Preparation method of multifunctional nanocluster

A nano-cluster and multi-functional technology, which is applied in the field of preparation of multi-functional nano-clusters, can solve the problems of being difficult to disperse evenly and affecting the effect of α-ZrP on polymer flame retardancy and improving mechanical properties, achieving The effect of good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

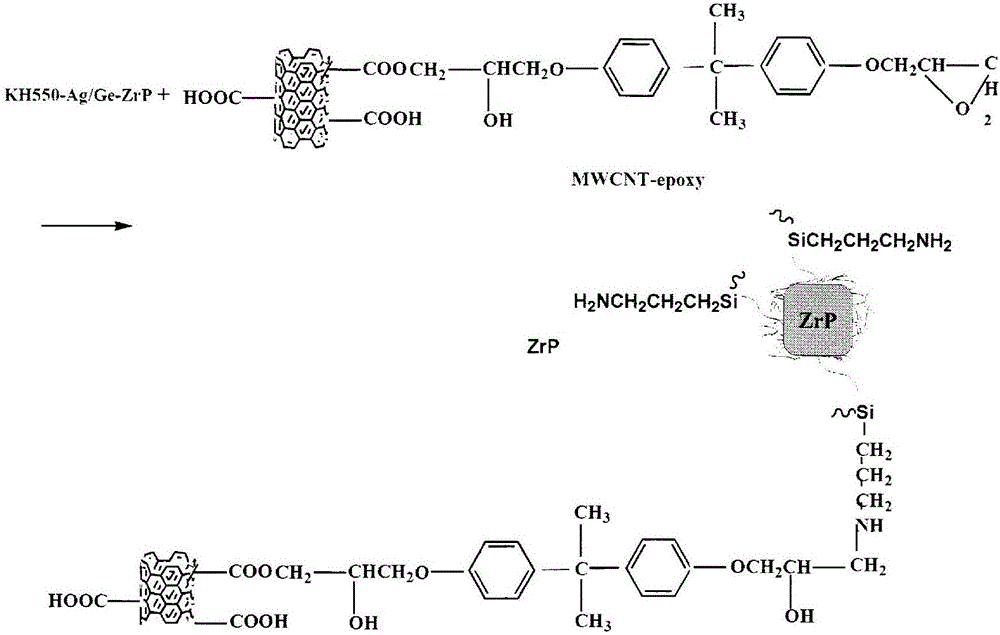

[0029] The steps of the preparation method of the multifunctional nano-cluster of the present invention are as follows:

[0030] 1) Disperse α-ZrP in the solvent. The surface of α-ZrP contains a large number of hydroxyl groups, which is highly hydrophilic and can be well dispersed in the solvent. The dispersion of α-ZrP can be promoted by ultrasound;

[0031] 2) Add metal salt solution for ion exchange reaction, α-ZrP has high ion exchange capacity, and functional metal ions can easily enter α-ZrP to form functional α-ZrP;

[0032] 3) Then add the silane coupling agent dropwise to continue the reaction. The siloxane group in the silane coupling agent will be hydrolyzed when it encounters water to form a highly reactive silanol bond Si-OH. Si-OH can be combined with α-ZrP sheet The dehydration and condensation reaction of P-OH on the surface generates a P-O-Si covalent bond with high thermal stability on the surface of the α-ZrP sheet. At the same time, because the silane coupl...

Embodiment 1

[0039] according to figure 1 As shown in the process, the steps of the preparation method of multifunctional nanoclusters are:

[0040] 1) Disperse α-ZrP in tetrahydrofuran solution with ultrasonic and mechanical stirring at room temperature, ultrasonic power is 50W, time is 20min; mechanical stirring speed is 200r / min, time is 20min, and the concentration of α-ZrP after dispersion is 0.05g / ml;

[0041]2) adding copper sulfate for ion exchange reaction, the molar ratio of copper sulfate to α-ZrP is 1:10, and the reaction time of adding copper sulfate is 6h;

[0042] 3) Add dropwise silane coupling agent KH550 to continue the reaction; the mass ratio of the amount of KH550 added to α-ZrP is 0.5:1; the rate of addition is 0.1ml / min; the time for continuing the reaction is 3h;

[0043] 4) adding nitric acid with a mass fraction of 80% to treat the multi-walled carbon nanotubes; the reaction temperature is 80° C., and the reaction time is 12 hours.

[0044] 5) Add E51 to modify...

Embodiment 2

[0048] according to figure 1 As shown in the process, the steps of the preparation method of multifunctional nanoclusters are:

[0049] 1) Disperse α-ZrP in chloroform with ultrasonic and mechanical stirring at room temperature, the ultrasonic power is 90W, and the time is 50min; the speed of mechanical stirring is 800r / min, and the time is 50min. Concentration is 0.2g / ml;

[0050] 2) adding silver nitrate for ion exchange reaction, the molar ratio of silver nitrate to α-ZrP is 1:15, and the reaction time of adding silver nitrate is 10h;

[0051] 3) Add silane coupling agent KH550 dropwise to continue the reaction; the mass ratio of the amount of KH550 added to α-ZrP is 1:1; the rate of addition is 0.1ml / min; the time for continuing the reaction is 5h;

[0052] 4) Add nitric acid with a mass fraction of 70% to treat nano-carbon black; the reaction temperature is 75°C, and the reaction time is 12 h.

[0053] 5) Add E51 modified acidified nano-carbon black; the molar ratio of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com