Polypropylene composition and preparation method thereof

A polypropylene composition and propylene polymer technology, applied in the field of new materials, can solve the problems that propylene polymers cannot meet, less surface crystal points, etc., and achieve excellent molding processability and mechanical properties, less crystal points and defects, and the method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

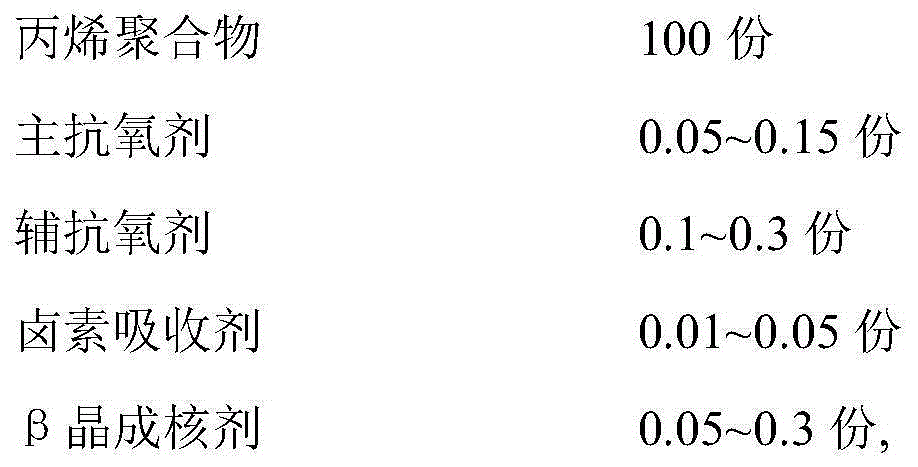

Method used

Image

Examples

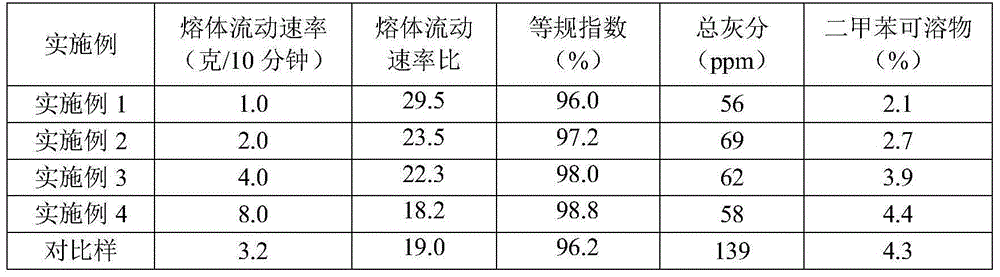

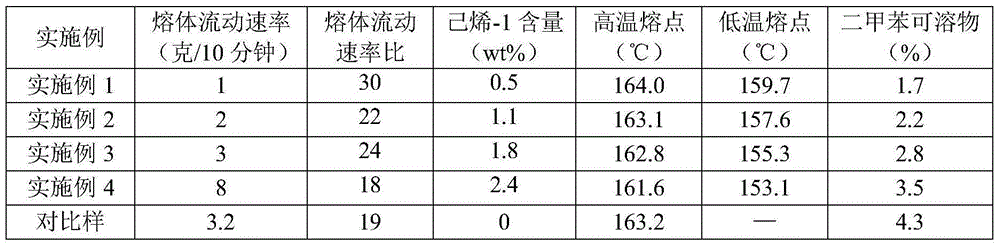

Embodiment 1

[0048] Preparation of homopolypropylene:

[0049] The polymerization reaction is carried out in a 10L autoclave (bulk polymerization): inject 2L of liquid propylene into the autoclave that has been purged with hot nitrogen for more than 3 times, add 6ml of cocatalyst triethylaluminum, start stirring, and then inject 2L of liquid propylene ; Add 11 mg of HA catalyst and 30 g of hydrogen, and finally inject 1 L of liquid propylene, flush all the catalyst into the reactor, and close the feed valve. Raise the temperature of the high-pressure polymerization reactor to 70°C within 15 to 20 minutes, then count the time, discharge the residual gas after 2 hours of reaction, and discharge the material to obtain white homopolypropylene powder. After the homopolypropylene powder is fully dried, the total weight of the polymer is weighed to 1040 grams, and the catalytic efficiency of the catalyst is calculated to be 95,000 times.

[0050] Preparation of polypropylene composition:

[005...

Embodiment 2

[0054] Preparation of homopolypropylene:

[0055] The polymerization reaction is carried out in a 10L autoclave (bulk polymerization): inject 2L of liquid propylene into the autoclave that has been purged with hot nitrogen for more than 3 times, add 6ml of cocatalyst triethylaluminum, start stirring, and then inject 2L of liquid propylene ; Add 10 mg of HA catalyst and 70 g of hydrogen, and finally inject 1 L of liquid propylene, flush all the catalyst into the reactor, and close the feed valve. Raise the temperature of the high-pressure polymerization reactor to 70°C within 15 to 20 minutes, then count the time, discharge the residual gas after 2 hours of reaction, and discharge the material to obtain white homopolypropylene powder. After the homopolypropylene powder is fully dried, the total weight of the polymer is weighed to 1180 grams, and the catalytic efficiency of the catalyst is calculated to be 118,000 times.

[0056] Preparation of polypropylene composition:

[00...

Embodiment 3

[0059] Preparation of homopolypropylene:

[0060] The polymerization reaction is carried out in a 10L autoclave (bulk polymerization): inject 2L of liquid propylene into the autoclave that has been purged with hot nitrogen for more than 3 times, add 6ml of cocatalyst triethylaluminum, start stirring, and then inject 2L of liquid propylene ; Add 8 mg of HA catalyst and 150 g of hydrogen, and finally inject 1 L of liquid propylene, flush all the catalyst into the reactor, and close the feed valve. Raise the temperature of the high-pressure polymerization reactor to 70°C within 15 to 20 minutes, then count the time, discharge the residual gas after 2 hours of reaction, and discharge the material to obtain white homopolypropylene powder. After the homopolypropylene powder is fully dried, the total weight of the polymer is weighed to 790 grams, and the catalytic efficiency of the catalyst is calculated to be 99,000 times.

[0061] Preparation of polypropylene composition:

[0062...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com