A kind of lithium battery composite binder and its application

A binder and conductive agent technology, which is applied in the field of lithium battery composite binders, can solve the problems of increased battery contact resistance, poor contact, and fast drop rate of the discharge platform, so as to slow down the decline of pulse ability and reduce side reactions , Improve the effect of storage life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

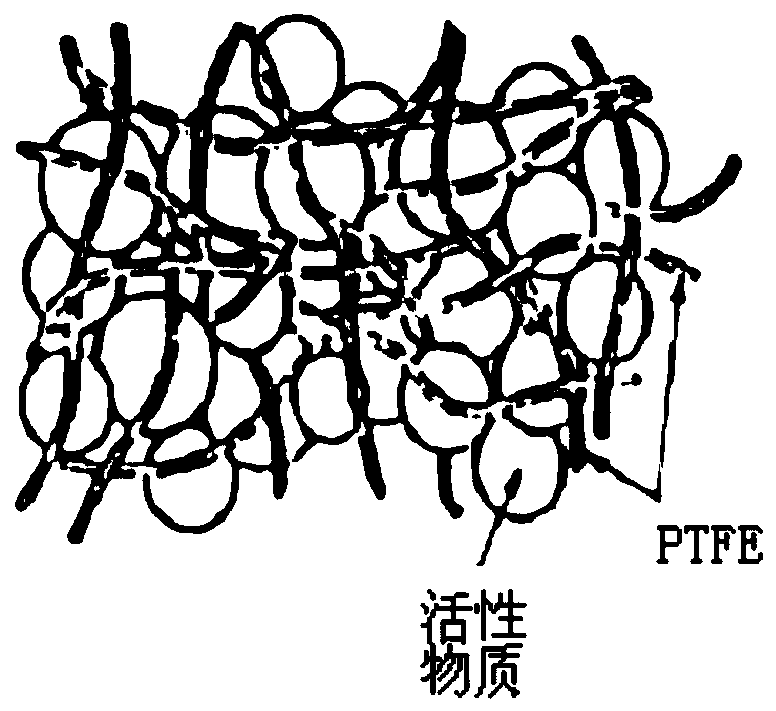

Method used

Image

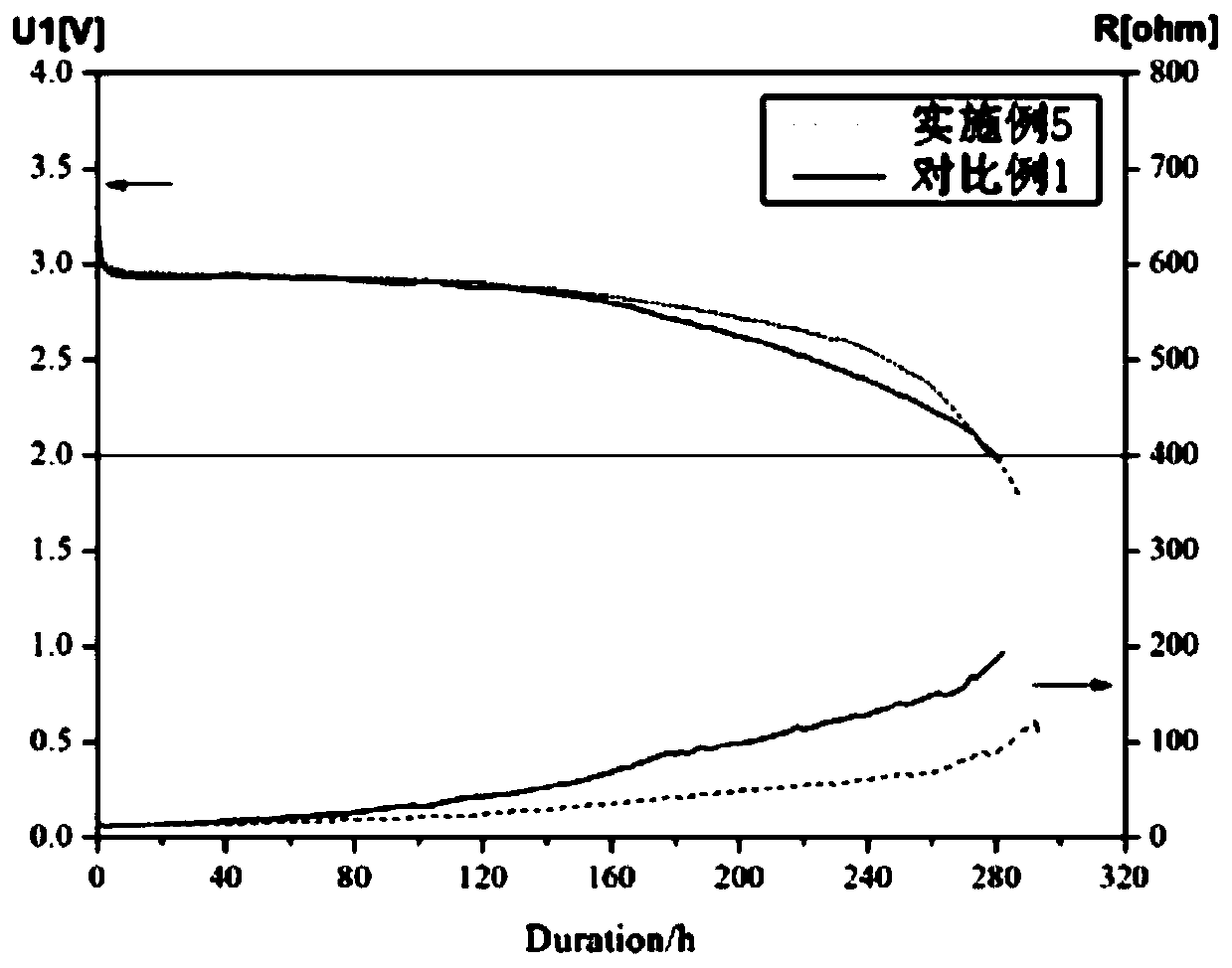

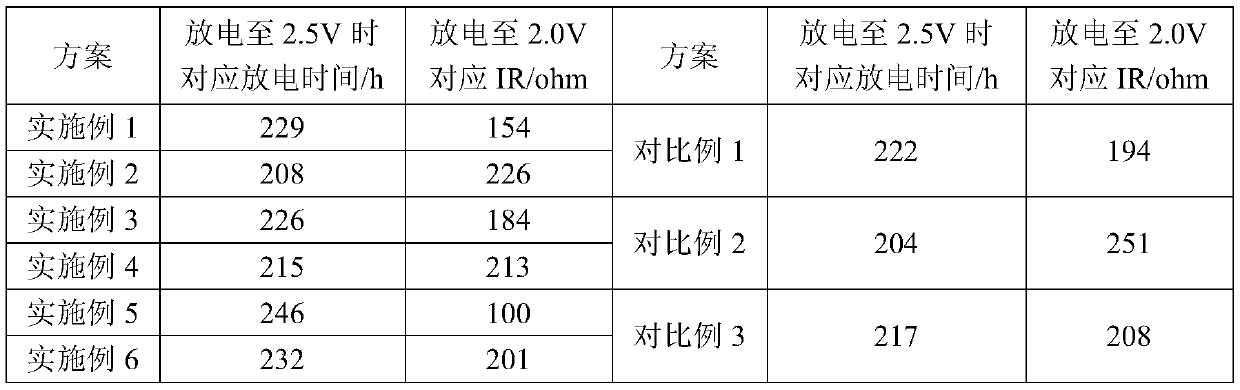

Examples

Embodiment 1

[0037] (1) 88.5wt% MnO 2 Fully mixed with 5wt% Ketjen black, then fully mixed with 6% polytetrafluoroethylene and 0.5% CMC, and dried at 160°C for fiber drying;

[0038] (2) After granulating the fibrous powder, press it into a lithium battery positive electrode sheet, the weight of the positive electrode is 0.93-1.00g, and then bake it in an oven at 200°C for 12 hours;

[0039] (3) The positive electrode obtained in step (2), the negative electrode metal lithium, the electrolyte (ethylene glycol dimethyl ether and propylene carbonate solution of 1mol / L lithium perchlorate) and the separator are assembled into a lithium battery.

Embodiment 2

