A manganese dioxide-doped barium-strontium niobate based glass ceramic energy-storing material and a preparing method thereof

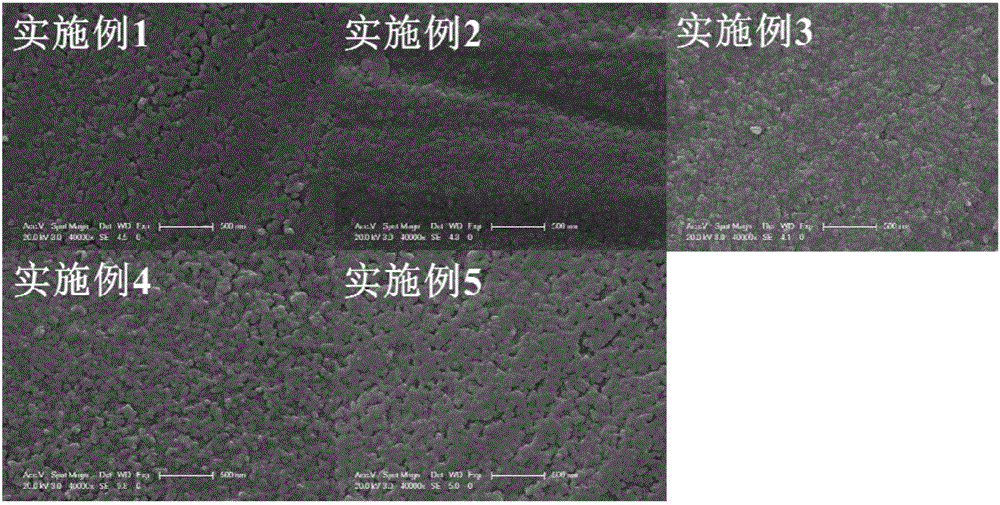

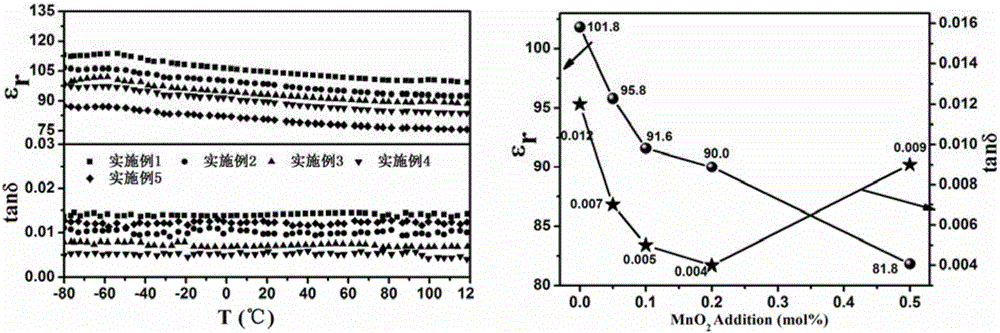

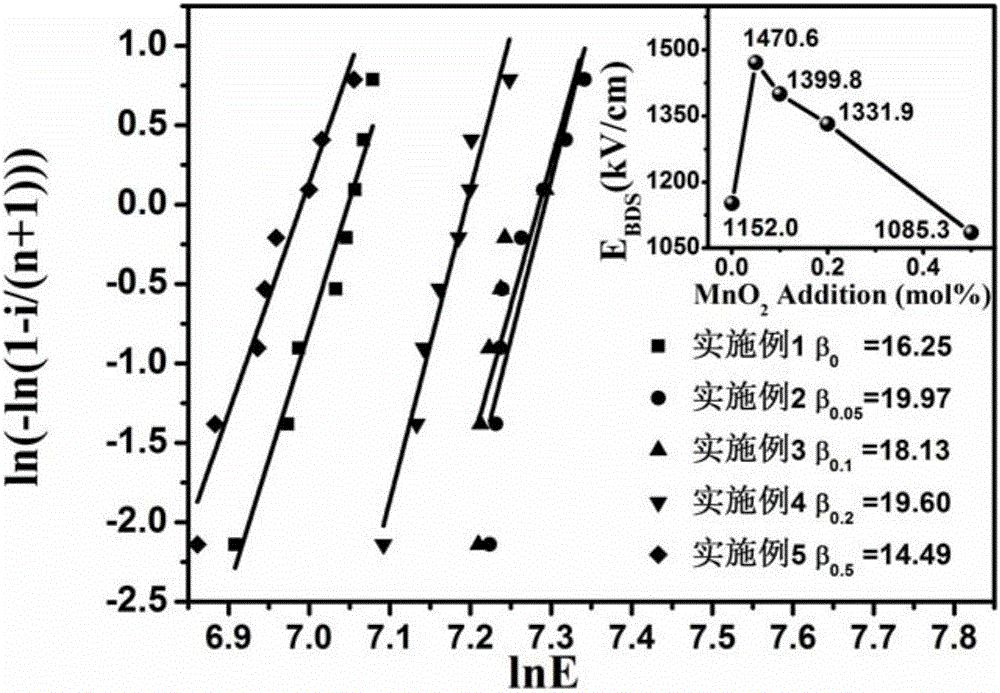

A strontium barium niobate-based energy storage material technology, which is applied in the field of manganese dioxide-doped strontium barium niobate-based glass ceramic energy storage materials and its preparation, can solve the problem of low charge-discharge conversion efficiency, no obvious reduction, microscopic Inhomogeneous structure and other problems, to achieve the effect of excellent machining performance, reduced grain agglomeration, and dense and uniform microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Manganese dioxide-doped barium strontium niobate-based glass ceramic material with high energy storage density, high energy conversion efficiency and low dielectric loss:

[0036] 1) BaCO with a purity greater than 99.0wt% 3 , SrCO 3 , Nb2O5, SiO 2 、Al 2 o 3 , B 2 o 3 , MnO 2 For raw material ingredients, the molar percentages of the above components are 20%, 20%, 20%, 33.5%, 5%, 1.5%, 0%. After ball mixing for 20 hours, dry and melt at 1550°C for 2 hours ;

[0037] 2) Pouring the high-temperature melt obtained in step 1) into a metal mold, annealing for stress relief at 650° C. for 7 hours, and then cutting to obtain glass flakes with a thickness of about 1.5 mm;

[0038] 3) The glass flakes prepared in step 2) are crystallized at 1100°C at a heating rate of 3°C / min, holding time for 3 hours, and controlled to crystallize at a cooling rate of 3°C / min to 850°C, and then cooled with the furnace to At room temperature, a manganese dioxide-doped barium strontium n...

Embodiment 2

[0041] Manganese dioxide-doped barium strontium niobate-based glass ceramic material with high energy storage density, high energy conversion efficiency and low dielectric loss:

