Multistage structure cobalt hydroxide electrode material and preparation method therefor

A technology of cobalt hydroxide and electrode materials, which is applied in the field of material chemistry, can solve the problems of unfavorable electron rapid transport, poor specific surface area, and few active sites, so as to overcome the few active sites, high specific capacitance, and small specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A multi-level structure cobalt hydroxide electrode material and a preparation method thereof, comprising the steps of:

[0033] (1) Preparation of cobalt-aluminum double metal hydroxide

[0034] a. First, at room temperature, add 10mg of cobalt nitrate and 5mg of aluminum nitrate into a 100ml beaker, and add 30ml of deionized water into it and stir for 15min to obtain a mixed solution;

[0035] b. Then add 10mg of urea to the above solution and stir for 15min;

[0036] c. Then transfer the above solution into a high-pressure reactor for hydrothermal reaction at a temperature of 90°C for 12 hours;

[0037] d. After the reaction, cool down to room temperature naturally, centrifuge and wash the sample, and then put it into a freeze dryer for freeze-drying for 24 hours;

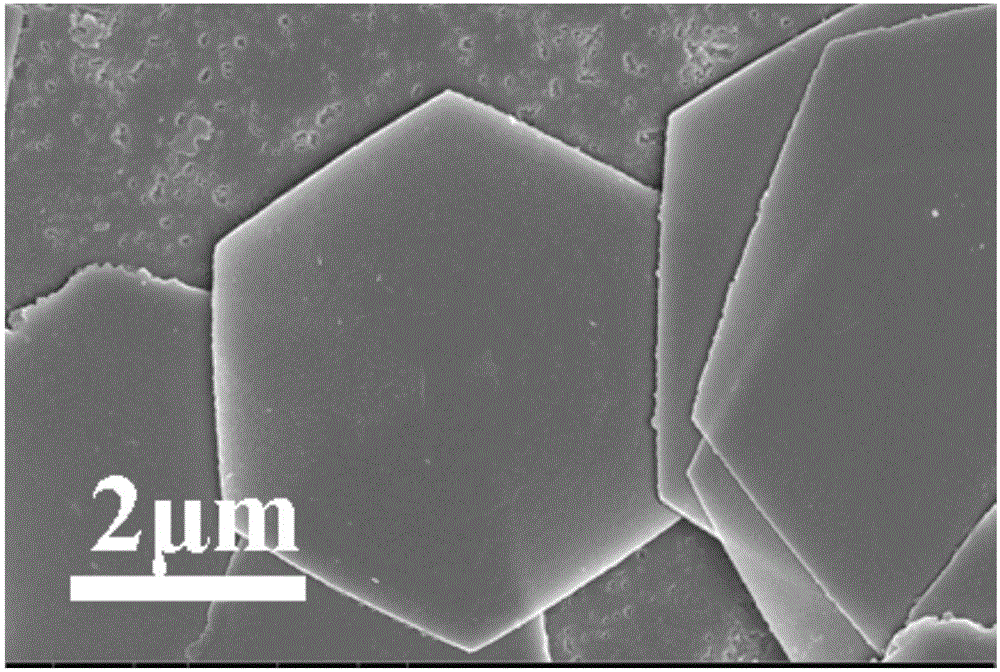

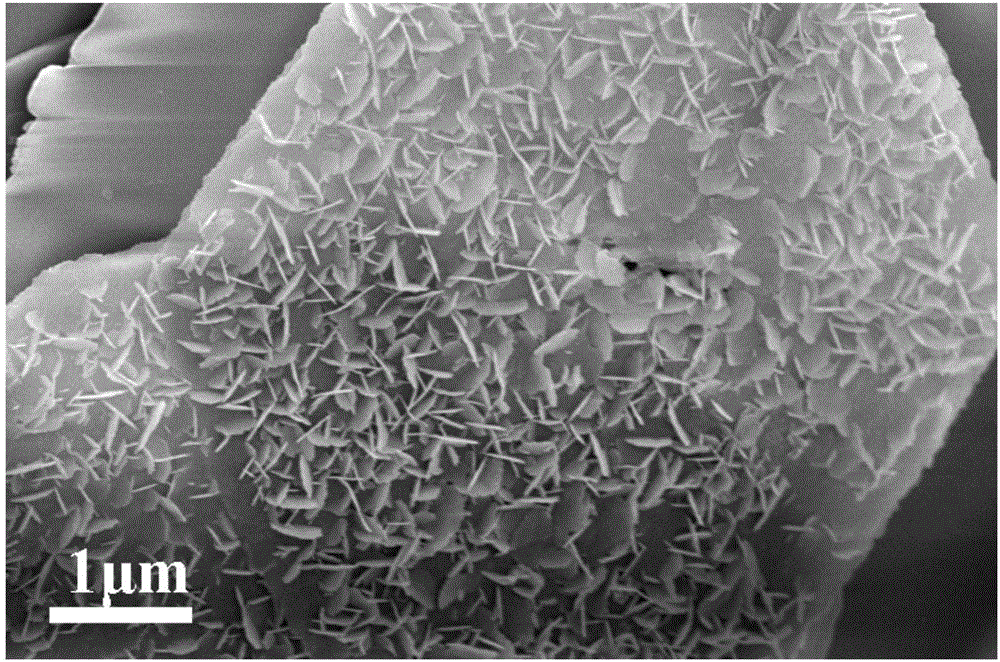

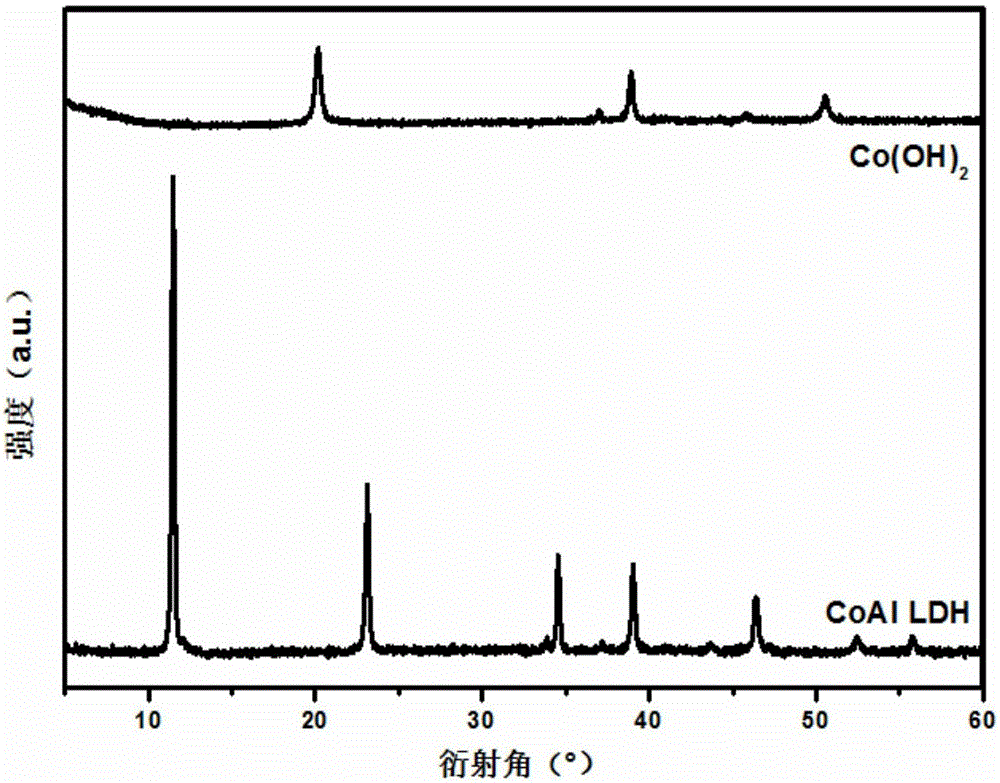

[0038] Adopt field emission scanning electron microscope (German Zeiss ultra 55) instrument, the cobalt aluminum double metal hydroxide powder of above-mentioned gained is scanned, and the scanning elect...

Embodiment 2

[0046] A multi-level structure cobalt hydroxide electrode material and a preparation method thereof, comprising the steps of:

[0047] (1) Preparation of cobalt-aluminum double metal hydroxide

