Preparation method of graphene nanoribbon

A graphene nanoribbon, carbon nanotube technology, applied in graphene nanoribbon, graphene, nanocarbon and other directions, can solve the problems of large randomness and uncertainty, high production cost and energy consumption, and high equipment requirements , to achieve the effect of low equipment requirements, complete layered structure, and extended application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The concrete steps of a kind of graphene nanoribbon preparation method are as follows:

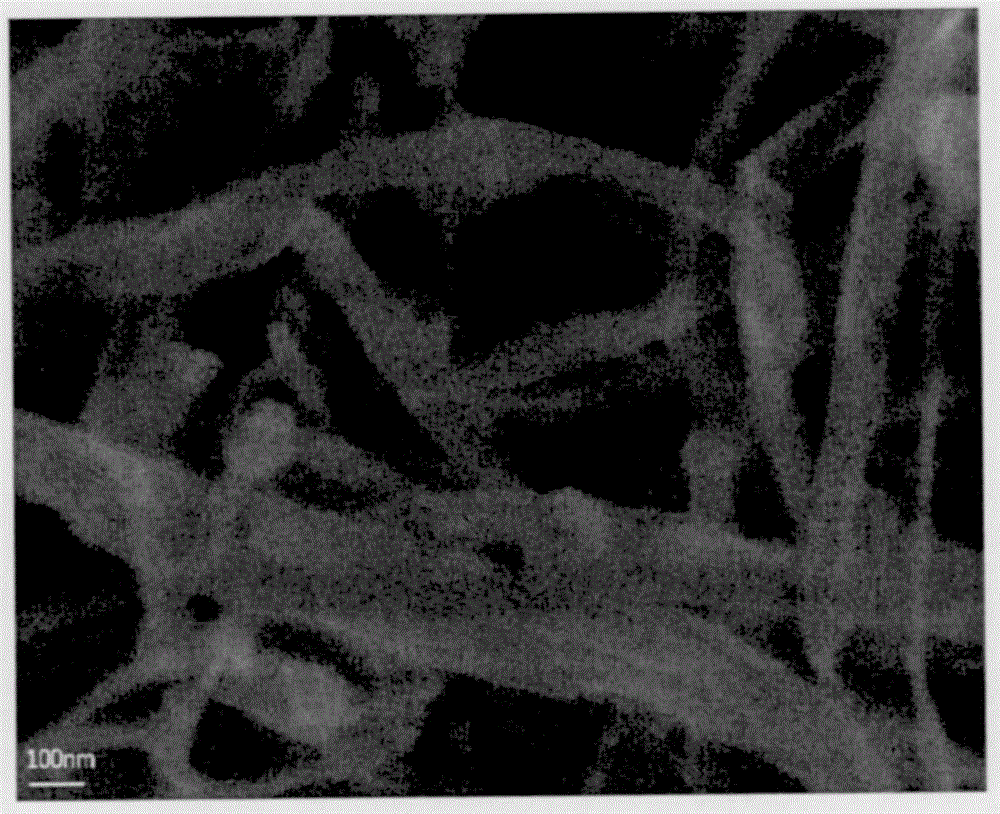

[0032] 1) Cutting carbon nanotubes by reduction method

[0033] Using multi-walled carbon nanotubes as raw materials (diameter ~ 100nm, length ~ 50μm, carbon content 95%), under the protection of high-purity inert argon atmosphere, according to the volume of ethylene glycol dimethyl ether organic solvent and carbon nanotubes Mass ratio 3000ml: 1g Weigh a certain amount of carbon nanotubes and add them to the ethylene glycol dimethyl ether organic solvent, then measure a certain amount of sodium potassium liquid according to the mass volume ratio of carbon nanotubes to sodium potassium liquid alloy 1g: 2ml Alloy (the mass ratio of sodium and potassium in the alloy is 1g: 2g) is added to the above mixture, and stirred at room temperature for 5 days to obtain mixture 1, then the mixture 1 is subjected to suction filtration, and the solid residue is collected, according to the mass volu...

Embodiment 2

[0039] The concrete steps of a kind of graphene nanoribbon preparation method are as follows:

[0040] A kind of preparation method of graphene nanobelt, with embodiment 1, wherein

[0041] In step (1), the double-walled carbon nanotubes are used as raw materials (diameter ~ 50nm, length ~ 30 μm, carbon content 97%), the inert atmosphere is a high-purity helium atmosphere, and the organic solvent is diethylene glycol dimethyl ether , in the liquid sodium-potassium alloy, the mass ratio of sodium and potassium is 1g: 5g, the mass of carbon nanotubes: the volume of organic solvent: the ratio of the volume of sodium-potassium liquid alloy is 1g: 1500ml: 4ml, stirring at room temperature for 3 days, the mixture 1 is prepared. The solid residue was cleaned according to the mass volume ratio of the cleaning solution: 1 g: 200 ml. The order of the cleaning solution is to wash twice with tetrahydrofuran, twice with isopropanol, and twice with deionized water.

[0042] In the 2nd ste...

Embodiment 3

[0045] The concrete steps of a kind of graphene nanoribbon preparation method are as follows:

[0046] In the (1) step, the single-walled carbon nanotubes are used as raw materials (diameter ~ 2nm, length ~ 1 μm, carbon content 99%), the inert atmosphere is a high-purity nitrogen atmosphere, and the organic solvent is triethylene glycol dimethyl ether, In the liquid sodium-potassium alloy, the mass ratio of sodium to potassium is 1g:10g, the mass of carbon nanotubes:volume of organic solvent:volume of sodium-potassium liquid alloy is 1g:500ml:10ml, and stirred at room temperature for 1 day to prepare mixture 1. The solid residue was cleaned according to the mass volume ratio of the cleaning solution: 1 g: 300 ml. The order of the cleaning solution was THF 3 times, isopropanol 3 times, and deionized water 3 times.

[0047] In the (2) step, the oxidizing acid is dilute nitric acid, and the stirring time is 1h. After adding the oxidizing agent, stir at room temperature for 1h. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com