Composite binder for lithium battery and application of composite binder

A binder and lithium battery technology, which is applied in the direction of lithium batteries, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problems of poor contact, fast drop rate of discharge platform, and increased battery contact resistance, so as to reduce side reactions , Improve storage life, slow down the effect of pulse ability decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

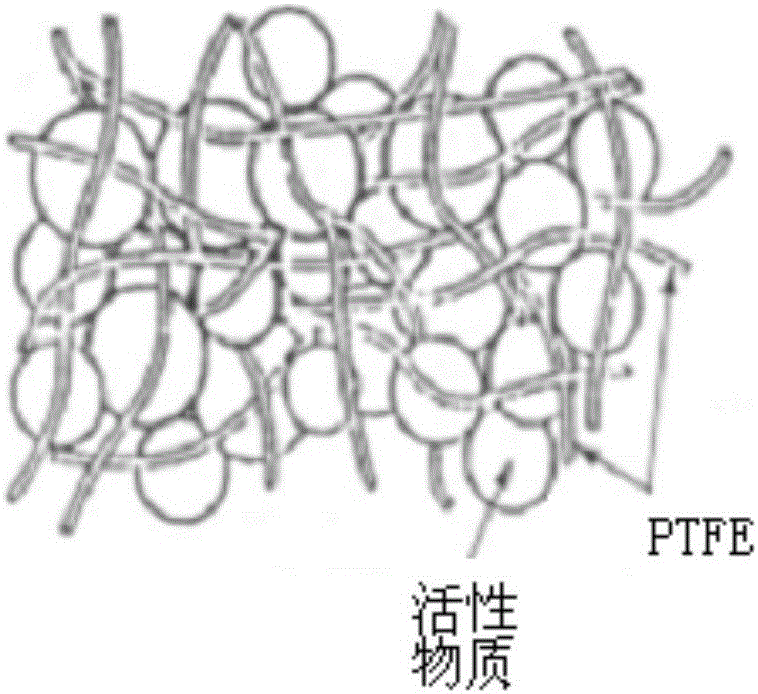

[0037] (1) 88.5wt% MnO 2 Fully mixed with 5wt% Ketjen black, then fully mixed with 6% polytetrafluoroethylene and 0.5% CMC, and dried at 160°C for fiber drying;

[0038] (2) After granulating the fibrous powder, press it into a lithium battery positive electrode sheet, the weight of the positive electrode is 0.93-1.00g, and then bake it in an oven at 200°C for 12 hours;

[0039] (3) The positive electrode obtained in step (2), the negative electrode metal lithium, the electrolyte (ethylene glycol dimethyl ether and propylene carbonate solution of 1mol / L lithium perchlorate) and the separator are assembled into a lithium battery.

Embodiment 2

[0041] (1) 86wt% MnO 2 Fully mixed with 4.5wt% Ketjen Black, then fully mixed with 7% polytetrafluoroethylene, 0.5% CMC and 2% acrylonitrile multi-polymer, and dried at a temperature of 165°C;

[0042] (2) After granulating the fibrous powder, press it into a lithium battery positive electrode sheet, the weight of the positive electrode is 0.93-1.00g, and then bake it in an oven at 200°C for 13 hours;

[0043] (3) The positive electrode obtained in step (2), the negative electrode metal lithium, the electrolyte (ethylene glycol dimethyl ether and propylene carbonate solution of 1mol / L lithium perchlorate) and the separator are assembled into a lithium battery.

Embodiment 3

[0045] (1) 91wt% MnO 2 Fully mixed with 3wt% acetylene black, then fully mixed with 4% polytetrafluoroethylene and 2% acrylonitrile multi-polymer, and dried at 168°C for fibril drying;

[0046] (2) After granulating the fibrous powder, press it into a lithium battery positive electrode sheet, the weight of the positive electrode is 0.93-1.00g, and then bake it in an oven at 200°C for 14 hours;

[0047](3) The positive electrode obtained in step (2), the negative electrode metal lithium, the electrolyte (ethylene glycol dimethyl ether and propylene carbonate solution of 1mol / L lithium perchlorate) and the separator are assembled into a lithium battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com