Ceramic coating with closed-cell properties and lithium ion battery diaphragm containing ceramic coating

A lithium-ion battery and ceramic coating technology, which is applied to battery components, circuits, electrical components, etc., can solve problems such as unevenness, pore size distribution of base film plugging, and achieve small thermal shrinkage, low closed cell temperature, The effect of high membrane rupture temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

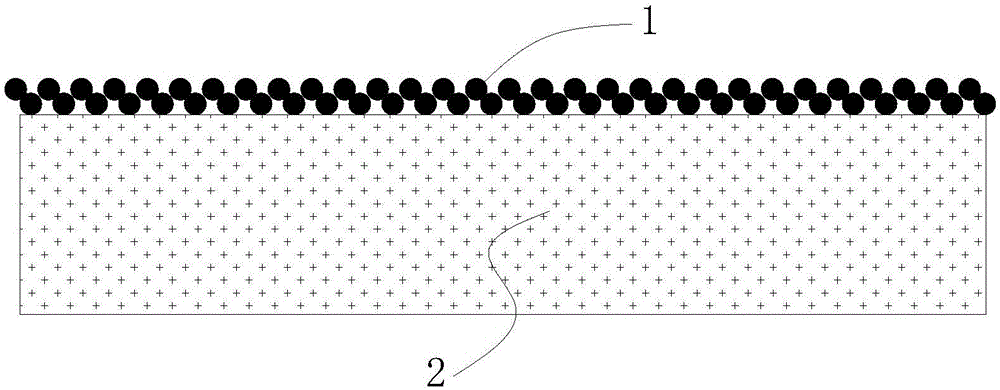

[0039] The lithium-ion battery separator in this example includes a polyolefin microporous membrane and a ceramic coating with closed-pore performance coated on one side of the polyolefin microporous membrane. The preparation process of the coating slurry is as follows: 30g of aluminum oxide and 15g of low-density polyethylene particles modified by vinyltrimethoxysilane are added to a container containing 50g of N,N-dimethylacetamide , stir evenly, then add 5g of polyvinylidene fluoride, stir at high speed, and ball mill to form a slurry. Use a coating machine to coat the prepared slurry on a dry-process PP film with a thickness of 20 μm, an air permeability of 242s / 100ml, and a shrinkage rate of 3% at 130°C. Dry for 20min.

[0040] Wherein, the coupling agent modification treatment of Al2O3 comprises the following steps:

[0041] A: Dilute vinyltrimethoxysilane with ethanol and water. Wherein the volume ratio of vinyltrimethoxysilane, ethanol and deionized water is 20:72:8...

example 1

[0045] The air permeability, shrinkage rate and membrane rupture temperature of the membrane in Example 1 are shown in Table 1.

[0046] Table 1 Performance test of PP separator coated with closed-cell performance ceramic coating

[0047] Type of diaphragm Air permeability after baking (s / 100ml) 130℃ / 2h Shrinkage (%) Membrane rupture temperature (°C) PP film 263 3 175 Example 1 Plugging 0.75 226

[0048] It can be seen from Table 1 that a layer of ceramic coating with closed-cell performance is coated on one side of the PP separator, which has good low-temperature closed-cell performance and high membrane rupture temperature, and effectively improves the safety performance of lithium-ion batteries.

Embodiment 2

[0050] The lithium-ion battery separator in this example includes a polyolefin microporous membrane and a ceramic coating with closed-pore performance coated on one side of the polyolefin microporous membrane. The preparation process of the coating slurry is as follows: 30g of silicon dioxide and 15g of ethylene-vinyl acetate modified by 3-aminopropyltriethoxysilane are added to a container filled with 50g of N,N-dimethylacetamide In the container, stir evenly, then add 5g of polyvinylidene fluoride, stir at high speed, and ball mill to form a slurry. Use a coating machine to coat the prepared slurry on a dry-process PP film with a thickness of 20 μm, an air permeability of 242s / 100ml, and a shrinkage rate of 3% at 130°C. Dry for 20min.

[0051] The coupling agent modification treatment of silica is as in Example 1.

[0052] Diaphragm performance test as example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com