A kind of preparation method of anatase titanium dioxide/carbon composite material

A carbon composite material, titanium dioxide technology, applied in chemical instruments and methods, chemical/physical processes, special compound water treatment, etc. Achieve the effects of catalytic efficiency, low photogenerated electron-hole recombination rate, and short preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

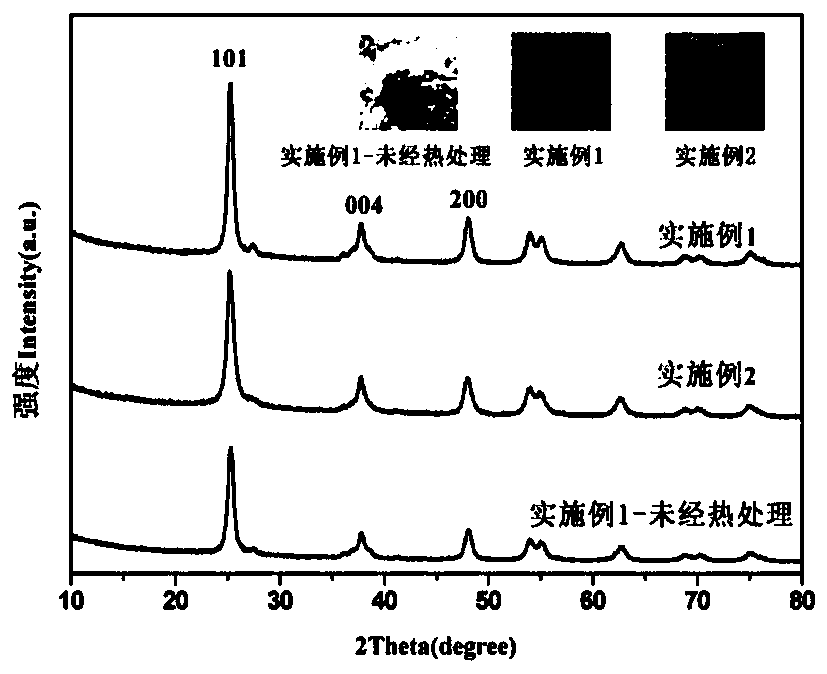

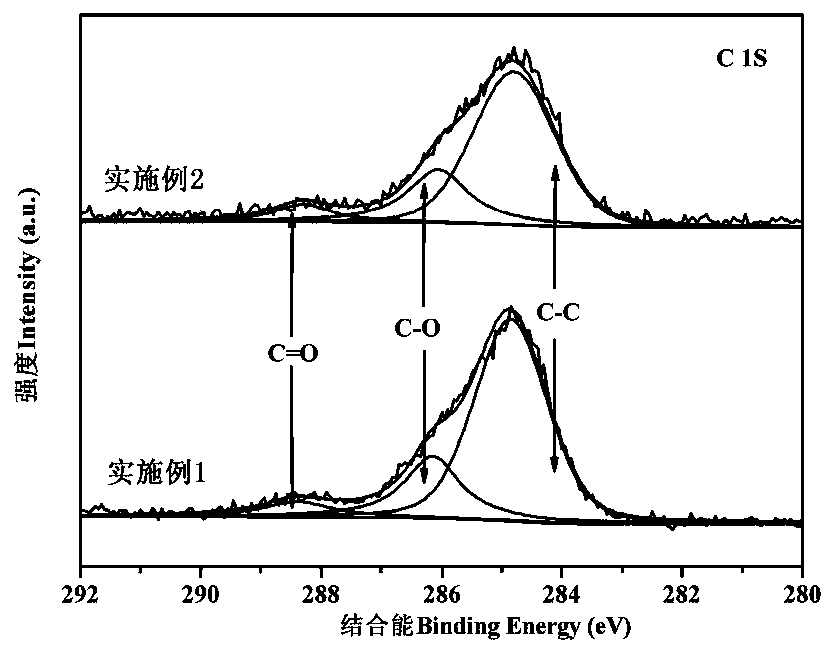

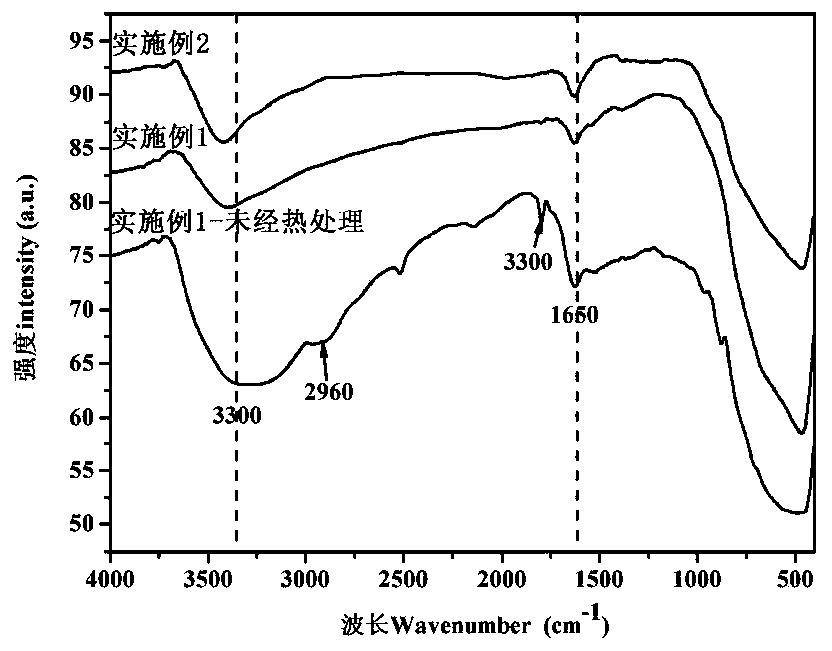

Embodiment 1

[0030] First benzyl alcohol and ethanol are mixed with 1:8 volume ratio to be mixed with 60ml di-alcohol solvent, stir 10 minutes, mix evenly; Add titanium tetrachloride in the di-alcohol solvent again under ice-water bath, the amount of titanium tetrachloride is 1.8 mol / L, continue to stir for 15 minutes, then transfer to a polytetrafluoroethylene autoclave for solvothermal reaction, the reaction temperature is 180°C, and the reaction time is 8 hours. Cool to room temperature after the reaction, centrifuge the product, wash the centrifuged product three times with absolute ethanol, and dry the product in a blast drying oven at 50°C for 5 hours. Anatase titanium dioxide with white organic surface modification was obtained by grinding, and finally placed in a muffle furnace, the temperature was raised to 300 °C at a rate of 10 °C / min, heat treated for 2 hours and then ground to obtain gray anatase titanium dioxide / carbon composite Material.

Embodiment 2

