Method and device for preparing high-purity silicon monoxide by medium-frequency induction heating way

An induction heating equipment, induction heating technology, applied in the direction of silicon oxide, chemical instruments and methods, pressure vessels used in chemical processes, etc. Equipment can not be effectively controlled and other problems, to achieve the effect of continuous and stable equipment, stable equipment, and low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

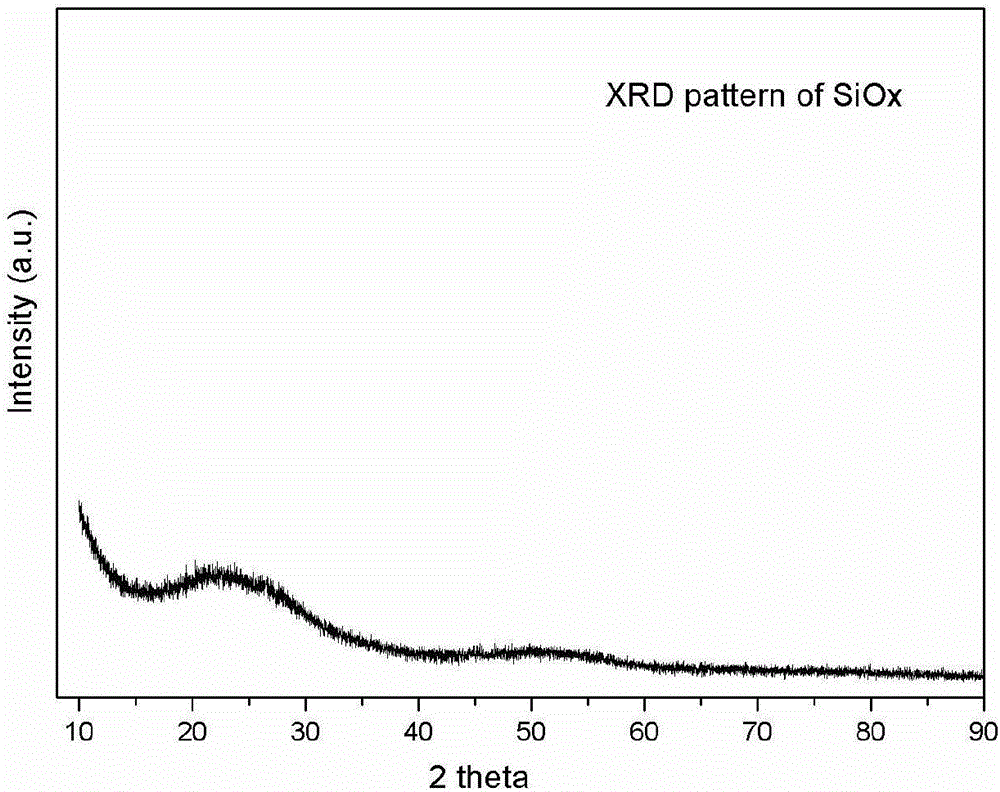

Embodiment 1

[0041] A method for preparing high-purity silicon oxide by means of medium-frequency induction heating, characterized in that the following preparation method is adopted:

[0042] 1. Raw material preparation: high-purity silicon with a content of >99.5wt% and silicon dioxide with a content >99.5wt% are mixed in a weight ratio of 1:1, pressed into a cake shape by a tablet press, and then dehydrated;

[0043] 2. Intermediate frequency induction heating: Put the cake-shaped mixed raw materials into the graphite crucible of intermediate frequency induction heating equipment, heat to 1200-2000°C under vacuum conditions, and keep the temperature constant for 3-5 hours to make the raw materials react and gradually sublimate; the intermediate frequency induction heating equipment The collector in introduces the sublimation gas into the cavity of the collector;

[0044] 3. Cooling to obtain the finished product: After 8-10 hours of constant temperature, the material is cooled to room t...

