Anti-sagging single-component polyurea coating and preparation method thereof

A single-component, anti-sagging technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of large amount of anti-sagging additives, increased viscosity of the coating system, and small effective production volume. Good dispersibility, good thixotropy, and excellent thixotropic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This example provides a kind of preparation method of hyperbranched polyurea anti-sagging agent, implements as follows:

[0039] Feed the diisocyanate monomer IPDI and butanol at a molar ratio of 2.2:1, and mix and react for 3 hours under nitrogen protection at a temperature of 75°C to prepare a monoisocyanate-terminated prepolymer;

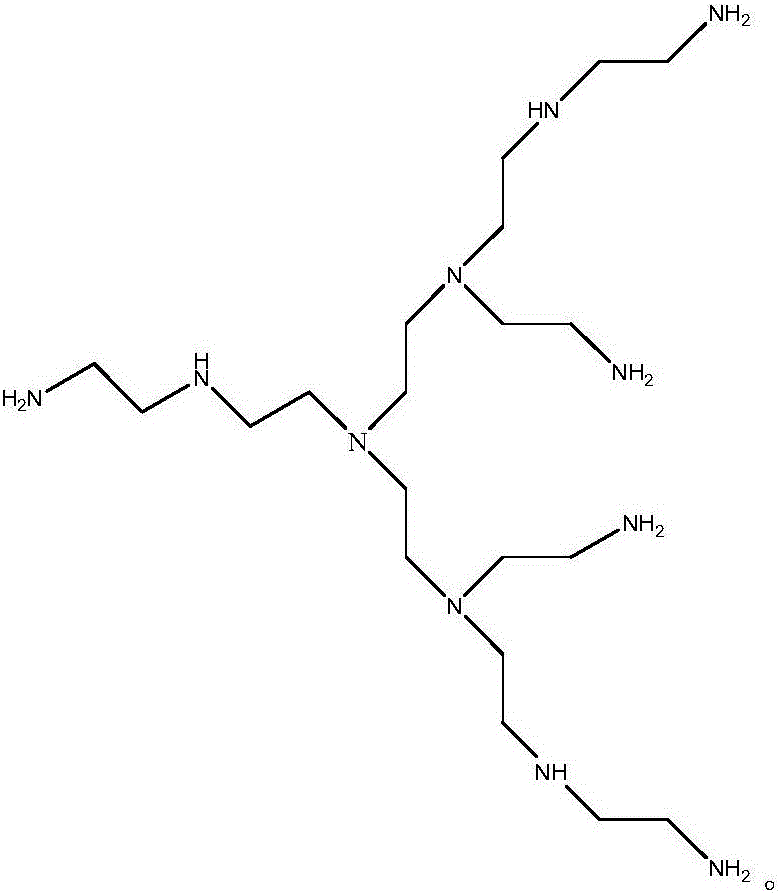

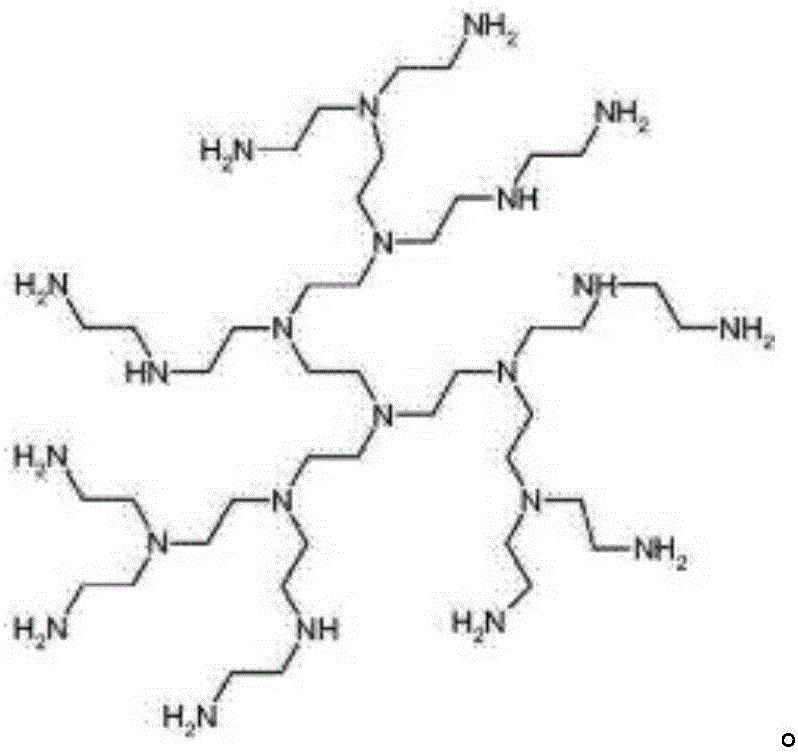

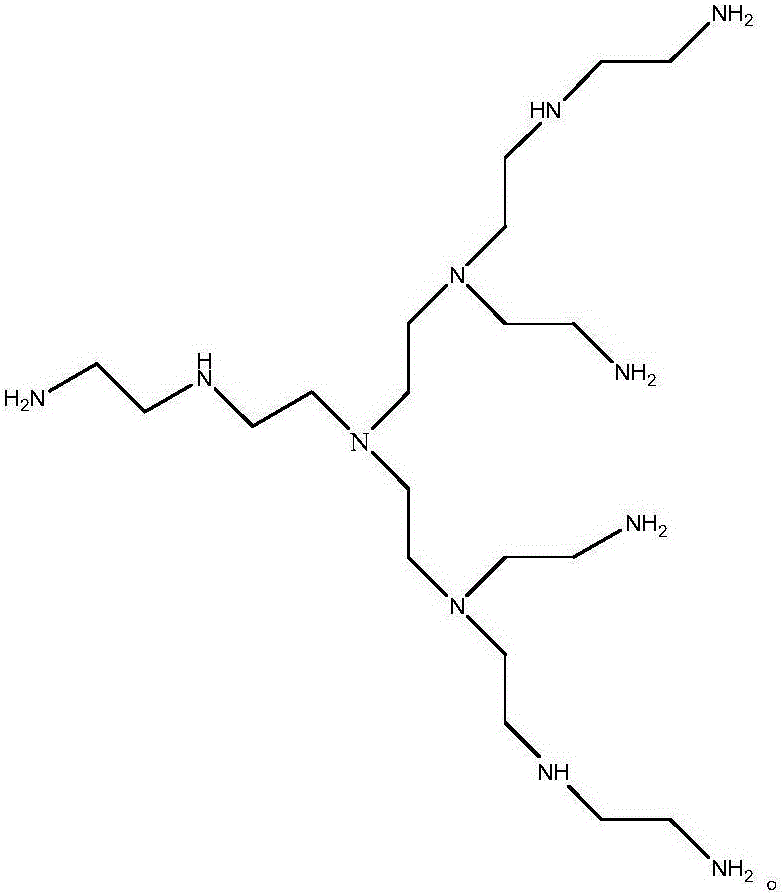

[0040] Dissolve hyperbranched polyethyleneimine in a mixed solvent of dimethylformamide and N-methylpyrrolidone (volume ratio 1:1), add monoisocyanate-terminated prepolymer, and the molar ratio of isocyanate groups to amino protons is 1.1 : 1, mixed reaction 1.5h, reaction temperature 30-40 ℃, obtain hyperbranched polyurea anti-sagging agent.

Embodiment 2

[0042] This example provides a kind of preparation method of hyperbranched polyurea anti-sagging agent, implements as follows:

[0043] Feed the diisocyanate monomer TDI and hexyl alcohol according to the molar ratio of 2.2:1, and mix and react for 2.5 hours under the protection of nitrogen and at a temperature of 80°C to prepare a monoisocyanate-terminated prepolymer;