[0032]First benzyl alcohol and ethanol are mixed with 1:8 volume ratio to be mixed with 60ml di-alcohol solvent, stir 10 minutes, mix evenly; Add titanium tetrachloride in the di-alcohol solvent again under ice-water bath, the amount of titanium tetrachloride is 1.8 mol / L, continue to stir for 15 minutes, then transfer to a polytetrafluoroethylene autoclave for solvothermal reaction, the reaction temperature is 180°C, and the reaction time is 8 hours. Cool to room temperature after the reaction, centrifuge the product, wash the centrifuged product three times with absolute ethanol, and dry the product in a blast drying oven at 50°C for 5 hours. Anatase titanium dioxide modified by white organic matter surface was obtained by grinding, and finally placed in a tube furnace with argon as a protective atmosphere, the temperature was raised to 300 °C at a rate of 10 °C / min, heat treated for 2 hours and then ground to obtain a black sharp Titanium Titanium Dioxide / Carbon Composite. ...

Embodiment 3

[0034] First benzyl alcohol and ethanol are mixed with 1:5 volume ratio to be mixed with 60ml di-alcohol solvent, stir 10 minutes, mix evenly; Add titanium tetrachloride again in the di-alcohol solvent under ice-water bath, the amount of titanium tetrachloride is 1.8 mol / L, continue to stir for 15 minutes, then transfer to a polytetrafluoroethylene autoclave for solvothermal reaction, the reaction temperature is 180°C, and the reaction time is 8 hours. Cool to room temperature after the reaction, centrifuge the product, wash the centrifuged product three times with absolute ethanol, and dry the product in a blast drying oven at 50°C for 5 hours. Anatase titanium dioxide with white organic surface modification is obtained by grinding, and finally placed in a tube furnace with argon as a protective atmosphere, the temperature rises to 300 °C at a rate of 10 °C / min, heat treatment for 2 hours and then ground to obtain gray black Anatase Titanium Dioxide / Carbon Composite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com