Preparation method of Li-doped ZnO crystal thin film

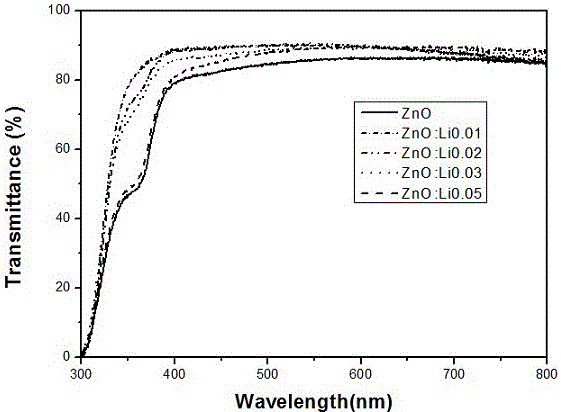

A thin film and crystal technology, applied in the field of preparation of p-type ZnO crystal thin film, can solve problems such as difficult practice of large-scale production, limitation of nano-device application, time-consuming reaction, etc., to achieve good light-transmitting and conductive properties, surface The effect of good appearance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

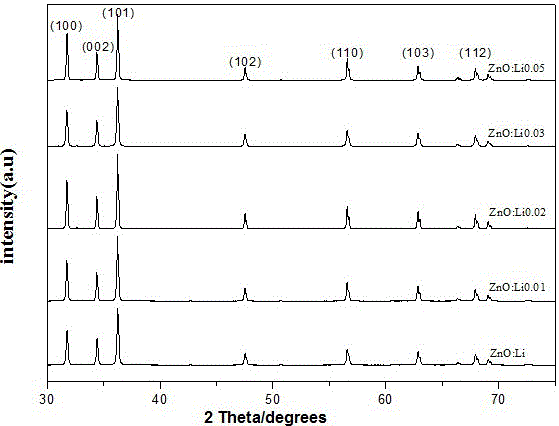

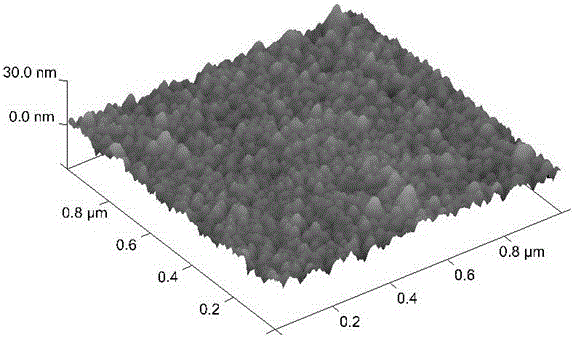

[0023] Weigh 2.46g of Zn(CH 3 COO) 2 2H 2 O was dissolved in 100ml of ethylene glycol methyl ether solvent, 10g of citric acid was added, and after stirring in a water bath at 70°C for 2 hours, a uniform colloidal solution was obtained, and the solution was left to stand for 24 hours to obtain a sol; a glass sheet was used as a substrate, The substrate was ultrasonically cleaned in acetone, absolute ethanol and deionized water for 10 minutes, then rinsed with absolute ethanol, and then dried on a heating platform; Coating. Slowly dip the glass slide into the sol at a descending speed of 3000mm / s, and use the sol to have a certain viscosity to make the wet sol adhere to the glass slide. Then the glass slide is slowly pulled out of the wet gel by a constant speed motor at a pulling speed of 1333mm / s. The pulling height is 90mm, and the residence time is 480s. The wet gel is evenly distributed by gravity. on both sides of the glass slide. Repeat the above lifting process 2 t...

Embodiment 2

[0026] Weigh 2.46g of Zn(CH 3 COO) 2 2H 2 Dissolve O in 100ml of ethylene glycol methyl ether solvent, add 10g of citric acid, stir in a water bath at 70°C for 1h, and then press Li + accounted for Zn 2+ Add LiCl at a molar ratio of 1% and continue to stir for 2 hours to obtain a uniform colloidal solution. Let the solution stand for 24 hours to obtain a sol; select a glass sheet as the substrate, and place the substrate in acetone, absolute ethanol and deionized water in sequence. Ultrasonic cleaning for 10 minutes, followed by rinsing with absolute ethanol, and drying on a heating platform; the obtained sol was coated on the cleaned substrate material by dipping and pulling method. Slowly dip the glass slide into the sol at a descending speed of 3000mm / s, and use the sol to have a certain viscosity to make the wet sol adhere to the glass slide. Then the glass slide is slowly pulled out of the wet gel by a constant speed motor at a pulling speed of 1333mm / s. The pulling h...

Embodiment 3

[0028] Weigh 2.46g of Zn(CH 3 COO) 2 2H 2 Dissolve O in 100ml of ethylene glycol methyl ether solvent, add 10g of citric acid, stir in a water bath at 70°C for 1h, and then press Li + accounted for Zn 2+ Add LiCl at a molar ratio of 2%, and continue to stir for 2 hours to obtain a uniform colloidal solution. The solution is left to stand for 24 hours to obtain a sol; use a glass sheet as the substrate, and place the substrate in acetone, absolute ethanol and deionized water in sequence. Ultrasonic cleaning for 10 minutes, followed by rinsing with absolute ethanol, and drying on a heating platform; the obtained sol was coated on the cleaned substrate material by dipping and pulling method. Slowly dip the glass slide into the sol at a descending speed of 3000mm / s, and use the sol to have a certain viscosity to make the wet sol adhere to the glass slide. Then the glass slide is slowly pulled out of the wet gel by a constant speed motor at a pulling speed of 1333mm / s. The pull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com