Embodiment 2

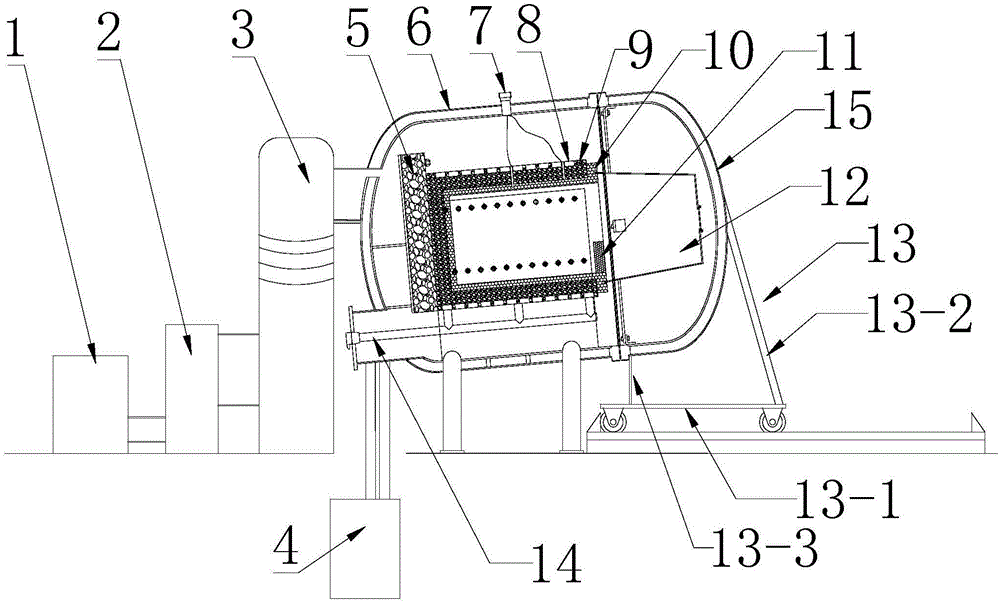

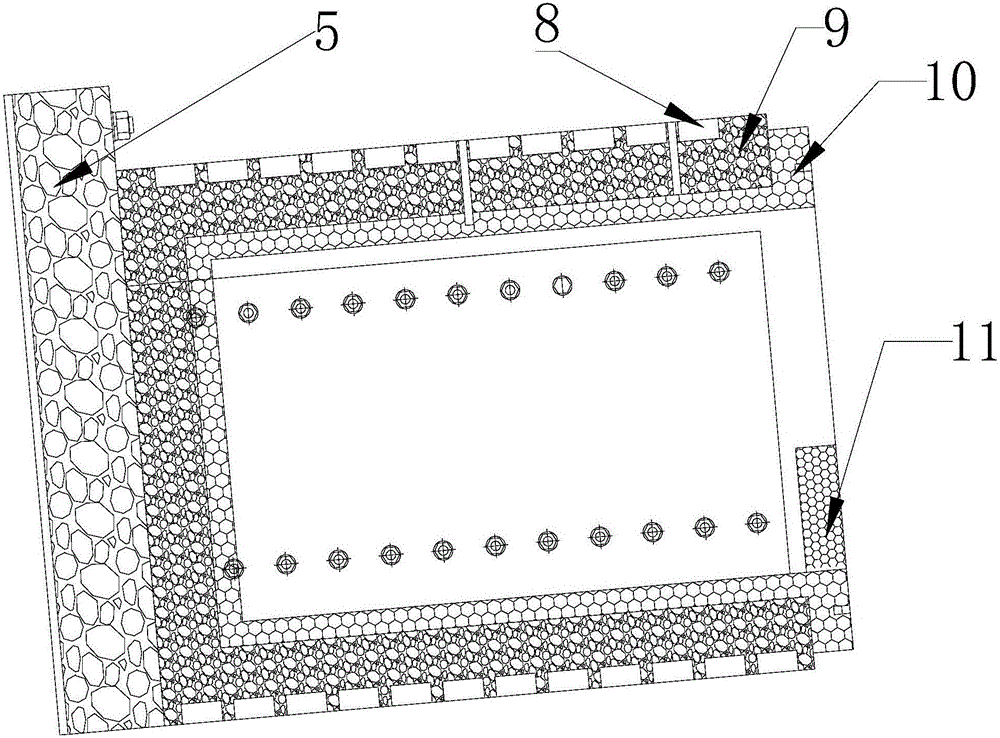

[0054] see figure 2 and image 3 , this example is the intermediate frequency induction heating equipment matched with the preparation method in Example 1, comprising a vacuum furnace shell 6, an induction coil 8, a thermal insulation layer 9, a graphite crucible 10, a collector, a furnace cover 15, and a water cooling system 14 , an intermediate frequency power supply 4, an intermediate frequency feeder 5, a vacuum pumping system, and a temperature measuring system, characterized in that the included angle between the central axis of the vacuum furnace shell 6 and the installation ground of the vacuum furnace shell 6 is 1 to 10 °; At least the open end side of the graphite crucible 10 located at the lower part of the central axis of the graphite crucible 10 is provided with a graphite baffle 11; the end face of the open end of the graphite crucible 10 is covered with a collector 12, and the collector 12 is a round table Cylindrical, and the diameter of the open end of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com