A kind of preparation method of lithium iron phosphate battery negative electrode material

A lithium iron phosphate battery and negative electrode material technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as poor carbon coating, reduced charge constant current ratio and discharge ratio, and electrode powder dropout, etc., to achieve Increase the number of embedded sites, improve charge and discharge performance and rate performance, and prevent stacking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The invention provides a method for preparing a lithium iron phosphate battery negative electrode material, comprising the following steps:

[0018] Step 1: Weigh the oxygen source, zinc source and nitrogen source according to a certain molar ratio, dissolve them in deionized water, and carry out ultrasonic stirring for 20-30 minutes, filter with suction, and dry the obtained solid in an air drying oven to obtain metal-organic Frame material NH 2 / Zn-TSCD;

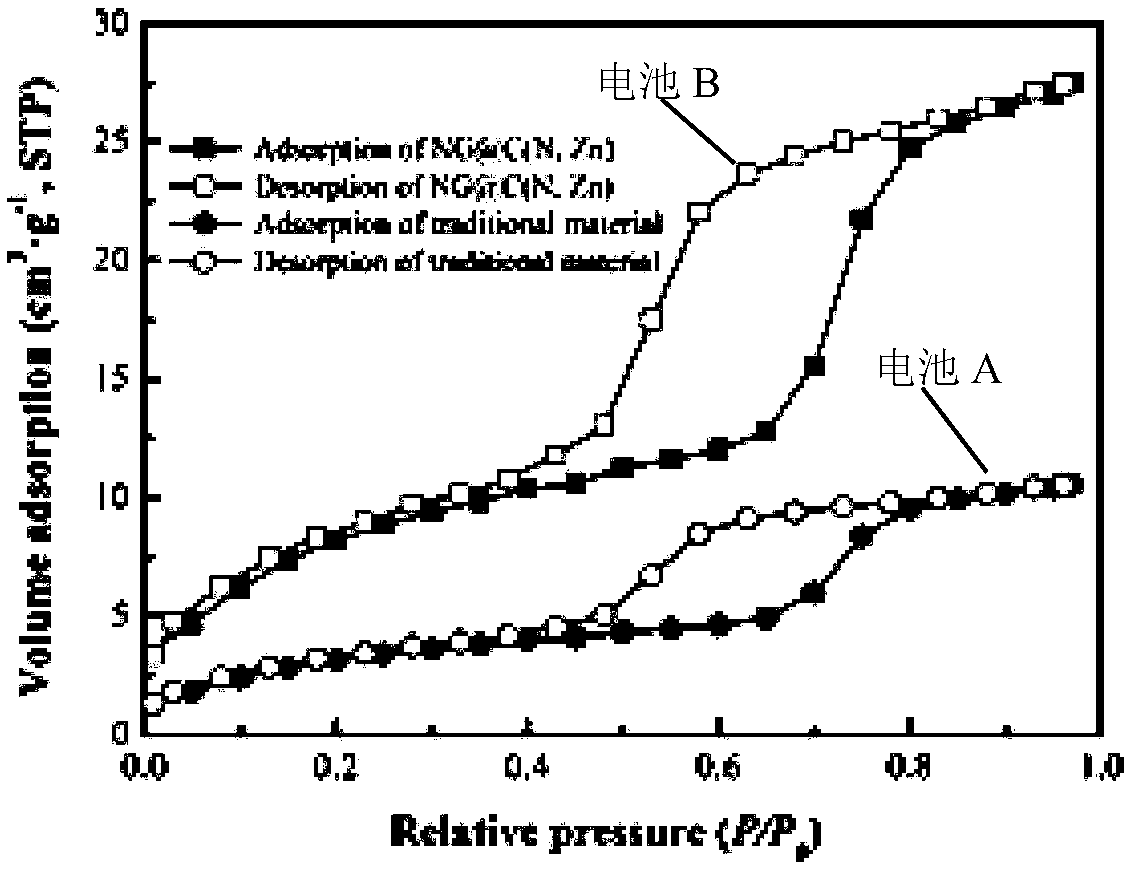

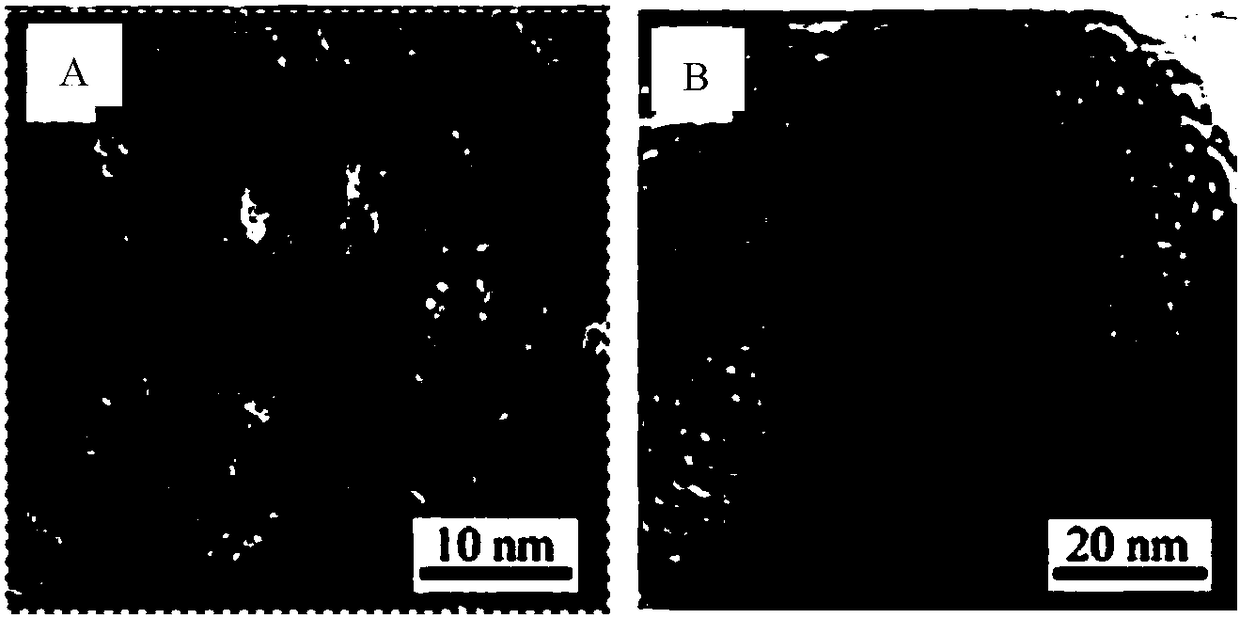

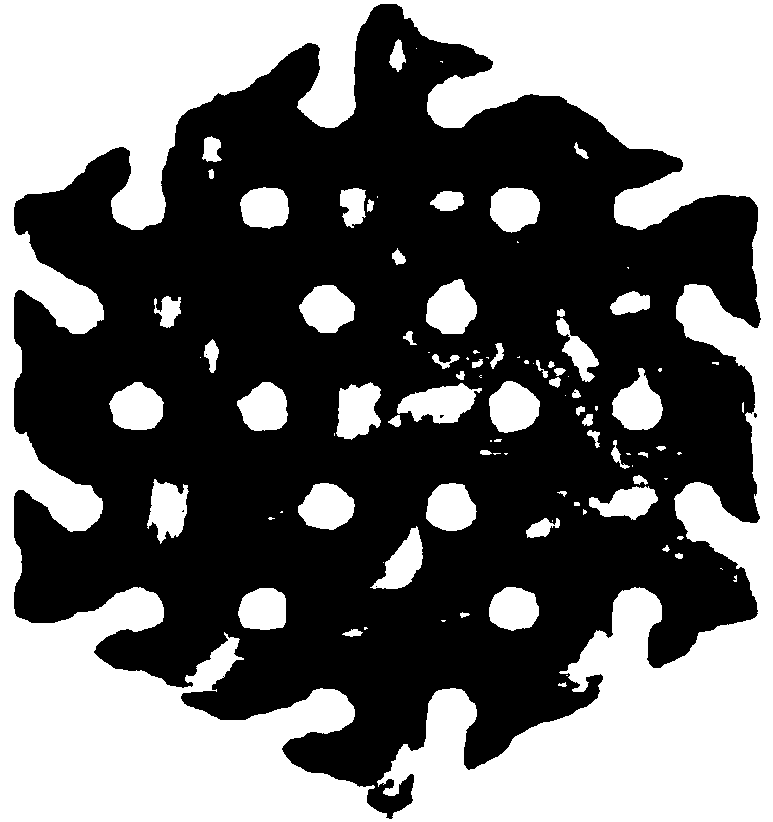

