Liquid nitrogen pulverization-gas chromatography method for detecting harmful substances of acrylonitrile, styrene and ethylbenzene in packaging materials

A technology of liquid nitrogen crushing and gas chromatography, which is applied in the fields of styrene, acrylonitrile and ethylbenzene in food packaging materials, can solve the problems of small proportion of harmful substances, low detection limit and limited solubility, and achieve Fast and accurate qualitative analysis, strong operability and low detection limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

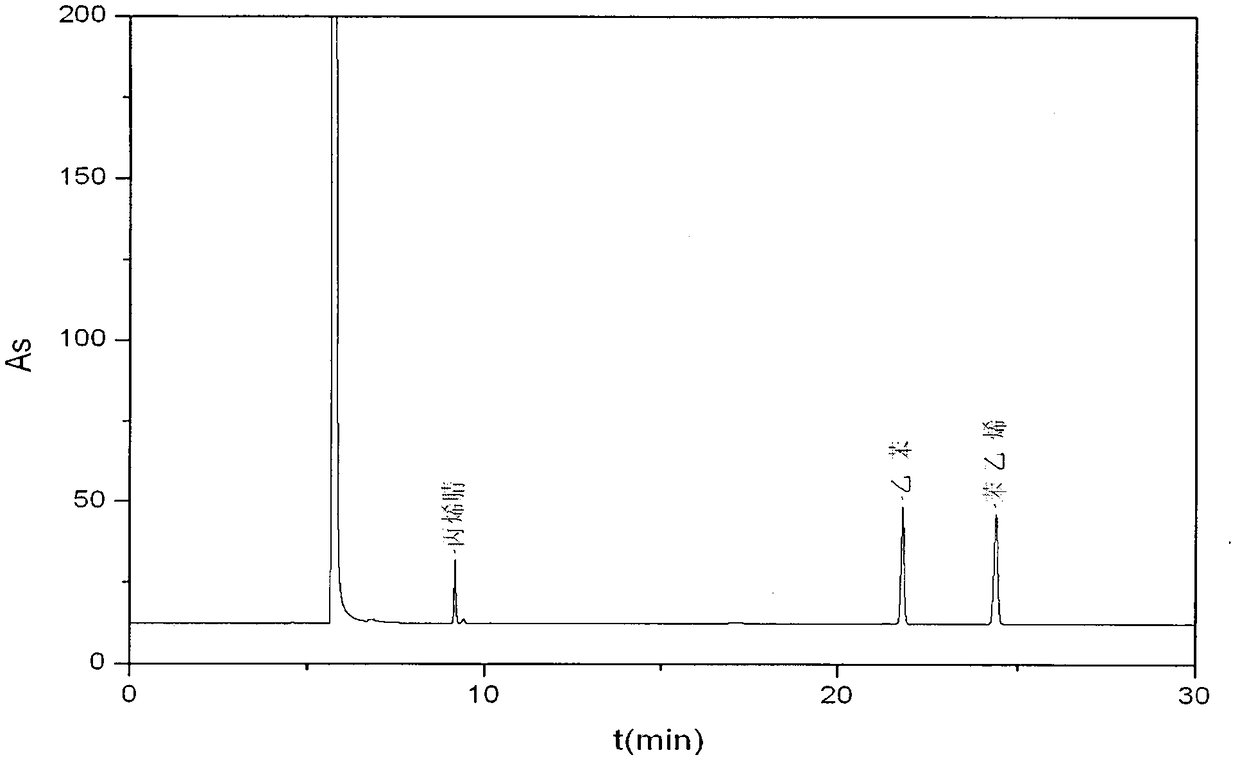

[0027] Cut the AS material into pieces of about 0.5cm×0.5cm, cool in liquid nitrogen for 10 minutes, and pulverize in a liquid nitrogen pulverizer. Weigh 0.5g of the pulverized sample into a 22mL headspace bottle, seal it quickly, press The above-mentioned chromatographic conditions were used for detection, and the retention time of each substance was used for qualitative determination and the standard curve for quantitative determination. The samples were tested 6 times in parallel. The analysis results are shown in Table 1. Through analysis, the relative standard deviation (RSD) of parallel samples is 2.07%-2.83%, and the repeatability is good.

[0028] Table 1. Contents of acrylonitrile, ethylbenzene and styrene in AS samples

[0029] Numbering

Embodiment 2

[0031] Cut the ABS material into fragments of about 0.5cm×0.5cm, cool in liquid nitrogen for 10 minutes, and crush in a liquid nitrogen pulverizer. Weigh 0.5g of the pulverized sample into a 22mL headspace bottle, seal it quickly, press The above-mentioned chromatographic conditions were used for detection, and the retention time of each substance was used for qualitative determination and the standard curve for quantitative determination. The samples were tested 6 times in parallel. The analysis results are shown in Table 2. Through analysis, the relative standard deviation (RSD) of parallel samples is 1.37%-3.33%, and the repeatability is good.