[0041] (1) 86wt% MnO 2 Fully mixed with 4.5wt% Ketjen Black, then fully mixed with 7% polytetrafluoroethylene, 0.5% CMC and 2% acrylonitrile multi-polymer, and dried at a temperature of 165°C;

[0042] (2) After granulating the fibrous powder, press it into a lithium battery positive electrode sheet, the weight of the positive electrode is 0.93-1.00g, and then bake it in an oven at 200°C for 13 hours;

[0043] (3) The positive electrode obtained in step (2), the negative electrode metal lithium, the electrolyte (ethylene glycol dimethyl ether and propylene carbonate solution of 1mol / L lithium perchlorate) and the separator are assembled into a lithium battery.

Embodiment 3

[0045] (1) 91wt% MnO 2 Fully mixed with 3wt% acetylene black, then fully mixed with 4% polytetrafluoroethylene and 2% acrylonitrile multi-polymer, and dried at 168°C for fibril drying;

[0046] (2) After granulating the fibrous powder, press it into a lithium battery positive electrode sheet, the weight of the positive electrode is 0.93-1.00g, and then bake it in an oven at 200°C for 14 hours;

[0047](3) The positive electrode obtained in step (2), the negative electrode metal lithium, the electrolyte (ethylene glycol dimethyl ether and propylene carbonate solution of 1mol / L lithium perchlorate) and the separator are assembled into a lithium battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com