[0048] a. First, at room temperature, add 20mg of cobalt nitrate and 10mg of aluminum nitrate into a 100ml beaker, and add 40ml of deionized water into it and stir for 20min to obtain a mixed solution;

[0049] b. Then add 10mg of urea to the above solution and stir for 20min;

[0050] c. Then move the above solution into a high-pressure reactor for hydrothermal reaction at a temperature of 100°C for 16 hours;

[0051] d. After the reaction, cool down to room temperature naturally, centrifuge and wash the sample, and then put it into a freeze dryer for freeze-drying for 30 hours;

[0052] (2) Preparation of multi-level structure cobalt hydroxide

[0053] a. First, add the above-mentioned cobalt-aluminum double metal hydroxide into a 500ml flask at room temperature, and add 100ml of ...

Embodiment 3

[0059] A multi-level structure cobalt hydroxide electrode material and a preparation method thereof, comprising the steps of:

[0060] (1) Preparation of cobalt-aluminum double metal hydroxide

[0061] a. First, at room temperature, add 30mg of cobalt nitrate and 20mg of aluminum nitrate into a 100ml beaker, and add 50ml of deionized water into it and stir for 25min to obtain a mixed solution;

[0062] b. Then add 10mg of urea to the above solution and stir for 25min;

[0063] c. Then transfer the above solution into a high-pressure reactor for hydrothermal reaction at a temperature of 110°C for 18 hours;

[0064] d. After the reaction, cool down to room temperature naturally, centrifuge and wash the sample, and then put it into a freeze dryer for freeze-drying for 36 hours;

[0065] (2) Preparation of multi-level structure cobalt hydroxide

[0066] a. First, add the above-mentioned cobalt-aluminum double metal hydroxide into a 500ml flask at room temperature, and add 150ml...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com