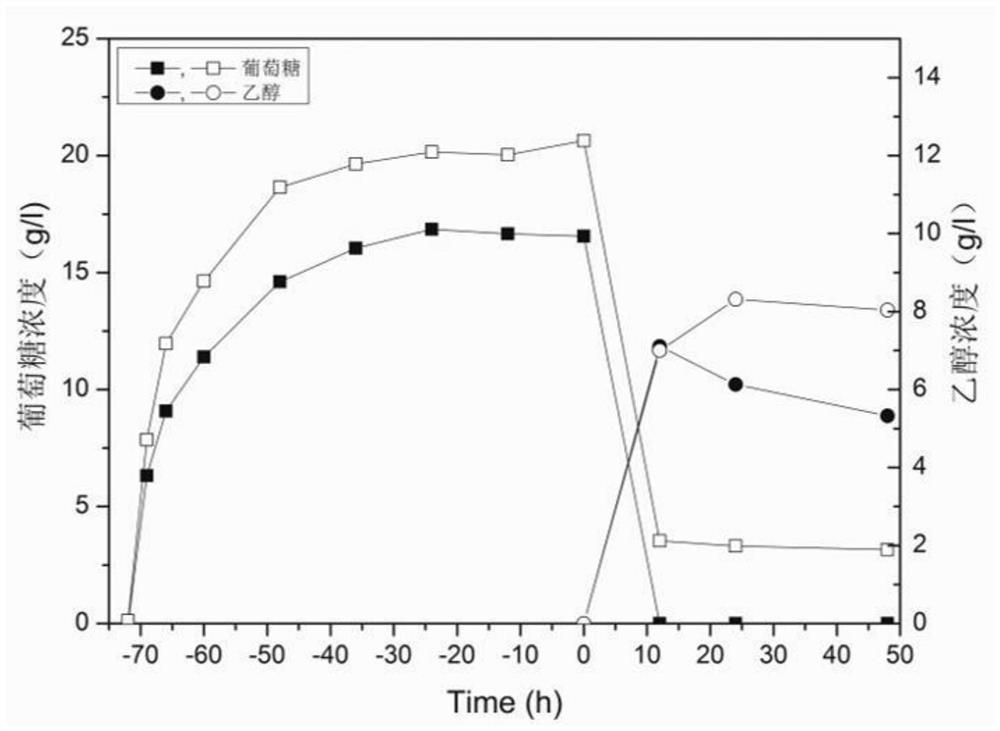

[0033] GOD treatment of bagasse pretreated with 1% NaOH and fermentation to produce ethanol

[0034] S1: Accurately weigh 2.5 g of bagasse, add 1% NaOH solution at a liquid-solid ratio of 10:1 (substrate concentration 10% (w / v)), treat bagasse at 121°C for 1 hour, and cool at room temperature to obtain a pre- treatment fluid;

[0035] S2: Under sterile conditions, add commercially available concentrated phosphoric acid to the pretreatment solution, adjust the pH to about 5, then add 10U GOD, detoxify at 30°C, 200rpm for 24h;

[0036] S3: Under sterile conditions, add cellulase to the above pretreatment solution, and fix the ratio of enzyme addition to substrate at 6 mg enzyme / g substrate, then place it in a constant temperature shaker, hydrolyze at 45 °C, 160 rpm for 72 hours; During the hydrolysis process, samples were taken to measure the enzymatic hydrolysis of bagasse;

[0037] S4: Then add peptone to a final concentration of 20g / L, and insert the pre-activated Saccharom...

