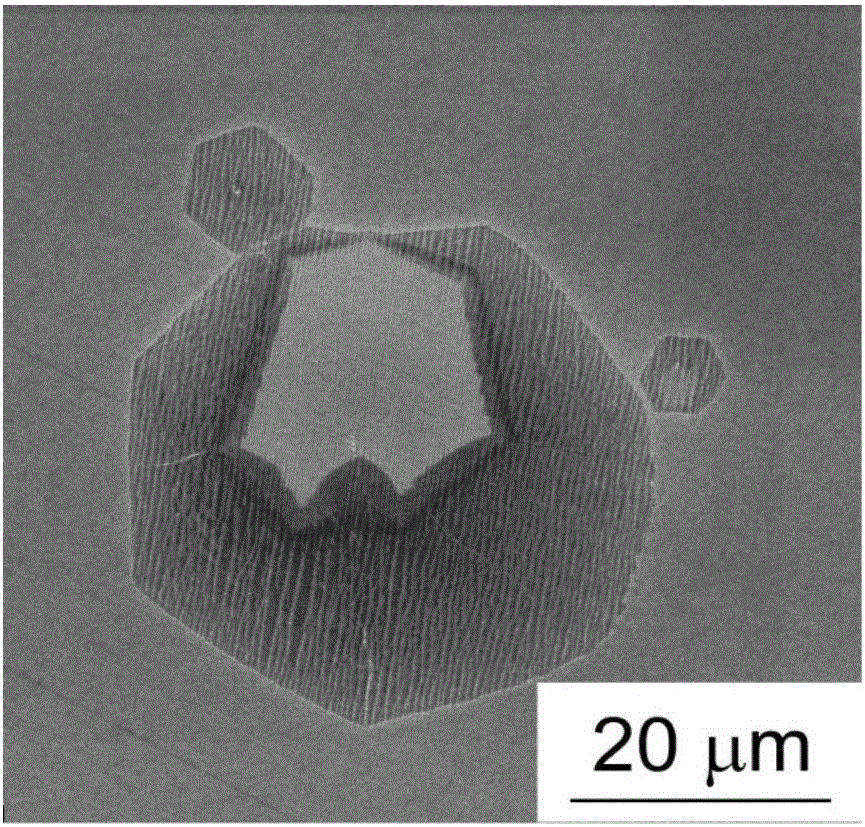

Concave structure monocrystalline graphene and preparation method thereof

A technology of single crystal graphene and concave shape, which is applied in the field of controllable preparation of single crystal graphene, can solve problems such as high cost, and achieve the effects of low cost, simple preparation method and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

