Method for preparing magnetic carbon material from core-shell metal organic framework

A metal-organic framework, organic framework technology, applied in separation methods, alkali metal compounds, chemical instruments and methods, etc., can solve the problems of small specific surface area of magnetic carbon materials, difficult to apply in the field of catalysis, and narrow application range, and achieves an increase in the number of materials. Diversity, beneficial to industrial production, simple and fast preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

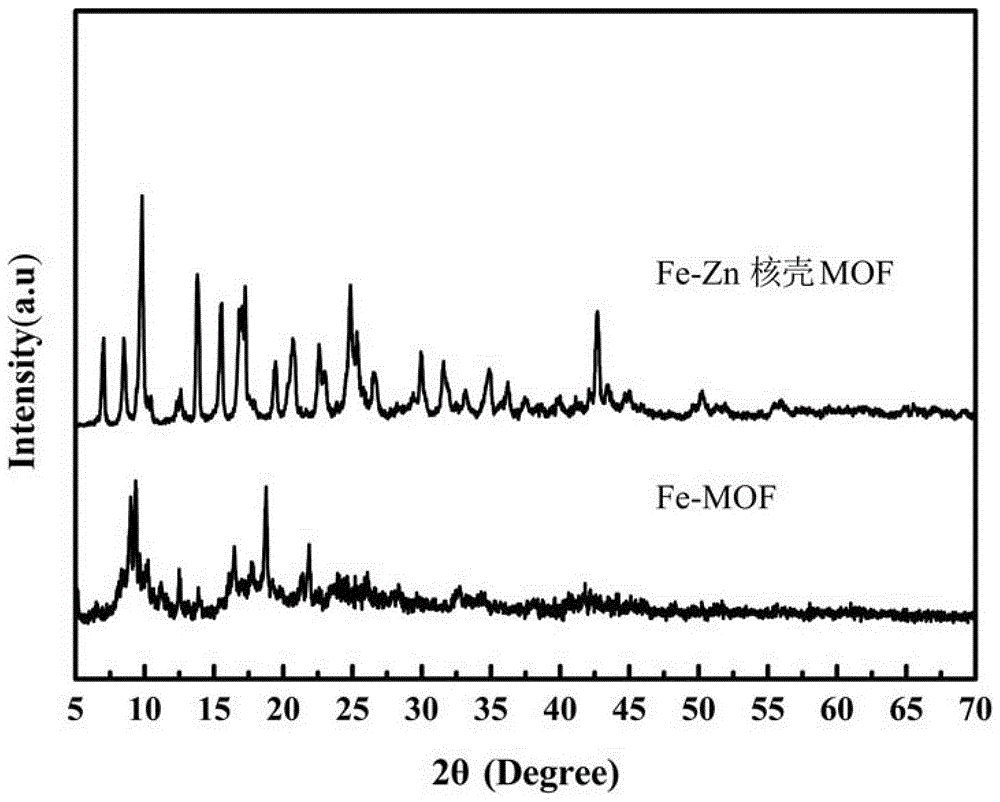

[0037] Using Fe-MOF as the core and MOF-5(Zn) as the shell to prepare Fe-Zn core-shell MOF, and using Fe-Zn core-shell MOF as the precursor, magnetic carbon materials with high specific surface area were prepared by high-temperature carbonization.

[0038] The metal element in Fe-MOF is iron (Fe), and the coordinated organic compound is terephthalic acid. The preparation method of this substance is to weigh 1.6230g ferric chloride hexahydrate and 0.8405g trimesic acid and dissolve them in 40mL distilled water , add 4 drops of fluoboric acid dropwise, stir evenly and transfer to a high-pressure reactor with tetrafluoroethylene liner, react at 150°C for 24 hours to obtain the product, and obtain Fe-MOF after vacuum drying at 150°C for 12 hours.

[0039] Preparation of Fe-Zn core-shell MOF First prepare the reaction solution of MOF-5(Zn), dissolving 2.9749g zinc nitrate hexahydrate and 0.8310g terephthalic acid in 80mL N,N-dimethylformamide solution, Add 4 drops of fluoboric acid...

