A kind of preparation method of metallocene polymer nanoparticle

A metallocene compound and nanoparticle technology, applied in nanotechnology and other directions, can solve the problems of complex preparation methods, harsh synthesis conditions, low yields, etc., and achieve the effects of uniform particle size distribution, simple and mild synthesis conditions, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The preparation method of this embodiment is:

[0019] (1), 1.86 grams of ferrocene and 0.60 grams of paraformaldehyde were dissolved in 200 milliliters of ethylene dichloride, stirred at room temperature for 10 minutes to obtain a solution;

[0020] (2) Add 1.5 milliliters of boron trifluoride diethyl ether as a catalyst to the solution prepared in step 1, and carry out the reaction in a normal pressure vessel, the reaction temperature is 20-25°C, and the reaction time is 24 hours; as the reaction proceeds , the color of the reactant gradually becomes darker;

[0021] (3), after the reaction system of step (2) is cooled to room temperature, the reactant obtained is directly filtered to obtain a solid product;

[0022] (4) Repeatedly washing the obtained solid product with deionized water and drying to obtain ferrocene polymer nanoparticle powder.

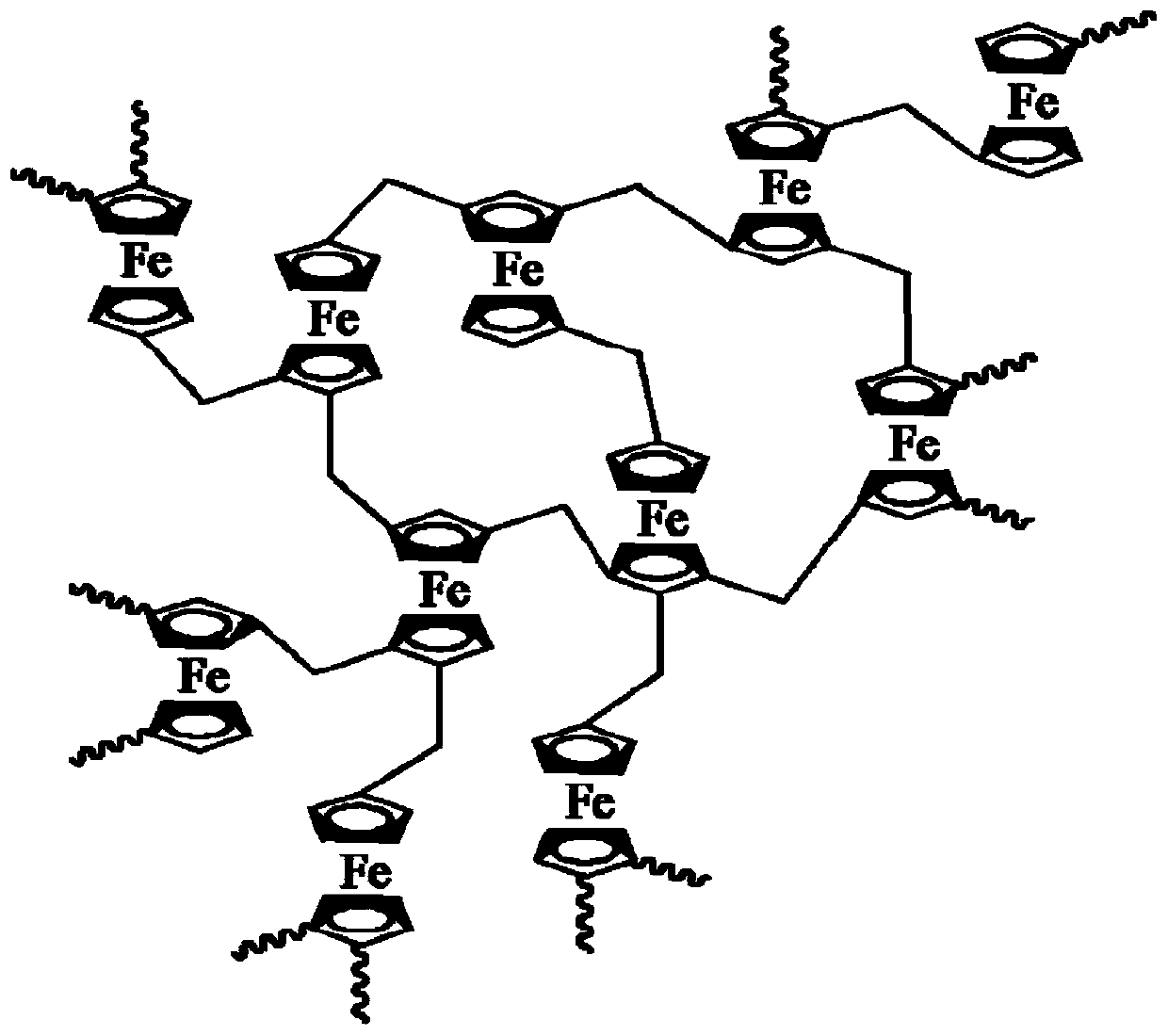

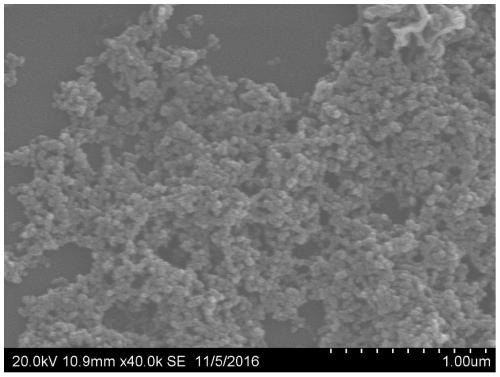

[0023] The molecular structure of the obtained ferrocene polymer nanoparticle powder is as follows: figure 1 , the scan...

Embodiment 2

[0026] The preparation method of this embodiment is:

[0027] (1), 1.86 grams of ferrocene and 1.52 grams of dimethoxymethane were dissolved in 200 milliliters of dichloroethane, and stirred at room temperature for 10 minutes to obtain a solution;

[0028] (2), add 1.5 milliliters of boron trifluoride diethyl ethers as catalyst in the solution that step 1 makes, carry out reaction in normal pressure container, and reaction temperature is 80 ℃, and reaction time is 24 hours; Along with the carrying out of reaction, reaction The color of the object gradually becomes darker;

[0029] (3), after the reaction system of step (2) is cooled to room temperature, the reactant obtained is soaked and washed with excess methanol to wash and filter the solid product obtained;

[0030] (4) Repeatedly washing the obtained solid product with deionized water, and freeze-drying to obtain ferrocene polymer nanoparticle powder.

[0031] The advantage of this embodiment: homogeneous reaction, the...

Embodiment 3

[0033] The preparation method of this embodiment is:

[0034] (1), 1.86 grams of ferrocene and 1.52 grams of dimethoxymethane were dissolved in 40 milliliters of dichloroethane, and stirred at room temperature for 1 minute to obtain a solution;

[0035] (2) Add 1.5 milliliters of boron trifluoride diethyl ether as a catalyst to the solution prepared in step 1, and react in an autoclave with a reaction temperature of 100° C. and a reaction time of 4 hours;

[0036] (3), after the reaction system of step (2) is cooled to room temperature, the reactant obtained is soaked and washed with excess methanol to wash and filter the solid product obtained;

[0037] (4) Repeatedly washing the obtained solid product with ethanol, and drying to obtain ferrocene polymer nanoparticle powder.

[0038] The advantage of this embodiment is that it is a solvothermal reaction, which greatly shortens the reaction time and reduces the amount of solvent used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com