[0042] 1) BaCO with a purity greater than 99.0wt% 3 , SrCO 3 , Nb2O5, SiO 2 、Al 2 o 3 , B 2 o 3 , MnO 2 For raw material ingredients, the molar percentages of the above components are 20%, 20%, 20%, 33.5%, 5%, 1.5%, 0.05%. After ball mixing for 20 hours, dry and melt at 1550°C for 2 hours ;

[0043] 2) Pouring the high-temperature melt obtained in step 1) into a metal mold, annealing for stress relief at 650° C. for 7 hours, and then cutting to obtain glass flakes with a thickness of about 1.5 mm;

[0044] 3) The glass flakes prepared in step 2) are crystallized at 1100°C at a heating rate of 3°C / min, holding time for 3 hours, and controlled to crystallize at a cooling rate of 3°C / min to 850°C, and then cooled with the furnace to At room temperature, a manganese dioxide-doped barium strontiu...

Embodiment 3

[0048] Manganese dioxide-doped barium strontium niobate-based glass ceramic material with high energy storage density, high energy conversion efficiency and low dielectric loss:

[0049] 1) BaCO with a purity greater than 99.0wt% 3 , SrCO 3 , Nb2O5, SiO 2 、Al 2 o 3 , B 2 o 3 , MnO 2 For raw material ingredients, the molar percentages of the above components are 20%, 20%, 20%, 33.5%, 5%, 1.5%, 0.1%. After ball mixing for 20 hours, dry and melt at 1550°C for 2 hours ;

[0050] 2) Pouring the high-temperature melt obtained in step 1) into a metal mold, annealing for stress relief at 650° C. for 7 hours, and then cutting to obtain glass flakes with a thickness of about 1.5 mm;

[0051] 3) The glass flakes prepared in step 2) are crystallized at 1100°C at a heating rate of 3°C / min, holding time for 3 hours, and controlled to crystallize at a cooling rate of 3°C / min to 850°C, and then cooled with the furnace to At room temperature, a manganese dioxide-doped barium strontium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com