Nitrogen and phosphorus co-doped composite material, preparation method and application and capacitor electrode

A technology of capacitor electrodes and composite materials, which is used in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve the problems of low energy density, limited application and industrialized production, high current charge-discharge difference, etc., and achieve excellent electrical performance. , the effect of huge application potential and industrial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] S1: Mix egg yolk, deionized water and potassium ferricyanide, and ultrasonicate for 30 minutes; wherein, the mass ratio of egg yolk, deionized water and potassium ferricyanide is 1:10:5;

[0062] S2: after the end of ultrasound, dissolve for 30 minutes while stirring;

[0063] S3: After stirring and dissolving, fully dry at 120°C for 19 hours to obtain a crude product;

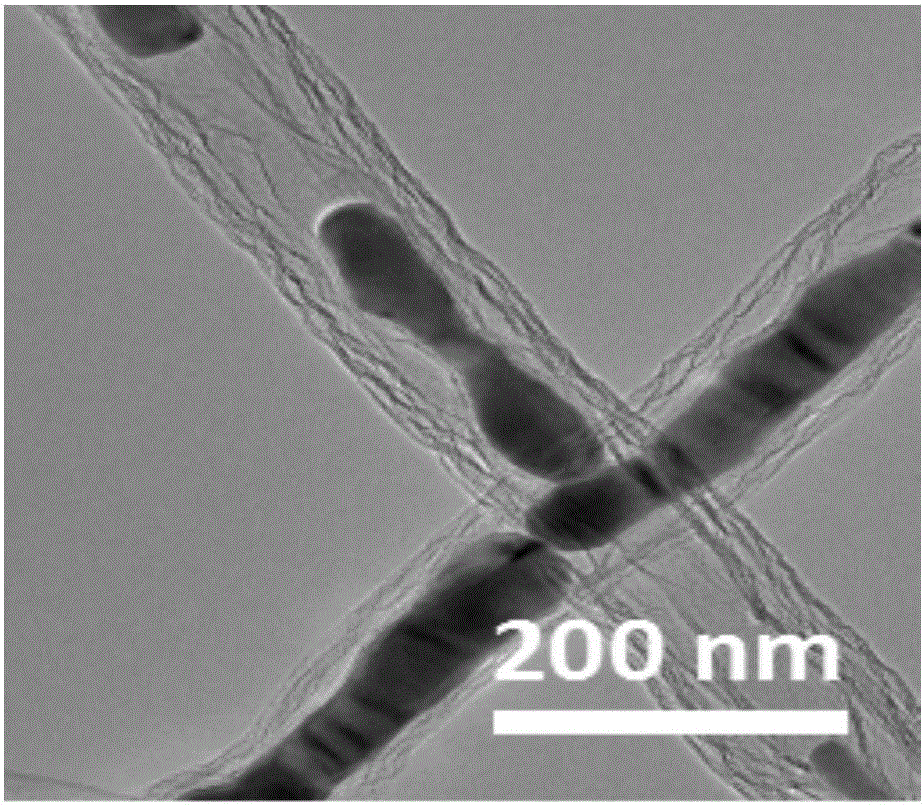

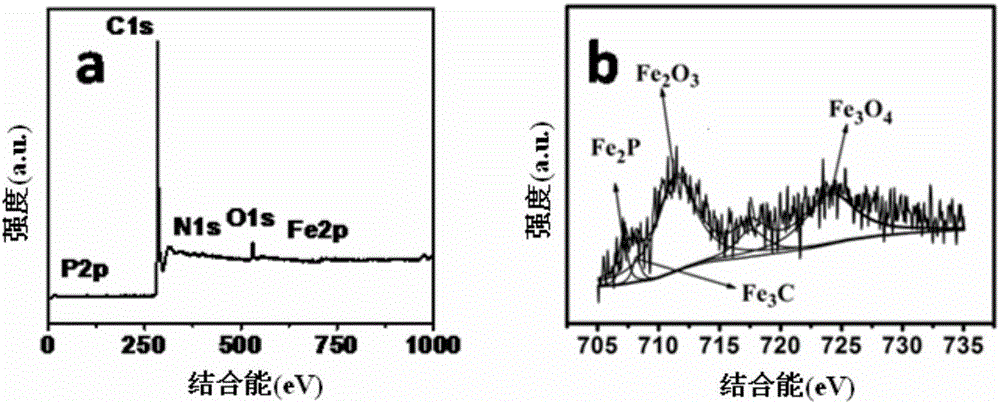

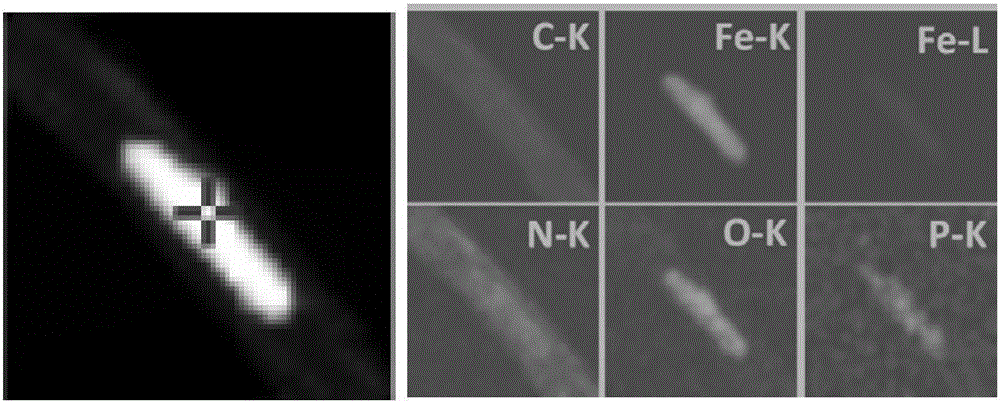

[0064] S4: The crude product was calcined at 1000° C. for 2 hours under the protection of nitrogen gas to obtain a nitrogen-phosphorus co-doped carbon nanotube-wrapped iron compound composite material, which was named M1.

Embodiment 2-3

[0065] Embodiment 2-3: the investigation of high temperature treatment temperature in step S4

[0066] Except that the high-temperature calcination treatment temperature in step S4 was replaced by 900°C and 1100°C respectively, other operations remained unchanged, so that Example 1 was repeated, and thus Examples 2-3 were carried out in sequence, and the obtained composite materials were named in sequence for M2 and M3.

Embodiment 4

[0067] Embodiment 4: the investigation when not adding iron compound in step S1

[0068] Except that the potassium ferricyanide in step S1 was omitted, other operations were kept unchanged, so that Example 1 was repeated to obtain Example 4, and the obtained material was named M4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacitance | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com