[0032] Table 2. Contents of acrylonitrile, ethylbenzene and styrene in ABS samples

[0033] Numbering

Embodiment 3

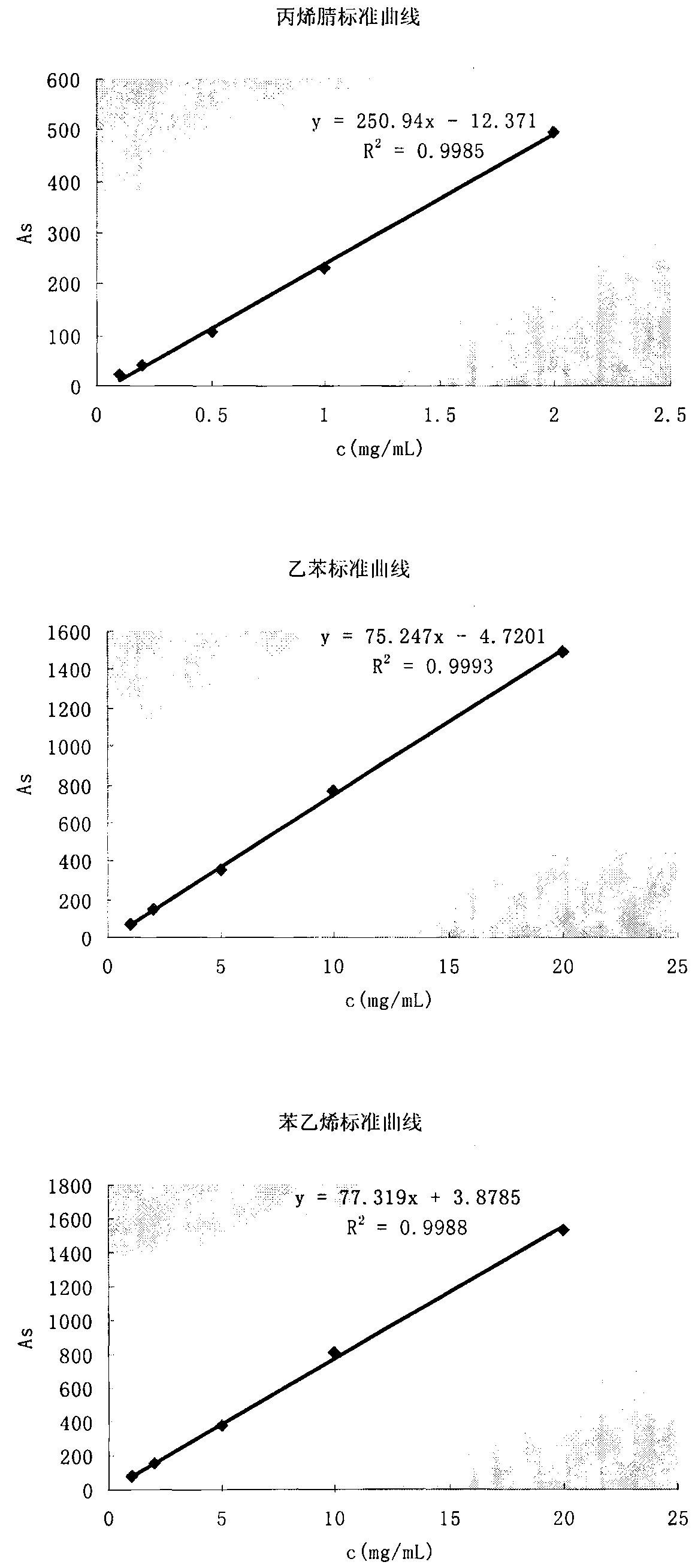

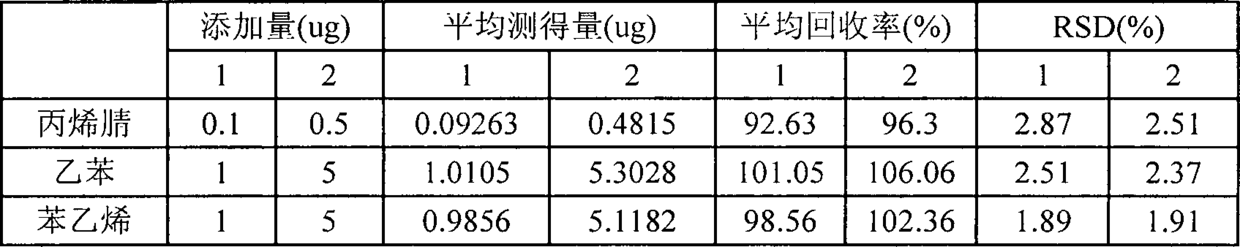

[0035] Cut the AS material whose content has been measured above into pieces of about 0.5cm×0.5cm, place it in liquid nitrogen to cool for 10 minutes, place it in a liquid nitrogen pulverizer, and pulverize it. After weighing the sample, add two levels of standards Solution, 6 parallel samples were made for each content level, and the recovery rate and standard deviation were calculated. The results are shown in Table 3. The standard addition recovery rate was between 92.63% and 106.06%, and the relative standard deviation was between 1.89% and 2.87%. The method is reliable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com