Preparation method of adsorbent for heavy metal waste liquid treatment

A waste liquid treatment and adsorbent technology, applied in water/sewage treatment, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of limited adsorption and limited adsorption capacity, and achieve good synergy and low treatment cost The effect of reducing and shortening the processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

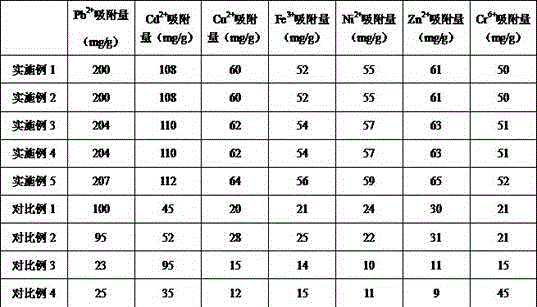

Examples

Embodiment 1

[0023] A preparation method for an adsorbent for heavy metal waste liquid treatment, comprising the steps of:

[0024] Mix pomelo peel and persimmon peel (mass ratio 1:1) and wash with water to obtain the mixture, then mix it with sodium hydroxide and water according to the mass ratio 1:0.1~0.2:1~2 for 6 hours , filtered to obtain the adsorbent, washed twice with water, then vacuum-dried at 60°C for 12 hours, crushed, sieved, and set aside.

[0025] The treatment method of the heavy metal waste liquid by the adsorbent is as follows: adjust the pH value of the heavy metal waste liquid to 6 with concentrated hydrochloric acid or concentrated ammonia water, add the obtained adsorbent, stir and mix, and let stand for 10 minutes; wherein, the adsorbent The mass volume ratio of heavy metal waste liquid is 1g:1L.

Embodiment 2

[0027] A preparation method for an adsorbent for heavy metal waste liquid treatment, comprising the steps of:

[0028] Mix pomelo peel and persimmon peel (mass ratio 1:2) and wash with water to obtain the mixture, then stir it with sodium hydroxide, potassium hydroxide or ammonium bicarbonate and water according to the mass ratio 1:0.2:2 Mix and react for 12 hours, filter to obtain the adsorbent, wash with water 3 times, then vacuum-dry at 80°C for 24 hours, crush, sieve, and set aside;

[0029] The treatment method of the heavy metal waste liquid by the adsorbent is: use concentrated hydrochloric acid or concentrated ammonia water to adjust the pH value of the heavy metal waste liquid to 7, add the obtained adsorbent, stir and mix, and let it stand for 15 minutes; wherein, the adsorbent The mass volume ratio of heavy metal waste liquid is 0.5g:1L.

Embodiment 3

[0031] A preparation method for an adsorbent for heavy metal waste liquid treatment, comprising the steps of:

[0032] Mix grapefruit peel and persimmon peel (mass ratio 1:1) and wash with water to obtain a mixture, then stir it with sodium hydroxide, potassium hydroxide or ammonium bicarbonate and water according to the mass ratio of 1:0.1:2 Mix and react for 6 hours, filter to obtain the adsorbent, wash with water for 3 times, then vacuum-dry at 60°C for 24 hours, crush, sieve, and set aside;

[0033] The treatment method of the heavy metal waste liquid by the adsorbent is as follows: adjust the pH value of the heavy metal waste liquid to 6 with concentrated hydrochloric acid or concentrated ammonia water, add the obtained adsorbent, stir and mix, and let stand for 15 minutes; wherein, the adsorbent The mass volume ratio of heavy metal waste liquid is 2g:1L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com