Ag-CoSe2 nanoribbon and preparation method and purpose thereof

A technology of nanobelt and deionized water, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of unfavorable catalyst structure, unfavorable large-scale preparation, increase time cost, etc., to achieve Excellent catalytic activity, uniform size, and reduced synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Ag-CoSe 2 The preparation method of nanobelt, comprises the following steps:

[0034] (1) Two-dimensional CoSe 2 - Preparation of DETA nanobelts

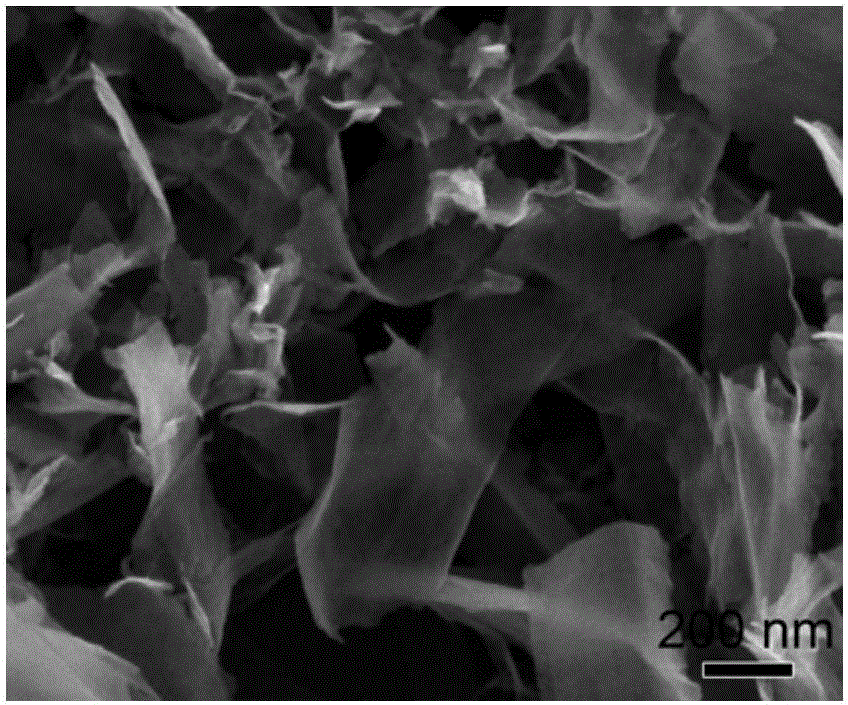

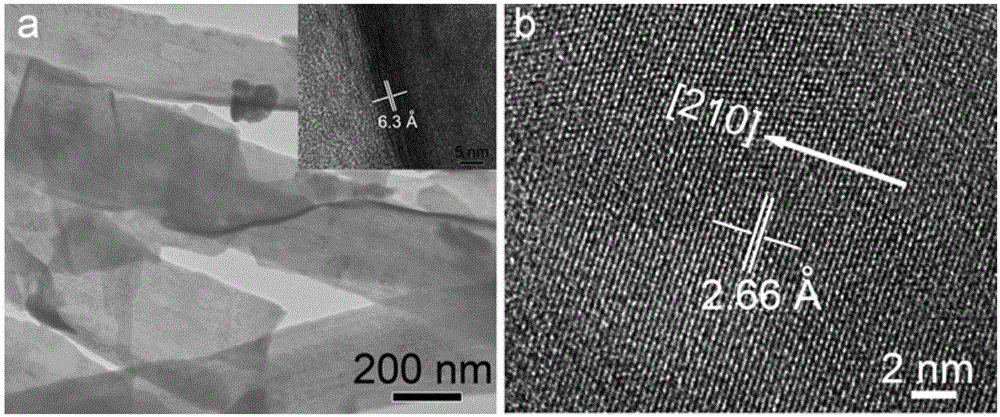

[0035]At room temperature, add 249 mg cobalt acetate and 173 mg sodium selenite to a 50 mL glass beaker containing a mixed solution of 13.333 mL deionized water and 26.666 mL diethylenetriamine successively, and magnetically stir the mixed solution at room temperature for 30 Minutes, then transferred to a hydrothermal kettle with a volume of 50mL, and continued to heat at 180°C for 16 hours to obtain the following figure 1 As shown, 2D CoSe with an average width of 300–500 nm 2 -DETA nanobelt solution, and finally the two-dimensional CoSe 2 -The solution of DETA nanobelts was centrifuged, washed with a mixture of deionized water and ethanol, and dried to obtain two-dimensional CoSe 2 - DETA nanoribbons;