[0044] Dissolve hyperbranched polyethyleneimine in a mixed solvent of dimethylformamide and N-methylpyrrolidone (volume ratio 1:1), add monoisocyanate-terminated prepolymer, and the molar ratio of isocyanate groups to amino protons is 1.1 : 1, mixed reaction 2h, reaction temperature 30-40 ℃, namely the hyperbranched polyurea anti-sagging agent.

Embodiment 3

[0046] This example provides a kind of anti-sag one-component polyurea coating, and its raw material formula is: diphenylmethane diisocyanate TDI (BASF T-80) 20 parts, polyether polyol (2471, the United States pottery) Shi Chemical) 55 parts, chain extender 10 parts (FT-6270, Suzhou Feite Brothers New Material Technology Co., Ltd.), gray color paste 5 parts (Clariant), oxazolidine latent curing agent (MS-201, Qingdao Hengke New Material Technology Co., Ltd.) 3 parts, organic bismuth catalyst (Shanghai Hemu Chemical Co., Ltd.) 0.5 part, defoamer (BYK-1790, Bi Ke, Germany) 0.3 part and hyperbranched polyurea anti-sagging agent (embodiment 1 Prepared) 1 part.

[0047] The preparation method of anti-sagging one-component polyurea coating is as follows:

[0048] Step 1: In the closed reaction kettle, add 2471 polyether and color paste, stir and raise the temperature, control the temperature at 100-120°C, turn on the vacuum pump to draw negative pressure, control the pressure below...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com