Embodiment 2

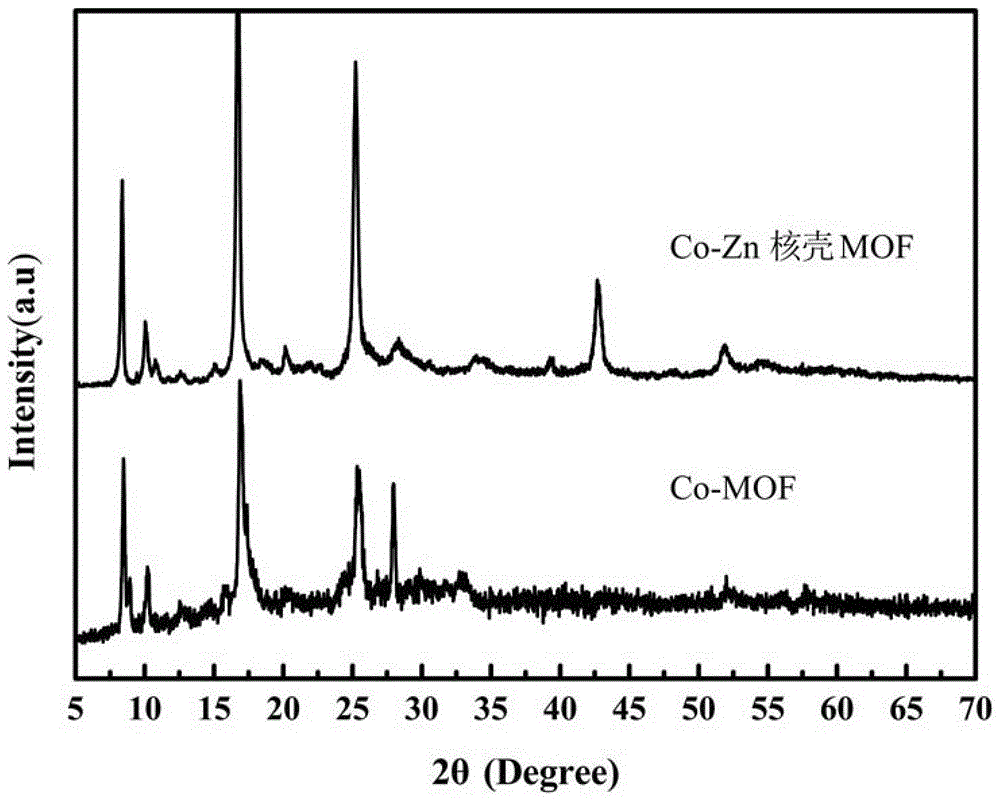

[0042] The main method is the same as in Example 1, the difference is that this example uses another metal organic framework material Co-MOF as the core, MOF-5 (Zn) as the shell to prepare Co-Zn core-shell MOF, and Co- Zn core-shell MOF is used as the precursor, and magnetic carbon materials with high specific surface area are prepared by high-temperature carbonization.

[0043] The metal element in Co-MOF is cobalt (Co), and the coordinated organic compound is terephthalic acid. The preparation method of this substance is to dissolve 2.9103g cobalt nitrate hexahydrate and 0.8310g terephthalic acid in 80mL N,N- Dimethylformamide solution, stirred evenly and transferred to a high-pressure reactor with a tetrafluoroethylene liner, reacted at 100°C for 24 hours to obtain the product, and obtained Co-MOF after vacuum drying at 100°C for 4 hours.

[0044] Preparation of Co-Zn core-shell MOF First prepare the reaction solution of MOF-5(Zn), dissolve 2.9749g zinc nitrate hexahydrate ...

Embodiment 3

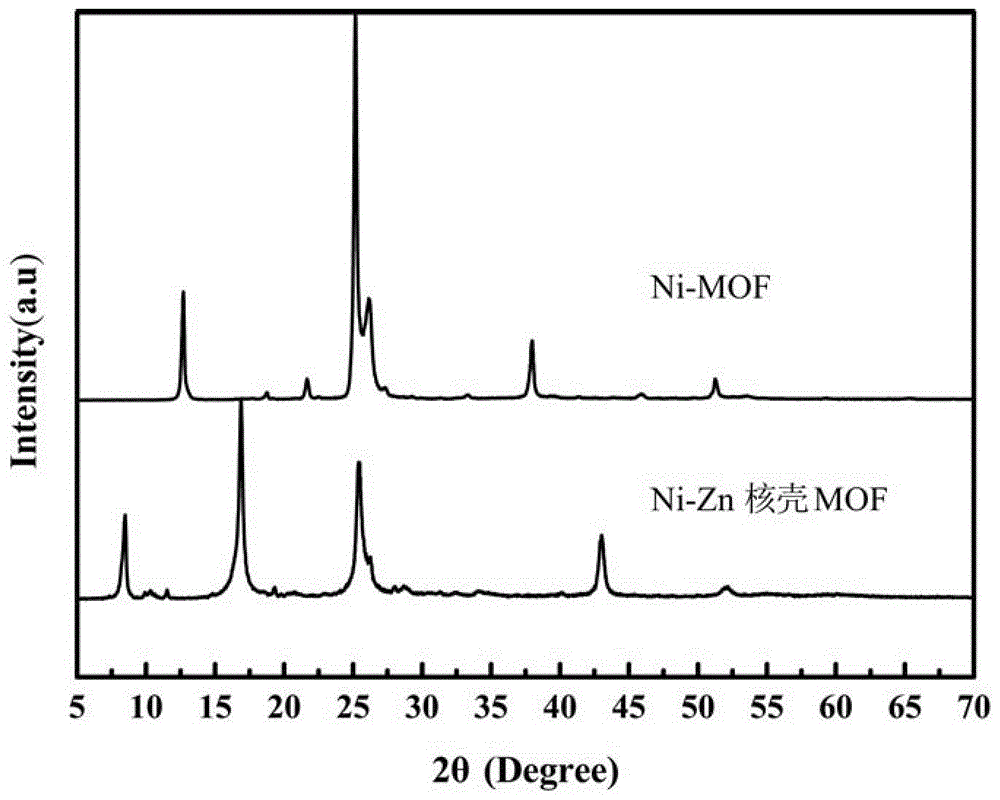

[0047] The main method is the same as in Example 1, the difference is that in this example, Ni-MOF, another metal-organic framework material, is used as the core and MOF-5(Zn) is used as the shell to prepare Ni-Zn core-shell MOF, and Ni- Zn core-shell MOF is used as the precursor, and magnetic carbon materials with high specific surface area are prepared by high-temperature carbonization.

[0048] The metal element in Ni-MOF is nickel (Ni), and the coordinated organic compound is trimesic acid. The preparation method of this substance is to dissolve 1.4560g nickel nitrate and 0.8306g trimesic acid in 80mL N,N-dimethyl In the base formamide solution, stir evenly and transfer to a high-pressure reactor with a tetrafluoroethylene liner, react at 100 ° C for 48 hours to obtain the product, and obtain Ni-MOF after vacuum drying at 100 ° C for 4 hours. Analyzed by powder X-ray diffraction (see image 3 ), it is found that there are obvious diffraction peaks, indicating that the Co-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com