Highly doped rare earth up-conversion fluorescent nano material and preparation method thereof

A technology for up-conversion of fluorescent nanomaterials and rare earths, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve problems such as reduction of luminous intensity, practicality and universality limitations, quenching, etc., to increase doping concentration and improve quenching The effect of killing concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides a preparation method of the above-mentioned highly doped rare earth up-conversion fluorescent nano material, which includes the following steps:

[0035] A) Preparation of up-conversion nanoparticles doped with rare earth ions;

[0036] B) Shell-coating the nanoparticles obtained in step A).

[0037] The preparation of the above-mentioned up-conversion nanoparticles doped with rare earth ions is a technique well known to those skilled in the art. Specifically, the chloride-oleic acid precursor method or the trifluoroacetate decomposition method can be used.

[0038] Then, the prepared nanoparticles are added to the inert shell material, and the temperature is increased from 300°C to 330°C to form nanoparticles with a core-shell structure.

[0039] Take NaYF 4 Inert shell as an example,

[0040] The above step B) is specifically: adding YCl 3 .6H 2 O powder is dissolved in the mixed solution of oleic acid and 1-octadecene, and then mixed with the...

Embodiment 1

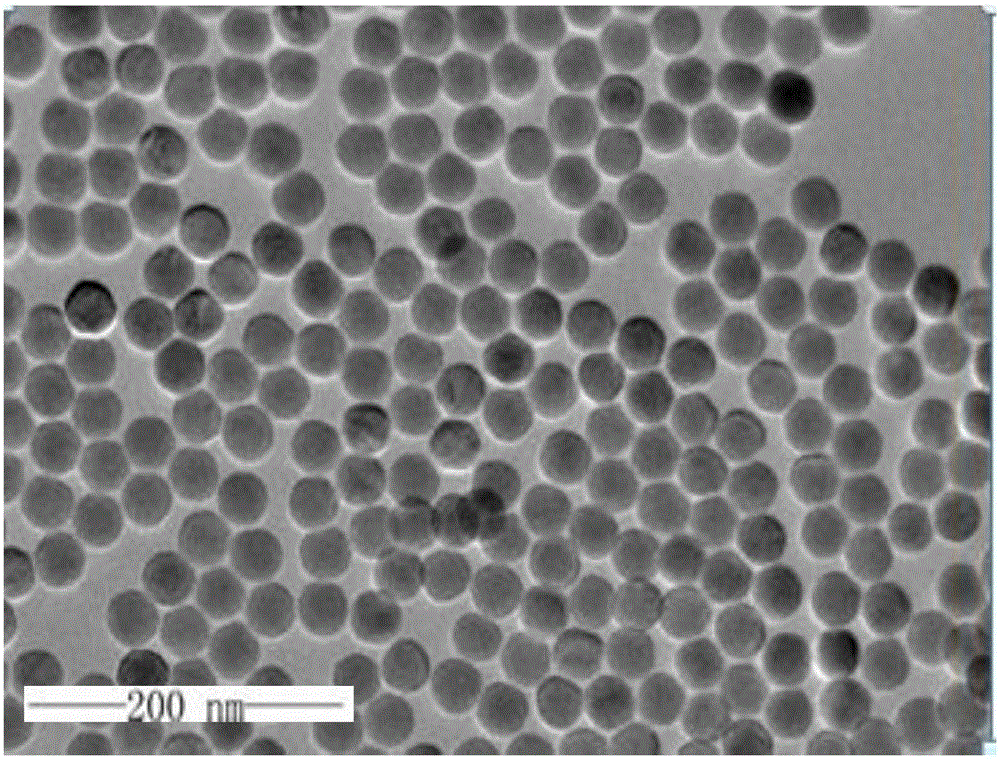

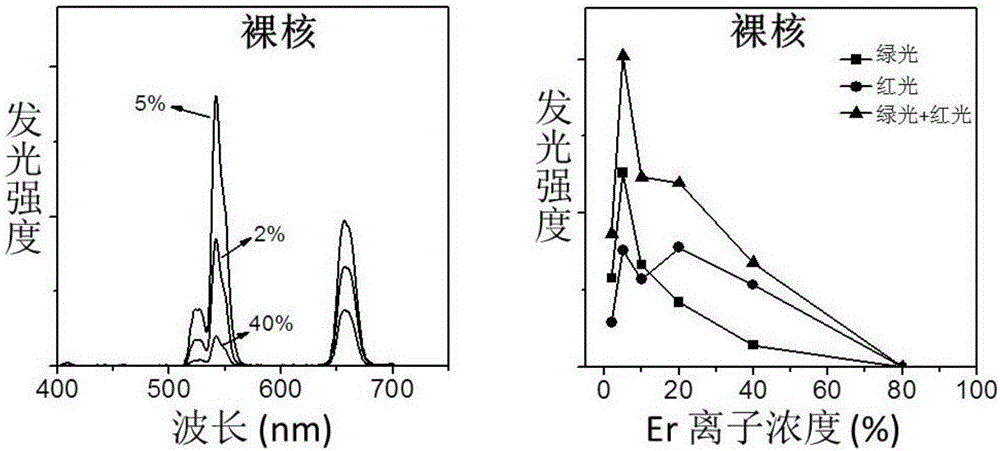

[0046] Er single doped 3+ NaYF 4 Preparation of the naked core of nanoparticles: ErCl in a certain proportion according to the doping concentration 3 ·6H 2 O and YCl 3 ·6H 2 O (the two are 1 millimoles, doped with Er 3+ Concentrations are 5%, 10%, 20%, 40%, 80%) The powder is placed