Graphene, preparation method thereof and micro-jet device

A micro-jet, graphene technology, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as blockage, rupture, valve core wear, etc., to achieve the effect of simple process, low heat generation, and easy damage improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

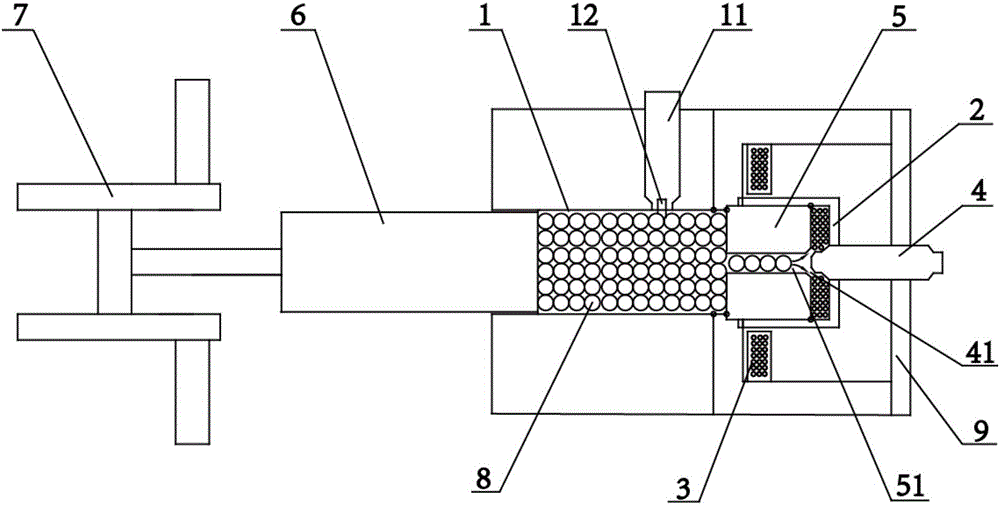

[0058] According to another aspect of the present invention, also provide a kind of preparation method of graphene, adopt above-mentioned micro-fluidic equipment to comprise the steps:

[0059] (1) graphite, dispersant, thickener and optional metal complexing agent are mixed, and the graphite dispersion is obtained after stirring;

[0060] (2) Move the graphite dispersion to the feeding chamber of the micro-fluidic equipment. Under the action of the piston, the graphite dispersion in the feeding chamber passes through the slit channel on the valve seat and the gap between the valve core and the valve seat. The annular gap enters the reaction chamber, and after several times of micro-jet circulation, the graphene solution is obtained;

[0061] (3) The graphene precipitation obtained after the graphene solution is centrifuged is dried to obtain graphene.

[0062] The invention provides a method for preparing graphene. The preparation method has simple process, convenient operat...

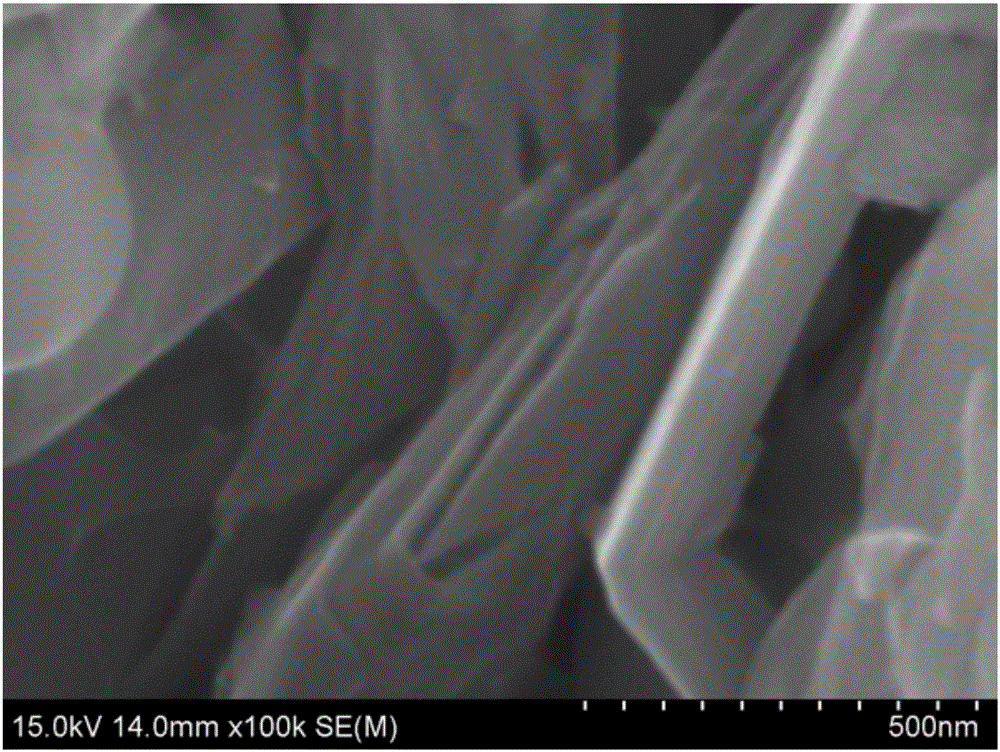

Embodiment 1

[0090] The invention provides a kind of preparation method of graphene, comprises the steps:

