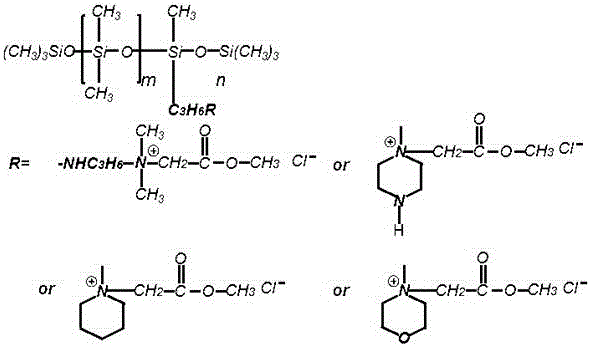

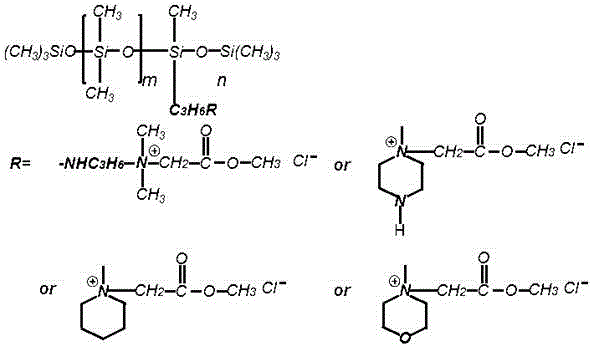

Low-yellowing quaternary ammonium type hydrophilic amino-modified silicone oil emulsion and preparation method thereof

A technology of silicone oil emulsion and amino silicone oil, applied in the directions of improved hand-feeling fibers, textiles and papermaking, fiber processing, etc., can solve the problems of reducing the yellowing of fabric finishing agents, not improving the hydrophilicity, affecting the hydrophilic performance, etc., and achieving excellent Hydrophilic, smooth feel, color reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of low-yellowing amino silicone oil: mix 660 grams of α, ω-hydroxy polydimethylsiloxane (silicone linear body) with 25 grams of N-(γ'-dimethylaminopropyl)-γ - Aminopropylmethyldimethoxysilane, 0.2 grams of 30% aqueous sodium hydroxide solution, 5 grams of hexamethyldisiloxane, reacted at 95 ° C for 3 hours under a vacuum of 100 mbar, neutralized with acetic acid to obtain amino silicone oil.

[0032] (2) Preparation of low-yellowing quaternized amino silicone oil: add 690 grams of amino silicone oil and 12 grams of methyl chloroacetate to 210 grams of isopropanol solution and mix uniformly, react at 80° C. for 8 hours to obtain low Yellowing quaternized amino silicone oil.

[0033] (3) Preparation of low-yellowing quaternary ammonium type hydrophilic amino silicone oil emulsion: 11.6 grams of acid are added to 912 grams of quaternized amino silicone oil, and at 25 ° C under stirring conditions, 1250 grams of deionized water is added dropwise and stirred...

Embodiment 2

[0035] (1) Preparation of low-yellowing amino silicone oil: mix 660 grams of α, ω-hydroxy polydimethylsiloxane (organic silicon linear body) with 25 grams of γ-piperazinylpropylmethyldimethoxysilane , 0.2 g of 30% aqueous sodium hydroxide solution and 5 g of hexamethyldisiloxane were reacted at 95° C. for 3 hours under a vacuum of 100 mbar, and neutralized with acetic acid to obtain amino silicone oil.

[0036] (2) Preparation of low-yellowing quaternized amino silicone oil: add 690 grams of amino silicone oil and 12.9 grams of methyl chloroacetate to 210 grams of isopropanol solution and mix uniformly, react for 8 hours at 80° C. to obtain low Yellowing quaternized amino silicone oil.

[0037] (3) Preparation of low-yellowing quaternary ammonium type hydrophilic amino silicone oil emulsion: 11.6 grams of acid are added to 912 grams of quaternized amino silicone oil, and at 25 ° C under stirring conditions, 1250 grams of deionized water is added dropwise and stirred After 1.5...

Embodiment 3

[0039] (1) Preparation of low-yellowing amino silicone oil: mix 660 grams of α, ω-hydroxypolydimethylsiloxane (organic silicon linear body) with 25 grams of γ-piperidylpropylmethyldimethoxysilane , 0.2 g of 30% aqueous sodium hydroxide solution and 5 g of hexamethyldisiloxane were reacted at 95° C. for 3 hours under a vacuum of 100 mbar, and neutralized with acetic acid to obtain amino silicone oil.

[0040] (2) Preparation of low-yellowing quaternized amino silicone oil: add 690 grams of amino silicone oil and 12.9 grams of methyl chloroacetate to 210 grams of isopropanol solution and mix uniformly, react for 8 hours at 80° C. to obtain low Yellowing quaternized amino silicone oil.

[0041] (3) Preparation of low-yellowing quaternary ammonium type hydrophilic amino silicone oil emulsion: 11.6 grams of acid are added to 912 grams of quaternized amino silicone oil, and at 25 ° C under stirring conditions, 1250 grams of deionized water is added dropwise and stirred After 1.5 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com