[0019] Step 2: The organic framework material NH obtained in Step 1 2 / Zn-TSCD placed full of N 2 Heating in a tube furnace, first raise the temperature to 340-360°C at a heating rate of 8-10°C / min, and keep for 1-2h; then raise the temperature to 960-1000°C at a heating rate of 3-5°C / min, and keep 3-5h; finally cool down to room temperature at a cooling rate of 5-10°C / min to obtain N, Zn-doped mesoporous carbon material C(N, Zn);

[0020] Step 3: Disperse the natural graphite and the N, Zn-doped mesoporous carb...

Embodiment 1

[0036] 1. Weigh 1.83g of ethylenediamine and dissolve it in 320ml of deionized water, add 44.1g of sodium citrate dihydrate and 29.7g of zinc nitrate hexahydrate, stir ultrasonically for 20min, filter with suction, and place the obtained solid in an air drying oven at 100°C After drying for 8 hours, the MOFs material NH 2 / Zn-TSCD;

[0037] 2. The MOFs material NH prepared in step 1 2 / Zn-TSCD placed full of N 2 In a tube furnace, the temperature was raised to 340°C at a heating rate of 8°C / min, kept for 2 hours, then raised to 960°C at a heating rate of 3°C / min, kept for 5 hours, and finally cooled to at a cooling rate of 5°C / min. At room temperature, obtain N, Zn-doped mesoporous carbon material C(N, Zn);

