A kind of processing method of soybean powder and compound feed using the soybean powder

A technology of compound feed and processing method, applied in the direction of animal feed, animal feed, application, etc., can solve the problems of affecting feed quality, chemical residues, should not be used in large quantities, etc., to improve nutritional value, small inertia, and low operating costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A processing method of soybean flour, specifically comprising the following steps:

[0029]The first step is to obtain soybean processing raw materials: the soybean raw materials are firstly processed to obtain soybean processing raw materials, specifically: the soybean raw materials are first passed through a vibrating grading sieve to remove impurities; The soybeans in the silo pass through the stone remover and the permanent magnetic cylinder to remove the stones and iron slag in the soybeans to obtain soybean processing raw materials; the soybean raw materials used here are feed soybeans above grade two, and the total number of molds is ≤4×10 4 Individual / kg, aflatoxin ≤30μg / kg, crude protein ≥360g / kg;

[0030] The second step, infrared curing: the soybean processing raw materials obtained in the first step are sent to the infrared roasting device and heated by infrared radiation to obtain mature soybean materials. The total time is 60 seconds. The infrared baking ...

Embodiment 2- Embodiment 4

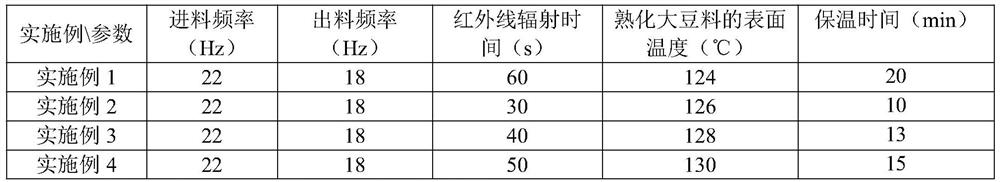

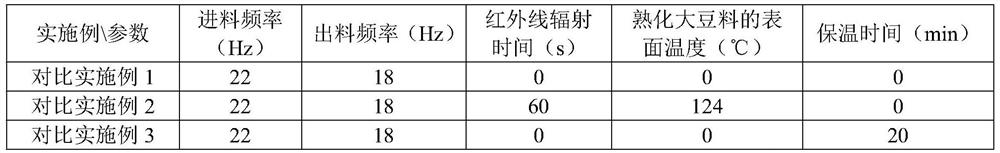

[0034] The difference between embodiment 2-embodiment 4 and embodiment 1 is that the infrared radiation time, the surface temperature of ripe soybean material and the heat preservation time, other are all identical with embodiment 1, see table 1 for details:

[0035] The parameter contrast table of table 1 embodiment 1-embodiment 4

[0036]

[0037] See Table 7 for details of the properties of the soybean flour obtained in Examples 2-Example 4.

Embodiment 5- Embodiment 8

[0039] The soybean meal of embodiment 1-embodiment 4 is used for making creep feed, and the formula (weight proportion) of creep feed is shown in table 2:

[0040] The formula of the creep feed of table 2 embodiment 5-embodiment 8 (only soybean flour is different)

[0041] raw material Proportion / % soy flour 15 wheat flour 6 broken rice 15 Wuliang peptide 10 corn 31.5 Imported fish powder 1 4 plasma protein powder 1.5 Simpler 1.5 Whey powder L 5 glucose 3 citric acid 1.5 Lysine 98 0.3 Choline chloride 0.1 arginine vitamin 0.05 Lishubao 0.05 salt 0.2 KZ-220-5 5

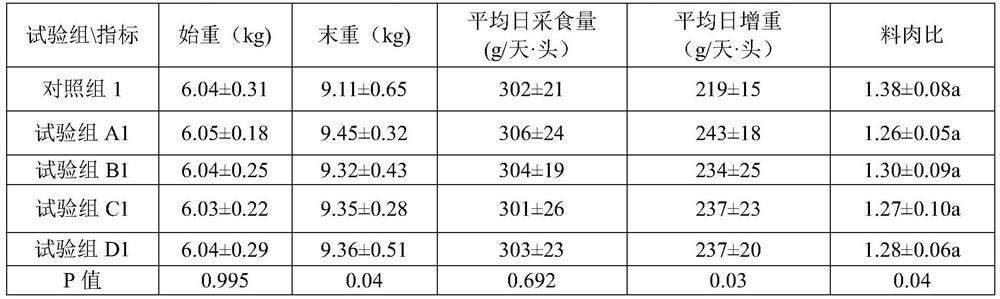

[0042] Adopt the creep feed of embodiment 5-embodiment 8 to carry out by a definite date the feeding test of 14 days, specifically: select 90 piglets (average body weight 6.04 ± 0.25kg) that are weaned at about 22-23 days of age and in good body condition, press Body weight similar principles are randoml...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com