[0091] (1) Mix graphite, ethanol, water, polyethylene glycol and sodium polyacrylate at 60° C., and stir to obtain a graphite dispersion;

[0092] Wherein, according to weight fraction, graphite accounts for 1% by weight of raw materials, polyethylene glycol accounts for 1% by weight of raw materials, sodium polyacrylate accounts for 0.3% by weight of raw materials, and ethanol accounts for 2% by weight of raw materials. %, water to make up the balance to 100%.

[0093] (2) The graphite dispersion was moved to the micro-fluidic equipment, and after being circulated once at 160MPa micro-jet, a graphene solution was obtained.

[0094] (3) Precipitate the graphene obtained after the graphene solution is centrifuged, and dry to obtain graphene.

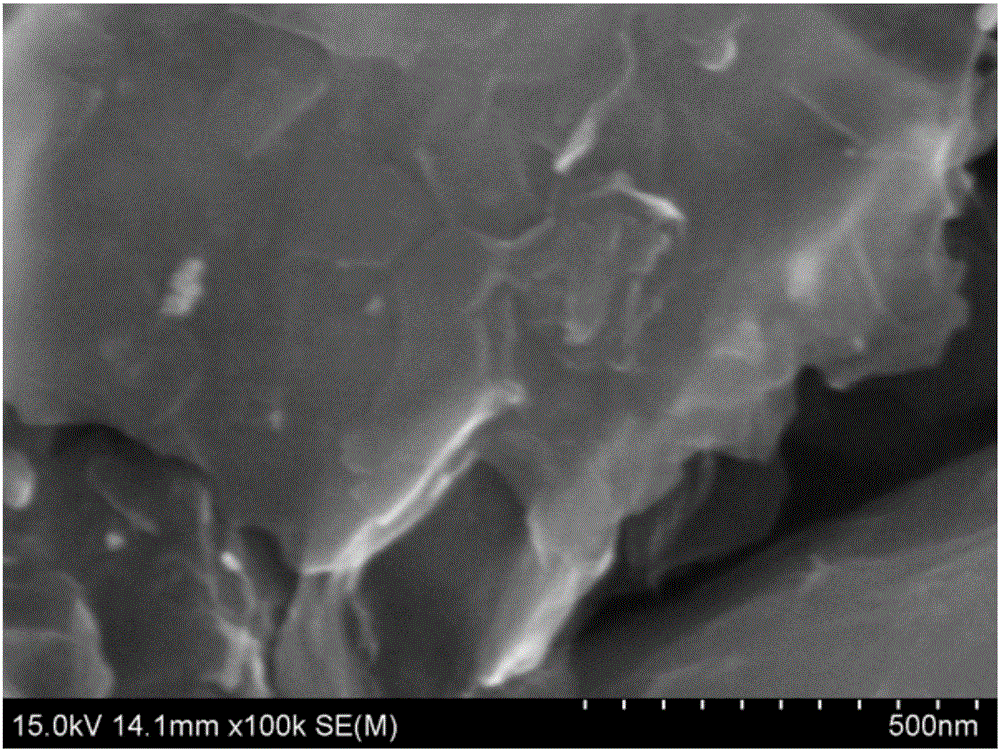

Embodiment 2

[0096] The invention provides a kind of preparation method of graphene, comprises the steps:

[0097] (1) Mix graphite, ethanol, water, polyethylene glycol and sodium polyacrylate at 60° C., and stir to obtain a graphite dispersion;

[0098] Wherein, according to weight fraction, graphite accounts for 1% by weight of raw materials, polyethylene glycol accounts for 1% by weight of raw materials, sodium polyacrylate accounts for 0.3% by weight of raw materials, and ethanol accounts for 2% by weight of raw materials. %, water to make up the balance to 100%.

[0099] (2) The graphite dispersion was moved to the micro-jet equipment, and after 3 times of 160MPa micro-jet circulation treatment, the graphene solution was obtained.

[0100] (3) Precipitate the graphene obtained after the graphene solution is centrifuged, and dry to obtain graphene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com