Embodiment 2

[0040] GOD treatment of 2% NaOH pretreated bagasse and fermentation to produce ethanol

[0041] S1: Accurately weigh 2.5 g of bagasse, add 2% NaOH solution at a liquid-solid ratio of 10:1 (substrate concentration 10% (w / v)), treat bagasse at 121°C for 1 hour, and cool at room temperature to obtain a pre- treatment fluid;

[0042] S2: Under sterile conditions, add commercially available concentrated phosphoric acid to the pretreatment solution, adjust the pH to about 5, then add 15U GOD, detoxify at 30°C, 200rpm for 24h;

[0043] S3: Under sterile conditions, add cellulase to the above pretreatment solution, and fix the ratio of enzyme addition to substrate at 6 mg enzyme / g substrate, then place it in a constant temperature shaker, hydrolyze at 45 °C, 160 rpm for 72 hours; During the hydrolysis process, samples were taken to measure the enzymatic hydrolysis of bagasse;

[0044] S4: Then add peptone to a final concentration of 20g / L, and insert the pre-activated Saccharomyces ...

Embodiment 3

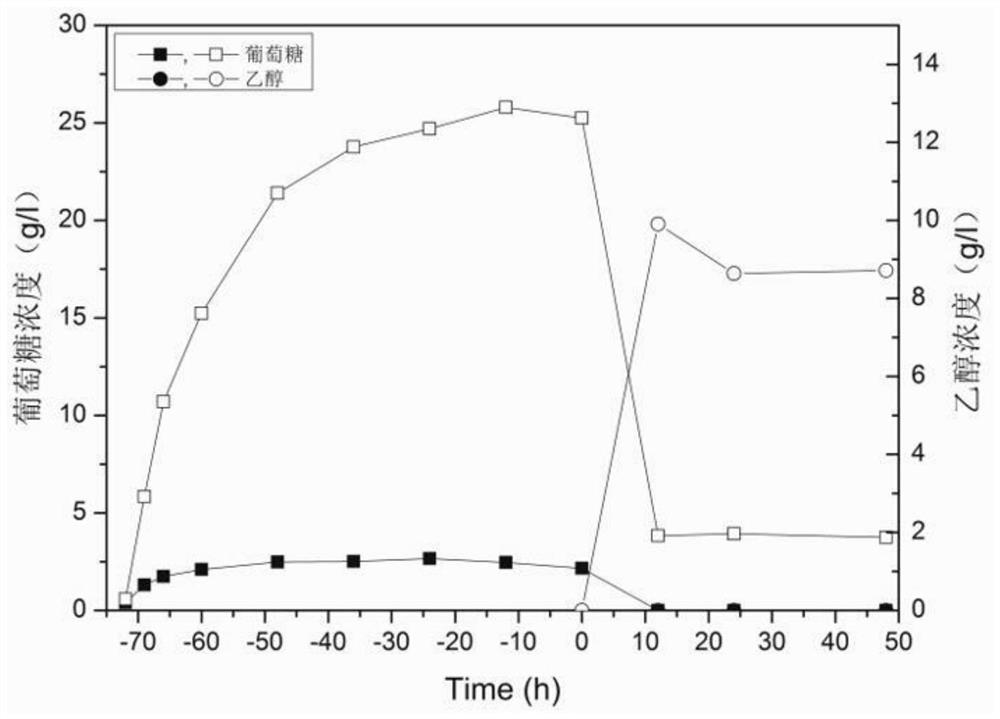

[0047] GOD treatment of 3% NaOH pretreated bagasse and fermentation to produce ethanol

[0048] S1: Accurately weigh 2.5 g of bagasse, add 3% NaOH solution at a liquid-solid ratio of 10:1 (substrate concentration 10% (w / v)), treat bagasse at 121°C for 1 hour, and cool at room temperature to obtain a pre- treatment fluid;

[0049] S2: Under sterile conditions, add commercially available concentrated phosphoric acid to the pretreatment solution to adjust the pH to about 5, then add 25U GOD, detoxify at 30°C, 200rpm for 24h;

[0050] S3: Under sterile conditions, add cellulase to the above pretreatment solution, and fix the ratio of enzyme addition to substrate at 6 mg enzyme / g substrate, then place it in a constant temperature shaker, hydrolyze at 45 °C, 160 rpm for 72 hours; During the hydrolysis process, samples were taken to measure the enzymatic hydrolysis of bagasse;

[0051] S4: Then add peptone to a final concentration of 20g / L, and insert the pre-activated Saccharomyce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com