A high-performance environment-friendly silver tin oxide electrical contact material and its preparation method

An electric contact material, silver tin oxide technology, applied in the direction of oxide conductors, contacts, circuits, etc., to achieve the effect of improving anti-welding ability, improving anti-burning performance, and ensuring accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention also provides a method for preparing the above-mentioned high-performance environment-friendly silver tin oxide electrical contact material, comprising the following steps:

[0036] (1) Sphericalized micron or submicron tin oxide powders with different particle size distributions are prepared by subjecting nanoscale tin oxide powder raw materials to high temperature treatment at 1000-1400°C;

[0037] (2) After the spheroidized tin oxide powder is subjected to chemical co-precipitation treatment to deposit bismuth hydroxide colloid on the surface, the bismuth hydroxide is dehydrated to form bismuth trioxide, and finally sintered at 1000-1100°C to obtain a bismuth oxide layer. Tin oxide-bismuth oxide composite powders with different particle sizes were obtained;

[0038] The nanoscale tin oxide raw material of the present invention is sintered at different temperatures and high temperatures to obtain spherical tin oxide powders with different particl...

Embodiment 1

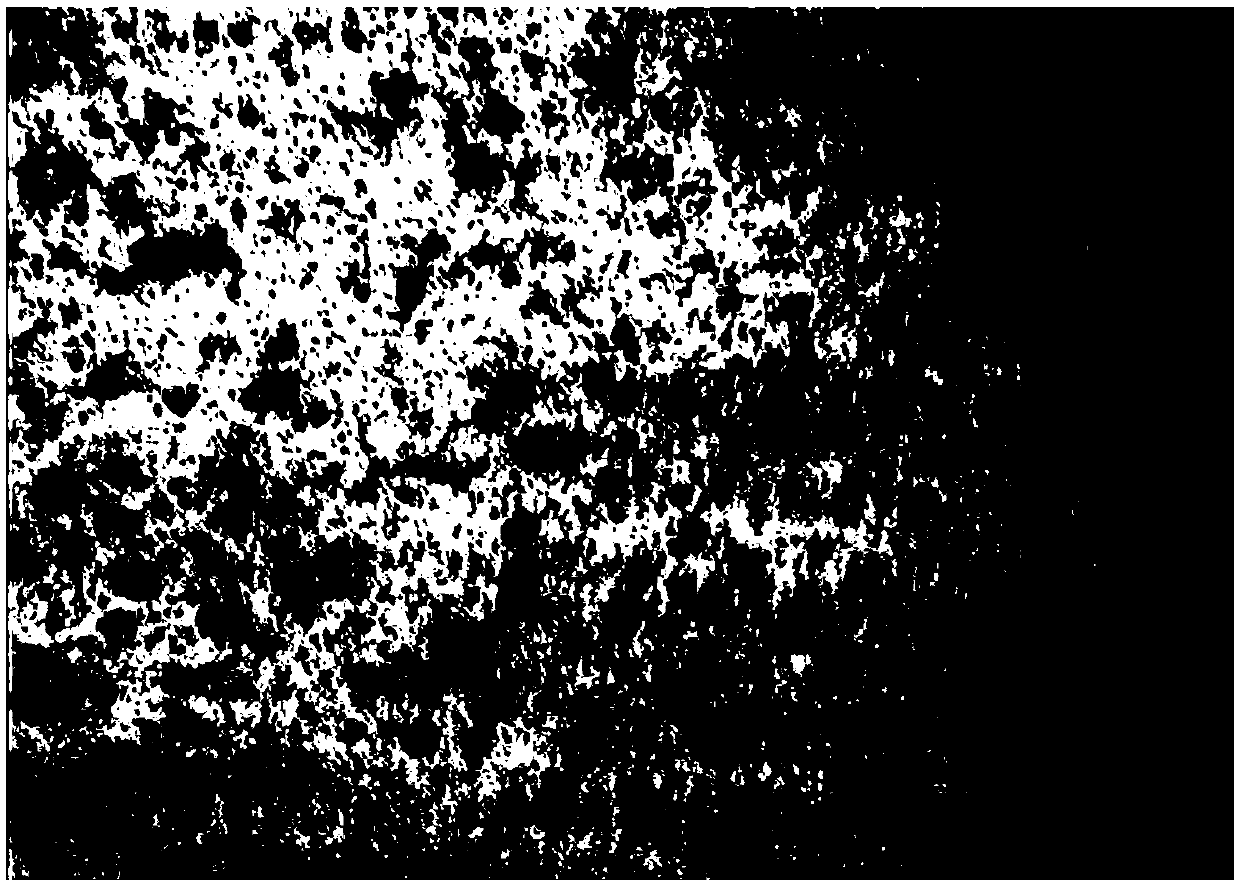

[0051] A high-performance environment-friendly silver tin oxide electrical contact material, which is composed of silver, tin oxide, bismuth oxide, and copper oxide, such as figure 1 Shown is the metallographic diagram of the silver tin oxide material prepared in Example 1; wherein the mass content of each component is 87.5% silver, 10.8% tin oxide, 1.4% bismuth oxide, and 0.3% copper oxide. The preparation steps are as follows :

[0052] (1) The pure tin oxide powder raw material at the nanometer level is calcined at a high temperature above 1000°C in an oxygen-rich atmosphere to prepare two kinds of spherical tin oxide powders with D50=0.2 μm and 2 μm, the ratio is 4:6, and the fine powder is as follows: figure 2 shown. In the embodiment of the present invention, the tin oxide powders used in different particle size ranges are selected according to the application conditions and requirements of the electrical contact, and this embodiment is only an example. Then two kind...

Embodiment 2

[0060] A high-performance environment-friendly silver tin oxide electrical contact material, which is composed of silver, tin oxide, bismuth oxide, and tungsten oxide, wherein the mass content of each component is 90% silver, 9% tin oxide, and 0.7% bismuth oxide , 0.3% tungsten oxide, its preparation steps are as follows:

[0061] (1) Two kinds of spheroidized tin oxide powders with D50=0.35 and 2.5 were prepared by calcining the nano-scale tin oxide raw material at a high temperature above 1000°C and in an air atmosphere, and mixed in a mass ratio of 2:8. In the embodiment of the present invention, the tin oxide powders used in different particle size ranges are selected according to the application conditions and requirements of the electrical contact, and this embodiment is only an example. Use pure water to disperse and mix tin oxide powder, deposit bismuth hydroxide colloid on the surface by conventional coating methods, age, dehydrate, and sinter at 1020°C to obtain two ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com