in a 100ml three-necked flask, 6ml oleic acid and 15ml 1-octadecene liquid are added, and the temperature is raised to 155℃ under the protection of inert gas After dissolving completely, let it cool to room temperature naturally, and then drip into 6ml containing 100mg NaOH and 148mg NH 4 The methanol solution of F is fully stirred and then the temperature is raised to 70°C to remove the methanol, and then the temperature is gradually raised to 300-330°C under the protection of inert gas, the reaction is carried out for 90 minutes, and then it is naturally cooled to room temperature. Wash the resulting solution three times with acetone and ethanol by centrifugation, and disperse the remaining solid (a...

Embodiment 2

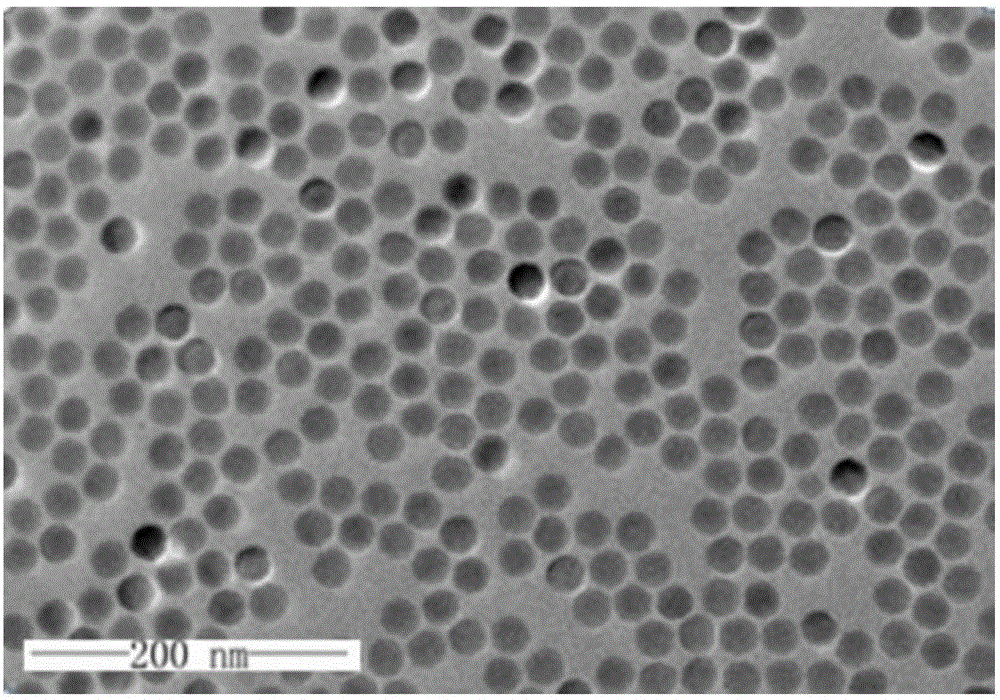

[0054] The preparation method of homogeneous core-shell structure nanoparticles: 152mg YCl 3 ·6H 2 Put the O powder in a 100ml three-necked flask, add 6ml of oleic acid and 15ml of 1-octadecene liquid, under the protection of inert gas, raise the temperature to 150℃ to make it completely dissolved, then cool to room temperature naturally, and then drop 4ml containing 75mg Er-doped prepared in Example 1 3+ NaYF 4 Naked core nanoparticles (Er doped 3+ Concentrations of 5%, 10%, 20%, 40%, 80%) in cyclohexane solution, slowly increase the temperature to 80°C to remove the cyclohexane, then cool to room temperature, drop 3ml containing 50mg NaOH and 74mg NH 4 The methanol solution of F is heated to 70°C to remove the methanol, and then gradually heated to 300-330°C under the protection of inert gas, reacted for 60 minutes, and then naturally cooled to room temperature. Wash the resulting solution three times with acetone and ethanol by centrifugation, and disperse the remaining solid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com