[0038] 3. Disperse 20 g of natural graphite and 0.5 g of the N, Zn-doped mesoporous carbon material C (N, Zn) prepared in step 2 in deionized water, and ultrasonically stir for 60 min; transfer the resulting solution to an autoclave in 110°C for hydrothermal treatment f...

Embodiment 2

[0040] 1. Weigh 3.09g of diethylenetriamine and dissolve it in 320ml of deionized water, add 44.1g of sodium citrate dihydrate and 18.3g of zinc acetate, stir ultrasonically for 20min, filter with suction, and dry the obtained solid in an air drying oven at 100°C 8h, get MOFs material NH 2 / Zn-TSCD;

[0041] 2. The MOFs material NH prepared in step 1 2 / Zn-TSCD placed full of N 2 In a tube furnace, the temperature was raised to 360°C at a heating rate of 8°C / min, kept for 1h, then raised to 1000°C at a heating rate of 3°C / min, kept for 3h, and finally cooled to At room temperature, obtain N, Zn-doped mesoporous carbon material C(N, Zn);

[0042] 3. Disperse 20 g of natural graphite and 0.5 g of the N, Zn-doped mesoporous carbon material C (N, Zn) prepared in step 2 in deionized water, and ultrasonically stir for 60 min; transfer the resulting solution to an autoclave in 120°C for hydrothermal treatment for 16 hours; the obtained product was subjected to suction filtration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com