Method for secondarily reforming tar by utilizing in-situ composite semicoke made from high alkaline coal and biomass

A technology for biomass raw materials and high alkali coal, which is applied in the fields of biofuels, chemical instruments and methods, and preparation of liquid hydrocarbon mixtures, etc. The effect of high activity and partial energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0031] 1) Sample pretreatment: 20-30 mesh and 60-100 mesh dry and crushed pine wood chips and Xinjiang high-alkali coal are screened out, and then the two are evenly mixed, and the mass of Xinjiang high-alkali coal in the mixed sample is The ratio is 20%;

[0032] 2) Catalyst (composite semi-coke) preparation: 2g of the mixed sample prepared in 1) was added to the lower layer of the double-layer pyrolysis fixed-bed reactor, and the nitrogen flow rate was 200ml / min, the heating rate was 20℃ / min, Pyrolysis is carried out under the condition that the final temperature of the solution is 800°C to prepare the catalyst required for subsequent pyrolysis;

[0033] 3) Secondary catalytic reforming of tar: After the pyrolysis in 2), add 4g of prepared pine sawdust to the upper layer to carry out the catalytic reforming experiment of tar, and collect tar and pyrolysis synthesis gas during the pyrolysis process.

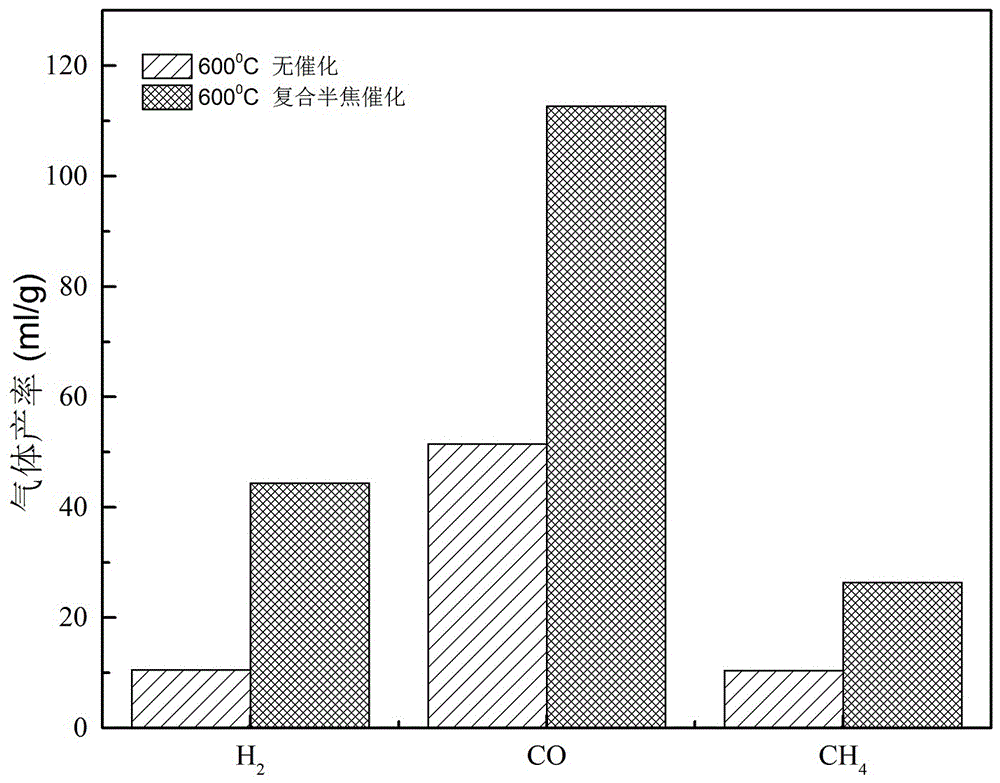

[0034] The pyrolysis temperature of the upper layer is 600°C, and the pyro...

Embodiment example 2

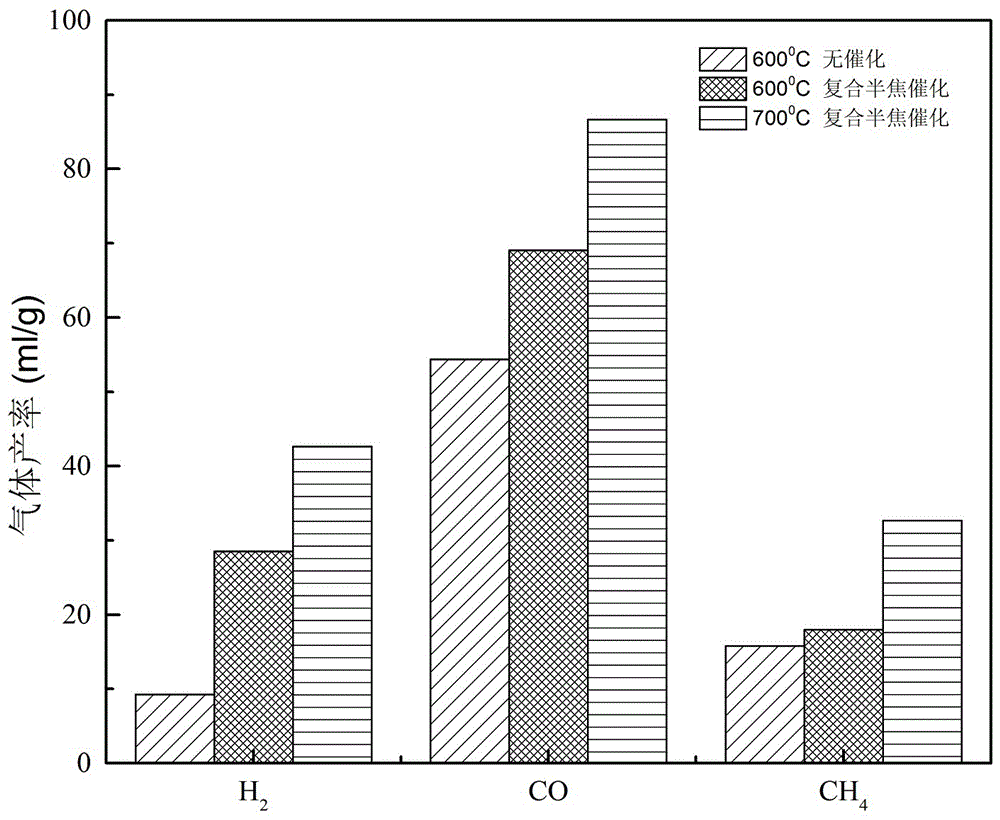

[0037] Similar to Example 1, the pyrolysis raw material in the upper layer is changed to corn cob, and other operations are the same as Example 1. Compared with no catalysis, the tar yield decreased by 40%, and the combustible gas components increased. The specific experimental results are as follows figure 2 shown.

Embodiment example 3

[0039] Similar to Example 1, the pyrolysis raw material of the upper layer was changed to corncob, and the pyrolysis temperature of the lower layer was changed to 700° C., and other operations were the same as Example 1. Compared with no catalysis, the tar conversion rate is reduced by 40%. The experimental results are as follows figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com