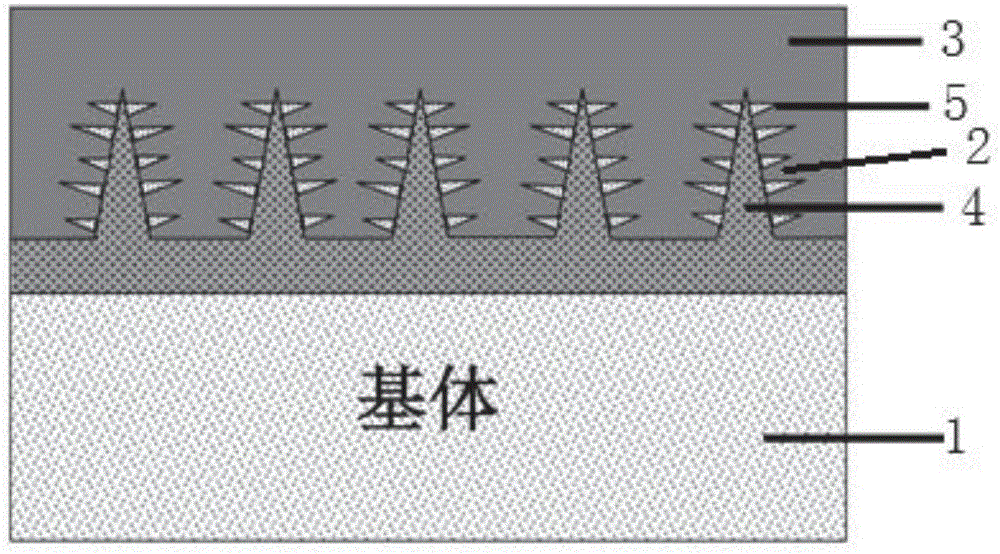

A method for restraining tin whisker growing based on micro-nano cone structure

A structure suppression, micro-nano technology, applied in the plating, coating, circuit and other directions of the superimposed layer, can solve the problems such as the thermodynamic driving force cannot be eliminated, the general applicable mechanism is not formed, and the bridge is not formed. The effect of disengagement and reduction of driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

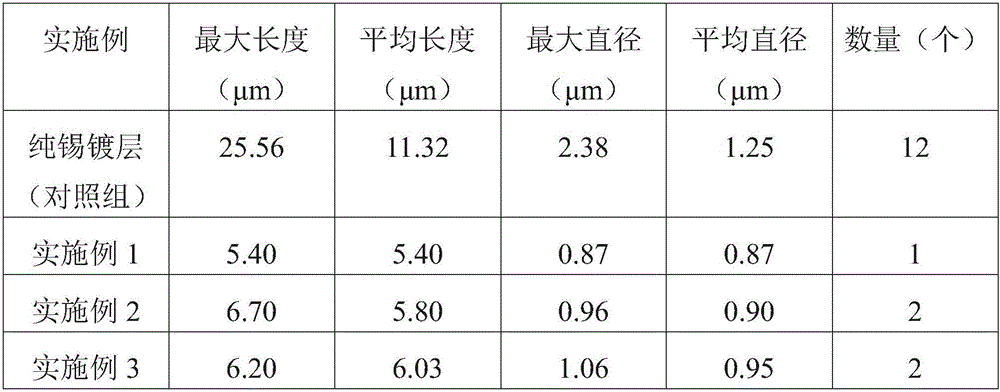

Embodiment 1

[0036] Select the lead frame C194 copper alloy as the conductive substrate, degrease the conductive substrate for 20s, the degreasing temperature is 40°C, the degreasing current is 3ASD (A / dm2), after cleaning with deionized water, wash with 20% dilute sulfuric acid for 20s, and then Rinse with deionized water; place the cleaned target substrate in the prepared plating solution at a temperature of 55°C, chemically deposit micron copper needles on the conductive substrate for 20 minutes, and obtain a copper needle structure with a length of about 5 μm. After cleaning with deionized water, put it in the nickel-plated needle plating solution, the solution temperature is 50°C, the current density is 1.2ASD, the plating time is 10min, and the nickel nano-micro cone with a length of about 500nm is obtained by electrodeposition on the micron copper needle. structure. Utilize 20% dilute sulfuric acid to pickle the obtained micro-nano needle cone structure to remove the oxide layer tha...

Embodiment 2

[0038] Select stainless steel as the conductive substrate, degreasing the conductive substrate for 30s, degreasing temperature 40°C, degreasing current 4ASD (A / dm2), after cleaning with deionized water, wash with 20% dilute sulfuric acid for 20s, and then rinse with deionized water Clean; placed in the nickel-plated needle plating solution, the solution temperature is 50°C, the current density is 1.0ASD, the electrodeposition time is 20min, and the nickel nanocone structure with a length of about 700nm is obtained by electrodeposition. Utilize 20% dilute sulfuric acid to pickle the obtained micro-nano needle cone structure to remove the oxide layer that may be exposed to the air, and then place it in a tin plating solution. The temperature of the plating solution is 25 ° C, and the current density is 1.2ASD. The electroplating time is 5 minutes, the thickness of the tin layer is about 2 μm, and the tin layer is cleaned and dried after electroplating.

Embodiment 3

[0040]Select semiconductor silicon as the substrate, first sputter a layer of 50 / 500nm Cr / Cu seed layer on the silicon substrate, wash it with 20% dilute sulfuric acid for 20s, and then rinse it with deionized water; place it in the nickel-plated needle plating solution, The temperature of the solution is 50° C., the current density is 1.0ASD, and the electrodeposition time is 20 minutes. A nickel nanocone structure with a length of about 700 nm is obtained by electrodeposition. Utilize 20% dilute sulfuric acid to pickle the obtained micro-nano needle cone structure to remove the oxide layer that may be exposed to the air, and then place it in a tin plating solution. The temperature of the plating solution is 25 ° C, and the current density is 1.2ASD. The electroplating time is 5 minutes, the thickness of the tin layer is about 2 μm, and the tin layer is cleaned and dried after electroplating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com