Electrostatic layer-by-layer self assembling technology modified bioengineering porcine cornea and production method thereof

A layer-by-layer self-assembly and bioengineering technology, applied in the medical field, can solve the problems of limiting the application of corneal transplantation, large variability of vision restoration, and large destructiveness of corneal tissue, so as to enhance the ability to resist pathological environments and promote visual function. Restoration, light transmittance ideal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

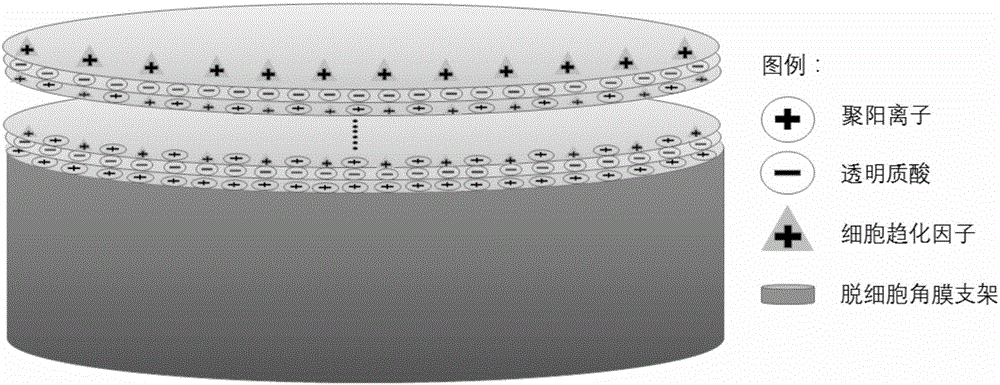

[0032] The bioengineered porcine cornea modified by electrostatic layer-by-layer self-assembly technology, the specific preparation process is as follows:

[0033] 1) Clean the bioengineered porcine cornea with a bicarbonate mixed solution, and then dry it for 8 minutes at a temperature of 30 degrees Celsius in an ultra-clean bench;

[0034]2) Immerse the dried bioengineered porcine cornea in a positively charged chitosan aqueous solution with a concentration of 1 mg / ml and pH 3.0, absorb for 5 minutes, and rinse with deionized water; then immerse the bioengineered porcine cornea in a negatively charged concentration of 10mg / ml, pH6.0 sodium hyaluronate solution, adsorption for 30 minutes, rinsed with deionized water; In the chemical factor solution, absorb for 30 minutes, and then rinse with deionized water;

[0035] 3) Repeat step 2) 20 times, so that the polycation, hyaluronic acid layer and cell chemokine layer are alternately adsorbed on the surface of the bioengineered ...

Embodiment 2

[0038] The bioengineered porcine cornea modified by electrostatic layer-by-layer self-assembly technology, the specific preparation process is as follows:

[0039] 1) Clean the bioengineered porcine cornea with a bicarbonate mixed solution, and then dry it for 10 minutes at a temperature of 20 degrees Celsius in an ultra-clean bench;

[0040] 2) Immerse the dried bioengineered porcine cornea into a positively charged polylysine aqueous solution with a concentration of 10 mg / ml and pH6.0, absorb for 30 minutes, and rinse with deionized water; In the sodium hyaluronate solution with a charge concentration of 1 mg / ml and a pH of 3.0, absorb for 5 minutes and rinse with deionized water; In the chemokine solution, adsorb for 5 minutes, and then rinse with deionized water;

[0041] 3) Repeat step 2) 10 times, so that the polycation, hyaluronic acid layer and cell chemokine layer are alternately adsorbed on the surface of the bioengineered pig cornea, and ensure that the outermost l...

Embodiment 3

[0044] The bioengineered porcine cornea modified by electrostatic layer-by-layer self-assembly technology, the specific preparation process is as follows:

[0045] 1) Clean the bioengineered porcine cornea with a bicarbonate mixed solution, and then dry it for 12 minutes at a temperature of 10 degrees Celsius in an ultra-clean bench;

[0046] 2) Immerse the dried bioengineered porcine cornea in a positively charged chitosan aqueous solution with a concentration of 6 mg / ml and pH 4.5, absorb for 18 minutes, and rinse with deionized water; then immerse the bioengineered porcine cornea in a negatively charged solution. The concentration of 6mg / ml, pH4.5 sodium hyaluronate solution, adsorption for 18 minutes, rinsed with deionized water; In the chemical factor solution, absorb for 20 minutes, and then rinse with deionized water;

[0047] 3) Repeat step 2) 15 times, so that the polycation, hyaluronic acid layer and cell chemokine layer are alternately adsorbed on the surface of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com