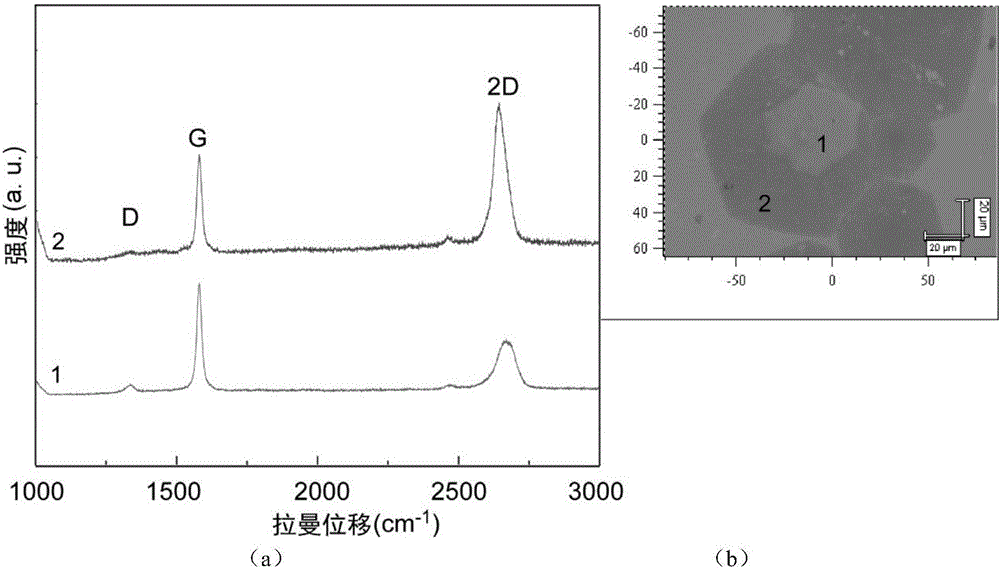

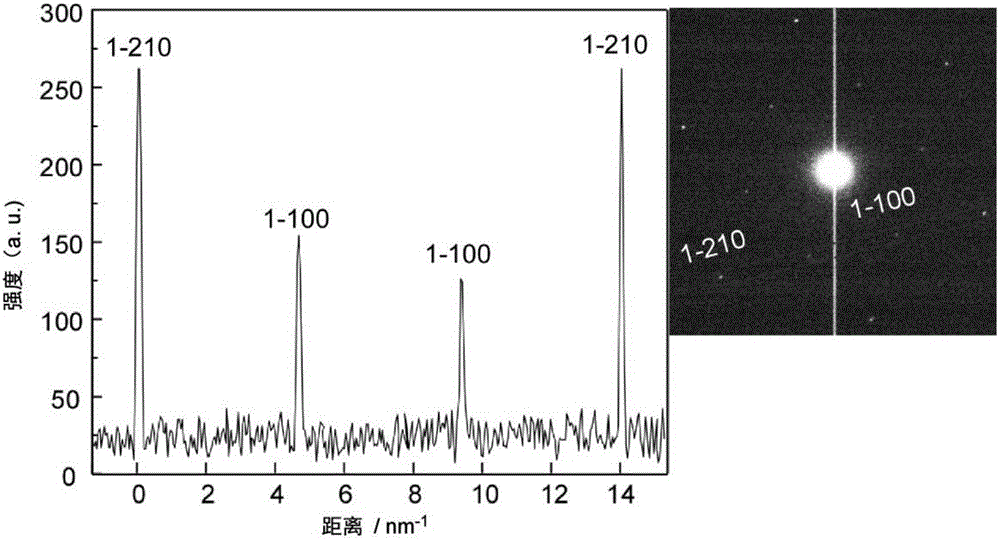

Embodiment 1

[0024] A method for preparing single crystal graphene with a concave structure includes the following steps:

[0025] 1) Cut the copper foil with an area of 2cm×2cm, and use acetic acid (purity of 99.5% by weight) and acetone (concentration of 99.5% by weight) to ultrasonically clean the copper foil for 20 minutes; put the cleaned copper foil into a quartz tube. The diameter of the tube is 6cm, the length is 100cm, and 500sccm of Ar is passed into it, and it is kept for 30min to ensure that the air in the quartz tube is exhausted, and then 50sccm of H is passed into it at the same time 2 ,Raise to 1050℃ at a rate of 15℃ / min, keep for 90min (annealing), turn off H 2 ;

[0026] 2) Maintain the Ar gas flow in step 1) to exhaust the H in the quartz tube 2 , Then enter the O of 3sccm 2 Carry out pre-oxidation treatment, keep for 5min, oxidation temperature is 1050℃, close O 2 ; Keep the flow of Ar in step 2) unchanged, H 2 The flow rate is increased to 300sccm, and 1sccm CH 4 , Carry o...

Embodiment 2

[0031] A method for preparing single crystal graphene with a concave structure includes the following steps:

[0032] 1) Cut the copper foil with an area of 2cm×2cm, and use acetic acid (purity of 99.5wt%) and acetone (concentration of 99.5wt%) to ultrasonically clean the copper foil for 30 minutes; put the cleaned copper foil into a quartz tube. The diameter of the tube is 6cm, the length is 100cm, and 750sccm of Ar is passed into it, and kept for 30min, to ensure that the air in the quartz tube is exhausted, and then 75sccm of H is passed into it at the same time 2 ,Raise to 1065℃ at a rate of 15℃ / min, keep it for 100min, turn off H 2 (annealing);

[0033] 2) Keep the Ar gas flow in step 1) exhausting H in the quartz tube 2 , Then enter the O of 4sccm 2 , Keep for 7min, oxidation temperature 1065℃, close O 2 ; Keep the flow of Ar in step 2) unchanged, H 2 The flow rate is increased to 400sccm, and 1.2sccm CH 4 , Carry out chemical vapor deposition at a temperature of 1065℃, and ...

Embodiment 3

[0037] A method for preparing single crystal graphene with a concave structure includes the following steps:

[0038] 1) Cut the copper foil with an area of 2cm×2cm, and use acetic acid (purity of 99.5% by weight) and acetone (concentration of 99.5% by weight) to ultrasonically clean the copper foil for 40 minutes; put the cleaned copper foil into a quartz tube. The diameter of the tube is 6cm, the length is 100cm, and 1000sccm of Ar is passed into it, and kept for 30min to ensure that the air in the quartz tube is exhausted, and then 100sccm of H is passed into it at the same time 2 , Rise to 1080°C at a rate of 15°C / min, keep it for 120min (annealing), turn off H 2 ;

[0039] 2) Keep the Ar gas flow in step 1) exhausting H in the quartz tube 2 , Then enter 5sccm O 2 Carry out pre-oxidation treatment, keep for 10 minutes, the oxidation temperature is 1080 ℃, close O 2 ; Keep the flow of Ar in step 2) unchanged, H 2 The flow rate is increased to 500sccm, and 1.5sccm CH 4 , Carry o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com