Production method of microbial flora for processing ammonia containing wastewater

A microbial flora and production method technology, applied in the field of environmental microorganisms, can solve the problems of bacterial flora cultivation levels and long cultivation time, high product prices, and low scale production efficiency, so as to improve sedimentation and stability, and realize The effect of rapid value-added and large production volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

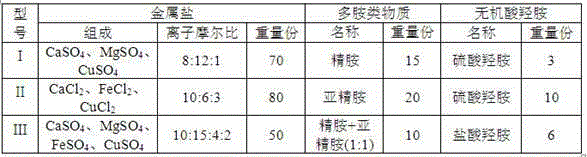

Embodiment 1

[0029] The microbial flora enriched and domesticated in this laboratory was used as the inoculum for mass production. Firstly, the inoculum was inoculated into a 10L reactor for primary scale-up cultivation of the bacteria. The initial biomass was 2g, and the volume of the initial culture solution was 5L. The ammonia nitrogen concentration in the initial culture solution was 800mg / L, and the COD was 46mg / L. When the ammonia nitrogen removal rate reaches 80%, add ammonium chloride solution with an ammonia nitrogen concentration of 15g / L to make the ammonia nitrogen concentration in the culture medium 800-1000mg / L, and add microbial growth promoter I at the same time to make the culture medium The accelerator concentration is 15mg / L. Cultivate until the material in the reactor reaches 9L, at this point the reaction is terminated, the supernatant is discharged after natural settlement, and the bacteria are transferred to a 60L reactor for second-stage cultivation.

[0030] The ...

Embodiment 2

[0032] The microbial flora enriched and domesticated in this laboratory was used as the inoculum for mass production. Firstly, the inoculum was inoculated into a 20L reactor for primary scale-up cultivation of the bacteria. The initial culture medium volume was 10L, and the MLSS after inoculation was 0.9g / L. The ammonia nitrogen concentration in the initial culture solution was 1000mg / L, and the COD was 80mg / L. When the ammonia nitrogen removal rate reaches 80%, add ammonium sulfate solution with an ammonia nitrogen concentration of 25g / L to make the ammonia nitrogen concentration in the culture medium 900-1000mg / L, and add microbial growth promoter II at the same time to make the culture medium promote The dosage concentration is 25mg / L. Cultivate until the material in the reactor reaches 18L, at this point the reaction is terminated, the supernatant is discharged after natural settlement, and the bacteria are transferred to a 100L reactor for second-stage cultivation.

[0...

Embodiment 3

[0035] The microbial flora enriched and domesticated in this laboratory was used as the inoculum for mass production. Firstly, the inoculum was inoculated into a 10L reactor for primary scale-up cultivation of the bacteria. The initial culture medium volume was 5L, and the MLSS after inoculation was 0.9g / L. The ammonia nitrogen concentration in the initial culture solution was 1000mg / L, and the COD was 80mg / L. When the ammonia nitrogen removal rate reaches 80%, add ammonium sulfate solution with an ammonia nitrogen concentration of 25g / L to make the ammonia nitrogen concentration in the culture medium 1000-1200mg / L, and add microbial growth promoter III at the same time to make the culture medium promote The dosage concentration is 30mg / L. Cultivate until the material in the reactor reaches 9L, at this point the reaction is terminated, the supernatant is discharged after natural settlement, and the bacteria are transferred to a 100L reactor for second-stage cultivation.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com