Method for preparing 16,17α-epoxy progesterone by biological method

An epoxy progesterone, biological method technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of severe reaction conditions, low effective reaction, large energy consumption, etc., and achieve mild reaction conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

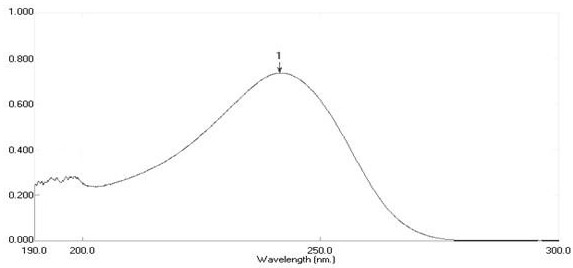

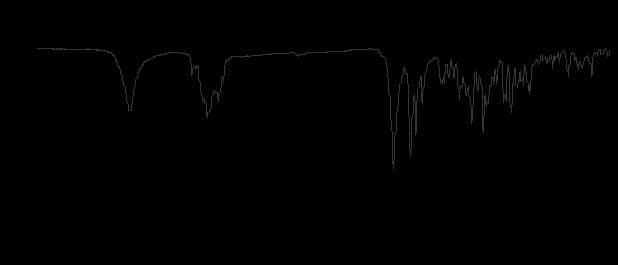

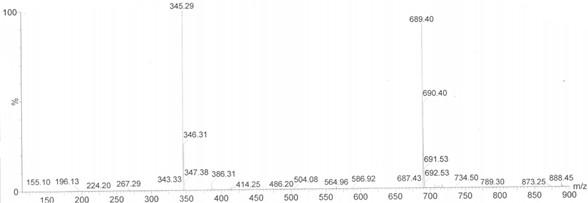

Image

Examples

Embodiment 1

[0035] The Arthrobacter simplex AS1.94 of the present invention comes from the Institute of Microbiology, Chinese Academy of Sciences, and the bacteria used for transformation or fermentation are obtained through slant culture and seed culture.

[0036] Incline culture

[0037] Incline medium: glucose 10g / L, yeast extract 10g / L, agar powder 20g / L.

[0038] Culture condition: 33±1℃

[0039] Culture time: 48h

[0040] seed culture

[0041] Seed medium: glucose 10g / L, yeast extract 5g / L, corn steep liquor 12g / L, potassium dihydrogen phosphate 2.5g / L.

[0042] Wash the slant culture with sterile normal saline to make a bacterial suspension, the bacterial concentration is greater than 1.0×108CFU / ml, 2.5m 3 For seed tanks, the inoculation amount is 1%, the rotation speed is 120r / min, and the ventilation is 1:0.5. The pressure of the seed tank is 0.05MPa, and the cultivation time is 22h. According to 1L of water, the fermentation substrate 3-hydroxy-5-ene-16,17α-epoxy is 2.5g, ...

Embodiment 2

[0046] Incline, seed culture method as described in Example 1.

[0047]According to 1L of water, the fermentation substrate 3-hydroxy-5-ene-16,17α-epoxy is 2.5g, the components and weight of the fermentation medium are glucose 12g, yeast extract 4g, corn steep liquor 35g, potassium dihydrogen phosphate 1.0g , foam enemy (defoamer GPE, Jiangsu Sterick Chemical Co., Ltd.) 0.2g ratio in 25m 3 The ventilated mechanical stirring fermenter is equipped with 18m 3 Fermentation liquid, adjust the initial pH to 6.7, sterilize with conventional hot and humid steam, cool to 33±1°C, inoculate the seed culture liquid at 25m under conventional aseptic conditions according to 12% inoculation amount 3 in the fermentation broth of the fermenter. The speed of the fermenter is 80r / min, the ventilation rate is 1:0.5, the pressure is 0.05MPa, the incubation time is 72h, sampling, TLC analysis, the conversion of the substrate is complete, the sample is extracted with ethyl acetate, and the upper l...

Embodiment 3

[0051] Incline, seed culture method as described in Example 1.

[0052] According to 1L of water, the fermentation substrate 3-hydroxy-5-ene-16,17α-epoxy is 2.5g, the components and weight of the fermentation medium are glucose 15g, yeast extract 5g, corn steep liquor 40g, potassium dihydrogen phosphate 1.2g , foam enemy (defoamer GPE, Jiangsu Sterick Chemical Co., Ltd.) 0.3g ratio in 25m 3 The ventilated mechanical stirring fermenter is equipped with 18m 3 For the fermentation broth, adjust the initial pH to 8.0, sterilize with conventional steam, cool to 33±1°C, and inoculate the seed culture solution at 25m under conventional aseptic conditions according to the inoculum size of 15%. 3 in the fermentation broth of the fermenter. The rotation speed of the fermenter is 80r / min, the ventilation rate is 1:0.5, the pressure of the seed tank is 0.05MPa, the incubation time is 72h, sampling, TLC analysis, the conversion of the substrate is complete, the sample is extracted with e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com