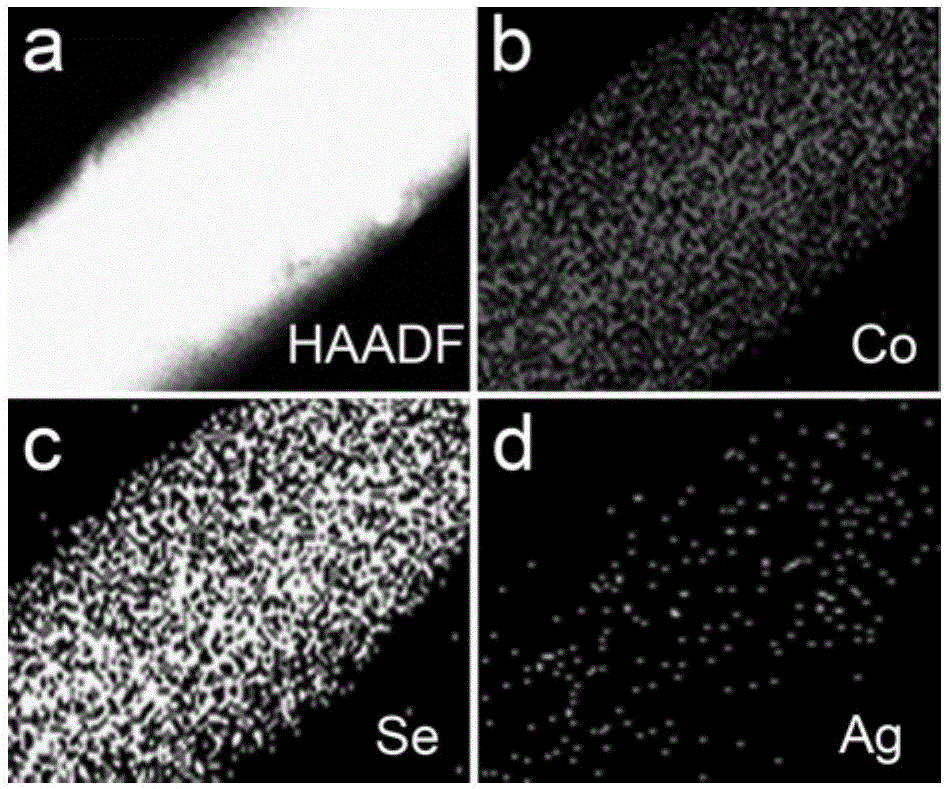

[0036] (2)Ag-CoSe 2 Preparation of nanoribbons

[0037] At room temperature, add 21mg of two-dimensional CoSe to a...

Embodiment 2

[0039] Ag-CoSe 2 The preparation method of nanobelt, comprises the following steps:

[0040] (1) Two-dimensional CoSe 2 - Preparation of DETA nanobelts

[0041] At room temperature, add 249 mg cobalt acetate and 173 mg sodium selenite to a 50 mL glass beaker containing a mixed solution of 13.333 mL deionized water and 26.666 mL diethylenetriamine successively, and magnetically stir the mixed solution at room temperature for 30 Minutes, then transferred to a hydrothermal kettle with a volume of 50mL, and continued to heat at 175°C for 16 hours to obtain a two-dimensional CoSe with an average width of 300-500nm 2 -DETA nanobelt solution, and finally the two-dimensional CoSe 2 -The solution of DETA nanobelts was centrifuged, washed with a mixture of deionized water and ethanol, and dried to obtain two-dimensional CoSe 2 - DETA nanoribbons;

[0042] (2)Ag-CoSe 2 Preparation of nanoribbons

[0043] At room temperature, add 21mg of two-dimensional CoSe to a 20mL glass reactio...

Embodiment 3

[0045] Ag-CoSe 2 The preparation method of nanobelt, comprises the following steps:

[0046] (1) Two-dimensional CoSe 2 - Preparation of DETA nanobelts

[0047] At room temperature, add 249 mg cobalt acetate and 173 mg sodium selenite to a 50 mL glass beaker containing a mixed solution of 13.333 mL deionized water and 26.666 mL diethylenetriamine successively, and magnetically stir the mixed solution at room temperature for 30 Minutes, then transferred to a hydrothermal kettle with a volume of 50mL, and continued to heat at 185°C for 16 hours to obtain a two-dimensional CoSe with an average width of 300-500nm 2 -DETA nanobelt solution, and finally the two-dimensional CoSe 2 -The solution of DETA nanobelts was centrifuged, washed with a mixture of deionized water and ethanol, and dried to obtain two-dimensional CoSe 2 - DETA nanoribbons;

[0048] (2)Ag-CoSe 2 Preparation of nanoribbons

[0049] At room temperature, add 21mg of two-dimensional CoSe to a 20mL glass reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com